Here’s what a good experienced human tuner can do

#1

A number of you have heard about the adventures I have had after getting a Harley 103 Stage 4 race (not street) kit installed in my 2014 Breakout. That long story, with multiple helpful (and some not so helpful ) comments from other forum members is detailed in my posting of about 5 or 6 weeks ago:

https://www.hdforums.com/forum/engin...questions.html

At the end of that posting thread, I had told readers I was trying to arrange for Mike Lozano, of Lozano Brothers fame, to tune my bike on his Dynojet, after he dynoed it for me during one of his shop’s monthly “dyno days”, and told me what he suspected was going on with both the shape and absolute numbers on my torque and power curves. But because of the Lozano Brothers’ great reputation, I had to wait 5 or 6 weeks for a spot to clear on Mike’s calendar. He got me in last Friday after returning from a multi-day trip to Atlanta during which he installed and tuned his shop’s unique dragracing clutch on a number of competitive dragracing machines for riders in that area.

Before he started the actual tune, Mike explained to me, first, why the absolute numbers on my bike’s torque and power were lower than I had expected after looking at HD’s Screamin’ Eagle catalog dyno chart for the Stage 4 Race kit.

First, he said, the Softail balancing assembly adds a tremendous amount of rotational inertia, which really hurts the bike on a “sweep” dyno run like the Dynojet dynoing process calls for, as it forces the engine to accelerate the entire drivetrain very rapidly, and the quicker the bike accelerates the drum, the more of its engine power is being diverted to also spin up the balancer assembly (which the unbalanced engines do not have). This is why tuners do the dyno runs on modern Harleys, balanced or unbalanced engines, in 5th gear versus 4th. In 4th gear, the bike can accelerate the drum more rapidly, which also forces the engine to accelerate its internal and drivetrain rotating parts faster, diverting more of the power to spinning up the drivetrain versus spinning up the drum. You can verify this by having your local tuner dynop your bike in 4th and then 5th. The 4th gear run will show lower power and torque.

Then Mike said that the really heavy HD Chrome Turbine rear wheel on my bike adds a tremendous amount of rotational inertia itself in addition, and I realized later back at home, it’s worse than the balancer, because although the engine balancer spins at crank rpm while the rear wheel spins at 1 / (2.78*1.19) = 30% of the engine crank’s rpm, the wheel diameter is several time larger than that of the balancer assembly, so the inertia effect is fairly large. (There is in fact a complex formula that allows you to calculate the inertia that the engine “sees’ for a wheel through a drivetrain, but that’s just plain masochistic to try to actually use – trust me, I’ve tried it in the past).

Mike told me that his past experience suggests that with my Softail balanced engine and that rear wheel, my reported power is going to run “at least” 6 to 8 rwhp lower than for a bike with an “A” (not internally balanced) engine and a more normal rear wheel. Applying that “penalty” to my last dyno chart makes the 104.4 rwhp that was reported on the dyno seem more understandable (104.4 + 6 to 8 rwhp = 110.4 to 112.4 rwhp on an A engine bike with normal wheel).

To really make the point about rotational inertia, Mike told me a story about a high power dragster bike that he and a friend had worked on. On that bike, the experimental substitution of a lightweight drive chain versus the "normal" (for that bike only!!) TRIPLE-plate chain, was enough to cause the bike to lose traction uncontrollably on launch because of the lower inertia of the lightweight chain!

Thinking about that further, I realized it is important to note that at low engine rpm, the 6 to 8% lower power numbers for a Softail with heavy rear wheel translate to torque numbers that are going to be notably lower than for an A engine. This is because the formula for torque is:

Torque = Power x 5252 / rpm

so at low rpm, where rpm is much smaller than 5252 – about half of 5252 – torque overwhelms power in the formula, so any absolute number difference in power in a Softail with heavy wheel is going to be accentuated in low rpm torque numbers. Ie. If the power loss is 6 to 8% at 6000 rpm, the loss in torque at low rpm is going to be several, not just a couple of, foot pounds.

Then, Mike talked about the shape of the torque (and therefore power) curve. He explained that the HD 259E camshafts in my bike have a very long intake duration that promotes high rpm filling of the cylinders, but in his experienced opinion, that cam keeps the intake open TOO long so that at lower engine rpm, the torque and therefore power fall off too much too fast compared to other cams whose duration is less extreme. He really prefers cams with about 4 degrees less duration for these engines.

He also noted that the 58mm throttle body is unnecessarily large for this engine and cam, and adversely hurts incoming charge velocity at high rpm (thus decreasing its momentum) and it really causes issues at low rpm where the volume of air is much lower to begin with. Mike says a 50mm throttle body would have been a better choice for HD to make for the Stage 4 kit.

Mike told me he was not at all surprised by the numbers my bike posted – they are pretty much exactly what he expects to see, and what he HAS seen on other Softails, but exaggerated further because of that heavy rear wheel.

Overall, Mike had no concerns about the peak power being off in any way. But he was very unhappy with the fall-off of the torque (and therefore also power) curve at 3500 rpm and below, even though he understood its cause (the 259E cam holding the intake open TOO long). He really wanted to focus on that, since a rider spends so much time in the 2000 to 3000 rpm range on the street, even though I knew I was buying a kit with a “high rpm” cam. He simply figured it would make the bike even better for me.

And, I believe Mike when he tells me all this, as he and his brothers have been building and tuning high performance car AND motorcycle engines for over 40 years, and their vehicles tend to WIN. For just ONE example of his engine building and tuning prowess, his own version of a Porsche V8 engine competed with and beat the Porsche factory sponsored engine in a Rolex race. If you want more on his credentials, Google “Lozano Brothers”, and check out what he and his brothers have done in both motorcycle and car racing, both personally and as retained engine and head suppliers to others. Mike has personally built and run dragbikes that ran in the 6s. Oh, and by the way, Mike recently took up a new hobby now that he “is a bit older” (he’s 63); he took up roadracing!

Once he had explained this all to me, Mike started the dyno tune:

I had bought a Power Vision PV-2 tuner for the bike, even though I already have an HD Super Tuner Pro, because Mike prefers the Power Vision, and also because I will later need to make a speedometer correction after Mike changes the final drive ratio for me. The Power Vision allows me to make that change by simply changing the Vehicle Speed Sensor factor field in the ECM, rather than buying an aftermarket speedometer correction device, so I save the cost of buying the aftermarket device and get a portion of the PV tuner “paid for” with that saving.

It took Mike over 3 ½ hours to tune my bike. He explained that because each tuner does a tune somewhat differently, starting with someone else’s earlier tune adds time instead of saving it, so he would NOT be starting with the Cowboy HD dealership tune, but rather he was starting with a Power Vision download file for a 110 cubic inch engine with many similarities to my own engine, the 2 into 1 exhaust similarity being an important factor in choosing a starting tune.

I also noticed how much time Mike devoted to the low rpm range and the multiple throttle openings at each rpm, followed by spark advance adjustments. He did the front cylinder first, and then the rear. When I say low rpm, I mean down to just above idle. When I asked why that amount of time at those really low engine rpm points, he explained that this would manifest as greatly improved performance right off a standing start in normal riding, and would also help clean up the nasty cold start problem that had appeared after the HD dealership Stage 4 custom tune (see later in this posting).

I noticed too that Mike, while very thorough, was also very efficient. He put on only a total of 46 odometer miles in the 3 ½ hours of dyno tuning. But because he knows what he is doing, I could visually SEE in the software display the perfect results he was getting at each and every combination of rpm point and throttle % open point.

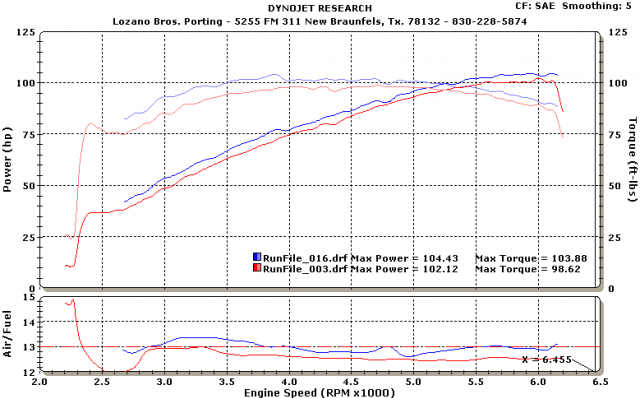

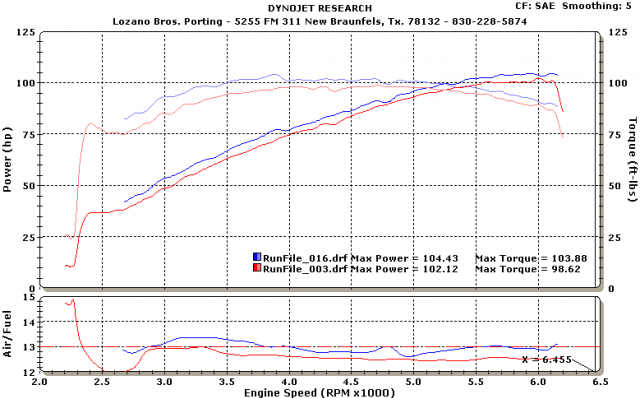

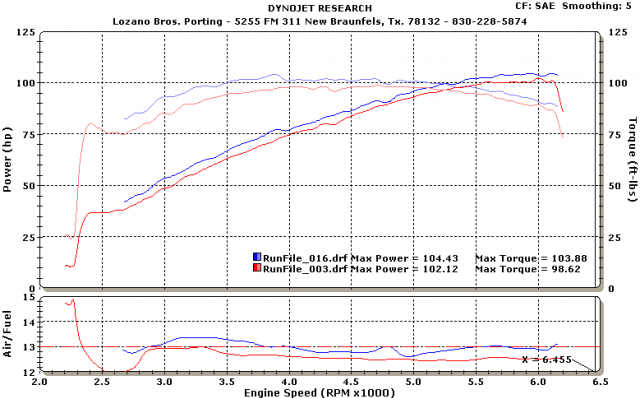

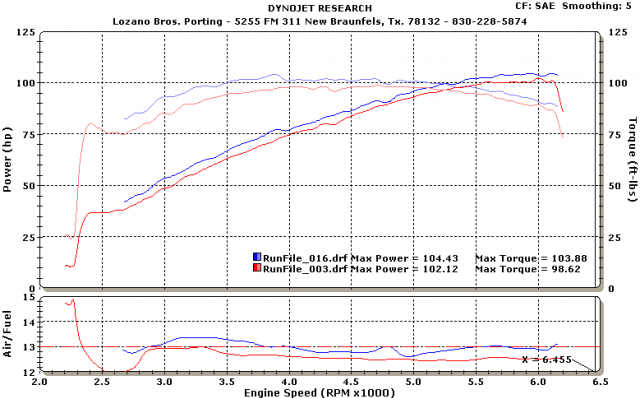

Here is a printout of his tuning results, which compares the original Cowboy dealership tune as captured by a dyno run on the Lozano Dynojet prior to Mike retuning the engine, compared to the results of Mike’s tune (on the same Lozano dynojet obviously):

Note first the virtually perfect “tabletop flat” torque curve in the 3500 to 5300 rpm range. This shape of curve is the ideal that every engine builder shoots for in an engine for a road bike that has to have more working range than a drag bike or road race bike, and that should not manifest sudden torque/power changes which can upset traction or front/rear weight distribution in cornering or on slippery road surfaces.

But there’s way more to notice here.

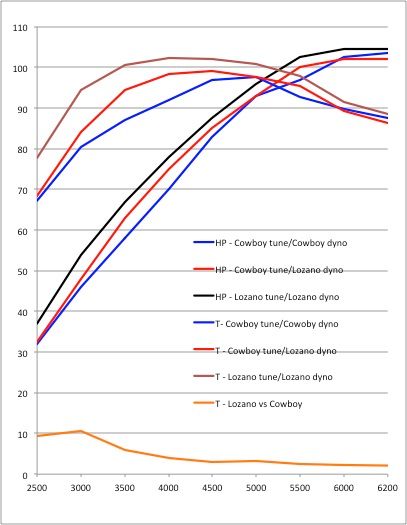

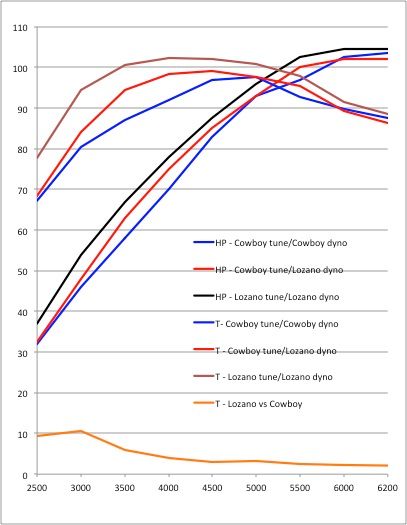

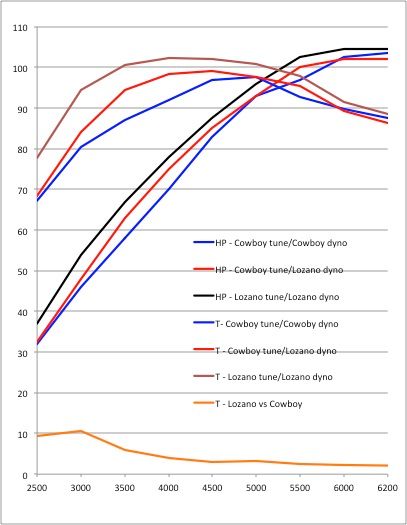

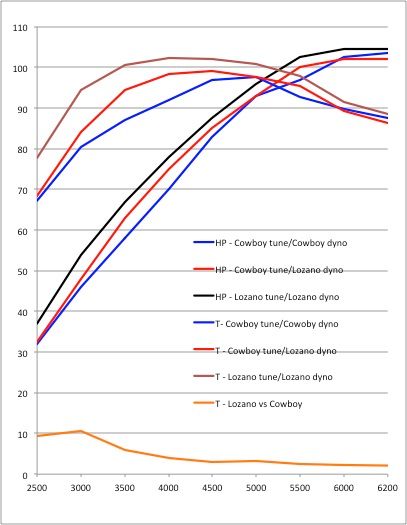

Here is a comparison graph that shows very clearly:

• The results of the Cowboy HD dealership tune as shown on the dealership Dynojet, using the dealership dyno technique

• The results of the Cowboy HD dealership tune as shown on the Lozano Dynojet (SAME tune, just dynoed on the Lozano dyno using Mike’s dyno technique vs dynoed on the Cowboy Dynojet using the dealership technique)

• The results of Mike’s tune on the Lozano dyno

The color coding got really badly screwed up by the process of converting my Mac Excel graph into a scrrenshot, and then via iPhoto into a jpg image, and then an upload into Photobucket, but here’s the easy way to know the difference between the 3 sets of lines:

The lowest line, whether power or torque, is always “blue” and is the Cowboy HD dealership tune result.

The middle line, always “red”, is the Cowboy tune properly dyoned on the Lozano Dynojet.

The top line is always the Lozano tune. The Brown curve is the Lozano torque curve. The Black curve is the Lozano power curve.

The orange curve near the bottom of the graph is the increase in torque that Mike Lozano got versus the Cowboy tune. (And, this is measured against the Cowboy tune as accurately reported on the Lozano dyno, not as defectively reported on the Cowboy dyno – see the discussion below to understand this.)

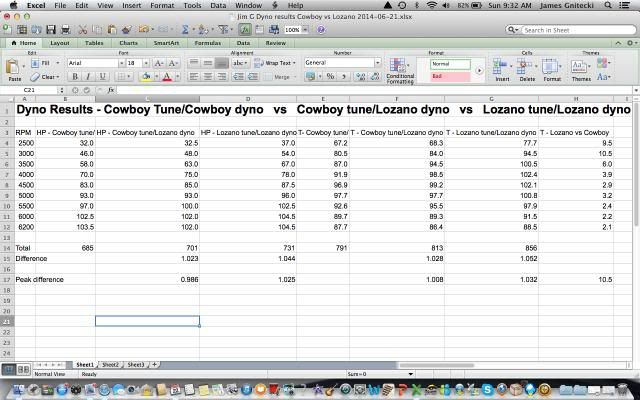

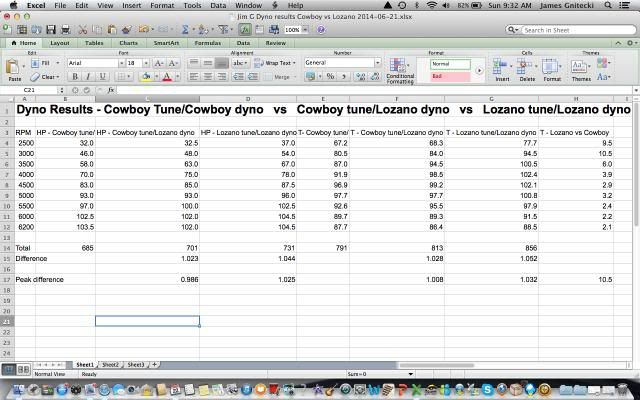

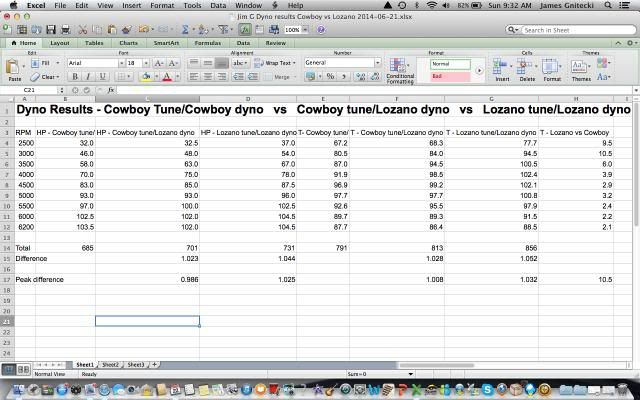

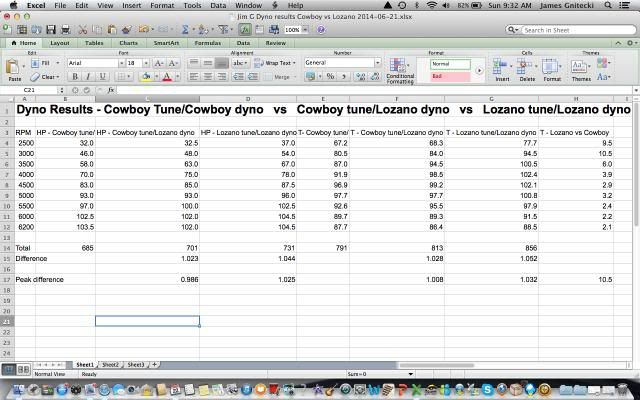

Here is the numerical data table for the above graph:

There are some very interesting attributes and facts within this table:

First, notice how different the torque and power curves look for the VERY SAME tune, when taken on the Lozano dyno versus the HD Cowboy dealership dyno (the red Lozano line versus the blue Cowboy line! This is pretty good proof that HOW a dyno run is performed has a disturbingly large effect on the absolute value and shape of the curves on a dyno chart. Remember, Mike made no changes when he ran my bike on his dyno with the Cowboy tune still in place on it, before he tuned it himself. Notice that the big differences are NOT in peak value, but rather in the low and mid rpm range. This pretty much proves that the differences are due to drivetrain inertia effects. These get magnified at low and medium rpm because the power diverted to spin up the drivetrain is a larger percentage of the total power available (Harley engines make way more power at high rpm than they do at low rpm, unless they have been equipped with a “torquer” cam).

I cannot know for sure, because Cowboy’s technician was unwilling to figure out how to email the raw Dynojet file to my email address where I could analyze it on my own computer using the free downloadable Dynojet software, but I strongly suspect that he incorrectly ran the bike in 4th gear versus 5th when he did that dyno run. That would have made the entire run much shorter in time, and would have forced the engine to accelerate the drivetrain much faster, diverting more of the power to that versus accelerating the dyno drum. That would explain the depressed low rpm torque and power curves nicely.

I should mention here that between The Cowboy HD dealership dyno runs and Mike’s runs, I had an opportunity to have the bike dynode on a 3rd dyno, at Phantom Rider, an independent shop, and Phantom’s result were very similar to the results that Mike got on his dyno before tuning the bike himself. This further supports the belief that the HD dealership run was done incorrectly.

If you are speculating that an unscrupulous dyno operator could distort the results of a before and after dyno tune via this technique (use 4th gear for “before” and 5th gear for “after”), you’d be correct. But I think in the case od the Cowboy HD dyno run, it was either lack of knowledge or simple error that the run was made in 4th gear.

Now notice how Mike was able to increase the peak power by only a couple of percent (2.5% per the actual data), but nevertheless, that is significant, as getting more power out of an engine at high rpm is not easy, and Mike did it via TUNING versus any parts changes

Mike GREATLY reduced the fall-off in torque and power at low rpm. In fact, at 2500 rpm and 3000 rpm, the gain was about 10 foot pounds of torque! At 3500, the gain was still 6 foot pounds! That’s a LOT to achieve via tuning, and a massive achievement given that Mike had to “fight” what the cam was doing at that rpm

Note the air/fuel ratio control he achieved. I had Mike use a deliberately very narrow vertical scale on that portion of the graph (AFR running from only 12 to 15), to magnify even small deviations, and still the AFR never gets above 13.4 and never gets below 12.6. The only reason it varies THAT much is that Mike is trying to give the engine what it wants at that rpm/throttle combination, not because he “missed” the 13.0 target.

Note how the engine’s torque never varies by more than a couple of foot pounds between 3500 and 5300 rpm! (disregard the transient that manifested at 3900 rpm – that’s not reproducible). That’s an impressive achievement, and the target HD was evidently aiming for with this kit, but it took Mike’s tuning skill to achieve it.

Engine designers like to talk about the “total area under the curve”. What they mean is the number that you get when you “count all the squares” under the torque curve or under the power curve, from the minimum testing rpm to the maximum testing rpm. This is a very meaningful number, because it shows how effectively the design of an engine, or engine kit, manages to pull power and torque out of the engine over the entire operating range of the engine.

When looking at “the area under the curve” for each of power and torque, Mike’s results are again very impressive.

Mike increased the area under the power curve by 4.4% over the HD dealership tune. In other words, on AVERAGE, the power after Mike’s tune was up by 4.4% despite the PEAK power being up only 2.5%. Note though that the increase over the power REPORTED by Cowboy HD is actually 6.7%, because the Cowboy dyno run underreported the low rpm performance because of what I speculated above is probably inertia effects caused by running the test in 4th gear versus 5th gear.

Mike increased the area under the torque curve by 5.2% over the HD dealership tune. Note though that the increase over the torque REPORTED by Cowboy HD is actually 8.2%, because the Cowboy dyno run was improperly done.

The increase achieved in area under the two curves, power versus torque, is different because Mike got relatively huge increases in torque at low rpm, and smaller ones at high rpm.

The rightmost column in the table shows Mike’s work beautifully isolated. He increased torque by about 10 ft lb in the 2500 and 3000 rpm ranges, by 6 ft lb at 3500 rpm, and by smaller amounts between 2 and 4 ft lb everywhere else.

Here’s a very important point: While Cowboy HD had set the AFR target as 13.X for many of the higher rpm / higher % throttle cells in the fuel tables, they left the AFR targets for much of the low and mid range rpm and % throttle cells as 14.7 ! That means the engine was doomed to run “hot” compared to the temperatures it would experience with a 13.X AFR target. I am giving them the benefit of the doubt when I say that they may have left the low and mid range cells at 14.7 for reasons of dealer compliance with EPA regulations.

So, how noticeable were the effects of Mike’s tuning?

Very. The tune transformed the bike.

I noticed WAY nicer throttle response getting the bike moving from a dead stop. I could feel the power increase immediately, right from when I let out the clutch at the door of Mike’s dyno room.

That nicer throttle response made sharp right turns from a dead stop, which I had been finding a bit difficult because of the bike’s tall gearing and the mediocre off-idle power, MUCH nicer.

The increase in rear wheel power in the 2000 to 3000 rpm range is very notable. In 5th gear now at 55 mph (2400 rpm), the throttle response is impressively better. In addition, it now feels like there is "more power than needed" when cruising in the 2000 to 3000 rpm range.

Throttle response from 2200 rpm in 5th, and even from 2200 rpm in 6th, is amazingly better. Throttle response from 2800 rpm is very crisp compared to before.

Moderate throttle acceleration up through the gears feels way better now. Very crisp.

Hard acceleration from a stop to highway speed is much more interesting now, despite the fact that the dyno chart improvements at higher rpm were small in comparison to the improvements at 1500 to 3000. The lofting of the front wheel is much more dramatic than it was before. I attribute this to better tuning of the extra shot of fuel that the ECM commands upon sudden acceleration (the equivalent of accelerator pump in a carburetor), and its effect as the bike slipped into each next gear and I reopened the throttle to full.

Oil temperature on my digital dipstick showed 237 after the ride home. The ambient outdoor temperature was 88 to 90 degrees. In weather like this, the oil temperature has been running 250 to as high as 270 previously, so I think the richer mixture (13.0 target versus 14.7) likely made a beneficial difference. This should have a very beneficial effect on oil life and engine life.

Before the tune, cold start behavior had been troublesome. It had been fine when the bike was briefly stock (for 68 odometer miles), and even after the Stage 4 kit had been installed and a canned tune provided for the duration of the break-in. But, after Cowboy HD did its Stage 4 dyno tune, the cold start behavior became very bad. The bike would immediately start, no problem, but then it would “hunt” between 2000 rpm and almost stalling, and often would need to be rescued from an imminent stall via hand throttle. The driveability was also very marginal for a couple of minutes.

The morning after Mike’s tune, I got an opportunity to do a cold, first-of-the day start, under exactly the same conditions as the prior morning BEFORE Mike’s tune. The difference was radical. No hunting. No threat of stalling. And here's the best part - after getting my helmet on, and getting onto the bike, I was able to pull away cleanly without any engine misbehavior whatsoever.

The off-idle throttle response and power, when starting from a dead stop, is dramatically better, so Mike’s time investment in that 1500 to 2000 rpm range was an excellent one. The improvement is notable enough that the tall first gear ratio is far less a concern now than it was. It is also terrifically useful on u-turns - I was able to execute a very tight radius u-turn the morning after the tune when a runners' race event police escort blocked the road I was on and I needed to turn around.

One big surprise: The difference in sound when cruising really surprises me. I wear a Schuberth helmet which very effectively attenuates the sharper, higher frequency exhaust sounds, while leaving the low frequency exhaust sounds. The tune has notably added to the sharp, higher frequency sounds. I had no idea a tune could affect the sound that much. It gives the phrase "exhaust tuning" a whole new dimension.

Let’s take a look now at fuel mileage. How bad can gas mileage get during a dyno tune? Well, pretty bad! I filled the tank 22 miles before I got to mike’s shop. Then, Mike put 46 miles on the bike during the dyno tuning. Then, I put on another 49 miles before I refilled the tank on the way home. The total miles covered was 117, and the fill-up required 4.25 gallons, so the net average for that tank was 27.6 mpg! It was actually far worse for the dyno tune itself, since the bike consistently averaged almost exactly 45.0 mpg before Mike’s tune, and so I KNOW therefore that I got 45 mpg for the first 22 miles of the tank, before the dyno tune.

So, basically that 22 miles used 0.5 gallon, so the remaining 117-22 = 95 miles that consisted of 46 miles of dyno tune plus 49 miles towards home, consumed 3.75 gallons, or 25.3 mpg!

But, how did Mike’s tune affect the ongoing “normal” fuel mileage? Well, after that first fill-up on the way home, I have only had to fill the bike once more, but that fill-up yielded 43.7 mpg. Not much of a difference, and in fact within the “variance rnage” for normal fill-ups. But I’ll need to see what the longer term average is before I can answer the question confidently.

For those wondering why fuel mileage did not plummet to match the 13.0 versus 14.7 AFR tuning targets, i.e. why didn’t it drop to 13.0/14.7 = 88.4% of previous mpg, or .884 x 45 = 39.8 mpg, the answer is simple. By tuning for a more effective AFR, Mike got more power out of each gallon of fuel. i.e. the engine runs more efficiently at AFR of 13.0 versus 14.7.

My overall conclusion about this tuning experience: Mike’s years of experience has really manifested on my bike. The bike is without exaggeration, transformed. If you have not yet had your bike hand tuned, don’t wait any longer. It’s very much worth doing.

Jim G

https://www.hdforums.com/forum/engin...questions.html

At the end of that posting thread, I had told readers I was trying to arrange for Mike Lozano, of Lozano Brothers fame, to tune my bike on his Dynojet, after he dynoed it for me during one of his shop’s monthly “dyno days”, and told me what he suspected was going on with both the shape and absolute numbers on my torque and power curves. But because of the Lozano Brothers’ great reputation, I had to wait 5 or 6 weeks for a spot to clear on Mike’s calendar. He got me in last Friday after returning from a multi-day trip to Atlanta during which he installed and tuned his shop’s unique dragracing clutch on a number of competitive dragracing machines for riders in that area.

Before he started the actual tune, Mike explained to me, first, why the absolute numbers on my bike’s torque and power were lower than I had expected after looking at HD’s Screamin’ Eagle catalog dyno chart for the Stage 4 Race kit.

First, he said, the Softail balancing assembly adds a tremendous amount of rotational inertia, which really hurts the bike on a “sweep” dyno run like the Dynojet dynoing process calls for, as it forces the engine to accelerate the entire drivetrain very rapidly, and the quicker the bike accelerates the drum, the more of its engine power is being diverted to also spin up the balancer assembly (which the unbalanced engines do not have). This is why tuners do the dyno runs on modern Harleys, balanced or unbalanced engines, in 5th gear versus 4th. In 4th gear, the bike can accelerate the drum more rapidly, which also forces the engine to accelerate its internal and drivetrain rotating parts faster, diverting more of the power to spinning up the drivetrain versus spinning up the drum. You can verify this by having your local tuner dynop your bike in 4th and then 5th. The 4th gear run will show lower power and torque.

Then Mike said that the really heavy HD Chrome Turbine rear wheel on my bike adds a tremendous amount of rotational inertia itself in addition, and I realized later back at home, it’s worse than the balancer, because although the engine balancer spins at crank rpm while the rear wheel spins at 1 / (2.78*1.19) = 30% of the engine crank’s rpm, the wheel diameter is several time larger than that of the balancer assembly, so the inertia effect is fairly large. (There is in fact a complex formula that allows you to calculate the inertia that the engine “sees’ for a wheel through a drivetrain, but that’s just plain masochistic to try to actually use – trust me, I’ve tried it in the past).

Mike told me that his past experience suggests that with my Softail balanced engine and that rear wheel, my reported power is going to run “at least” 6 to 8 rwhp lower than for a bike with an “A” (not internally balanced) engine and a more normal rear wheel. Applying that “penalty” to my last dyno chart makes the 104.4 rwhp that was reported on the dyno seem more understandable (104.4 + 6 to 8 rwhp = 110.4 to 112.4 rwhp on an A engine bike with normal wheel).

To really make the point about rotational inertia, Mike told me a story about a high power dragster bike that he and a friend had worked on. On that bike, the experimental substitution of a lightweight drive chain versus the "normal" (for that bike only!!) TRIPLE-plate chain, was enough to cause the bike to lose traction uncontrollably on launch because of the lower inertia of the lightweight chain!

Thinking about that further, I realized it is important to note that at low engine rpm, the 6 to 8% lower power numbers for a Softail with heavy rear wheel translate to torque numbers that are going to be notably lower than for an A engine. This is because the formula for torque is:

Torque = Power x 5252 / rpm

so at low rpm, where rpm is much smaller than 5252 – about half of 5252 – torque overwhelms power in the formula, so any absolute number difference in power in a Softail with heavy wheel is going to be accentuated in low rpm torque numbers. Ie. If the power loss is 6 to 8% at 6000 rpm, the loss in torque at low rpm is going to be several, not just a couple of, foot pounds.

Then, Mike talked about the shape of the torque (and therefore power) curve. He explained that the HD 259E camshafts in my bike have a very long intake duration that promotes high rpm filling of the cylinders, but in his experienced opinion, that cam keeps the intake open TOO long so that at lower engine rpm, the torque and therefore power fall off too much too fast compared to other cams whose duration is less extreme. He really prefers cams with about 4 degrees less duration for these engines.

He also noted that the 58mm throttle body is unnecessarily large for this engine and cam, and adversely hurts incoming charge velocity at high rpm (thus decreasing its momentum) and it really causes issues at low rpm where the volume of air is much lower to begin with. Mike says a 50mm throttle body would have been a better choice for HD to make for the Stage 4 kit.

Mike told me he was not at all surprised by the numbers my bike posted – they are pretty much exactly what he expects to see, and what he HAS seen on other Softails, but exaggerated further because of that heavy rear wheel.

Overall, Mike had no concerns about the peak power being off in any way. But he was very unhappy with the fall-off of the torque (and therefore also power) curve at 3500 rpm and below, even though he understood its cause (the 259E cam holding the intake open TOO long). He really wanted to focus on that, since a rider spends so much time in the 2000 to 3000 rpm range on the street, even though I knew I was buying a kit with a “high rpm” cam. He simply figured it would make the bike even better for me.

And, I believe Mike when he tells me all this, as he and his brothers have been building and tuning high performance car AND motorcycle engines for over 40 years, and their vehicles tend to WIN. For just ONE example of his engine building and tuning prowess, his own version of a Porsche V8 engine competed with and beat the Porsche factory sponsored engine in a Rolex race. If you want more on his credentials, Google “Lozano Brothers”, and check out what he and his brothers have done in both motorcycle and car racing, both personally and as retained engine and head suppliers to others. Mike has personally built and run dragbikes that ran in the 6s. Oh, and by the way, Mike recently took up a new hobby now that he “is a bit older” (he’s 63); he took up roadracing!

Once he had explained this all to me, Mike started the dyno tune:

I had bought a Power Vision PV-2 tuner for the bike, even though I already have an HD Super Tuner Pro, because Mike prefers the Power Vision, and also because I will later need to make a speedometer correction after Mike changes the final drive ratio for me. The Power Vision allows me to make that change by simply changing the Vehicle Speed Sensor factor field in the ECM, rather than buying an aftermarket speedometer correction device, so I save the cost of buying the aftermarket device and get a portion of the PV tuner “paid for” with that saving.

It took Mike over 3 ½ hours to tune my bike. He explained that because each tuner does a tune somewhat differently, starting with someone else’s earlier tune adds time instead of saving it, so he would NOT be starting with the Cowboy HD dealership tune, but rather he was starting with a Power Vision download file for a 110 cubic inch engine with many similarities to my own engine, the 2 into 1 exhaust similarity being an important factor in choosing a starting tune.

I also noticed how much time Mike devoted to the low rpm range and the multiple throttle openings at each rpm, followed by spark advance adjustments. He did the front cylinder first, and then the rear. When I say low rpm, I mean down to just above idle. When I asked why that amount of time at those really low engine rpm points, he explained that this would manifest as greatly improved performance right off a standing start in normal riding, and would also help clean up the nasty cold start problem that had appeared after the HD dealership Stage 4 custom tune (see later in this posting).

I noticed too that Mike, while very thorough, was also very efficient. He put on only a total of 46 odometer miles in the 3 ½ hours of dyno tuning. But because he knows what he is doing, I could visually SEE in the software display the perfect results he was getting at each and every combination of rpm point and throttle % open point.

Here is a printout of his tuning results, which compares the original Cowboy dealership tune as captured by a dyno run on the Lozano Dynojet prior to Mike retuning the engine, compared to the results of Mike’s tune (on the same Lozano dynojet obviously):

Note first the virtually perfect “tabletop flat” torque curve in the 3500 to 5300 rpm range. This shape of curve is the ideal that every engine builder shoots for in an engine for a road bike that has to have more working range than a drag bike or road race bike, and that should not manifest sudden torque/power changes which can upset traction or front/rear weight distribution in cornering or on slippery road surfaces.

But there’s way more to notice here.

Here is a comparison graph that shows very clearly:

• The results of the Cowboy HD dealership tune as shown on the dealership Dynojet, using the dealership dyno technique

• The results of the Cowboy HD dealership tune as shown on the Lozano Dynojet (SAME tune, just dynoed on the Lozano dyno using Mike’s dyno technique vs dynoed on the Cowboy Dynojet using the dealership technique)

• The results of Mike’s tune on the Lozano dyno

The color coding got really badly screwed up by the process of converting my Mac Excel graph into a scrrenshot, and then via iPhoto into a jpg image, and then an upload into Photobucket, but here’s the easy way to know the difference between the 3 sets of lines:

The lowest line, whether power or torque, is always “blue” and is the Cowboy HD dealership tune result.

The middle line, always “red”, is the Cowboy tune properly dyoned on the Lozano Dynojet.

The top line is always the Lozano tune. The Brown curve is the Lozano torque curve. The Black curve is the Lozano power curve.

The orange curve near the bottom of the graph is the increase in torque that Mike Lozano got versus the Cowboy tune. (And, this is measured against the Cowboy tune as accurately reported on the Lozano dyno, not as defectively reported on the Cowboy dyno – see the discussion below to understand this.)

Here is the numerical data table for the above graph:

There are some very interesting attributes and facts within this table:

First, notice how different the torque and power curves look for the VERY SAME tune, when taken on the Lozano dyno versus the HD Cowboy dealership dyno (the red Lozano line versus the blue Cowboy line! This is pretty good proof that HOW a dyno run is performed has a disturbingly large effect on the absolute value and shape of the curves on a dyno chart. Remember, Mike made no changes when he ran my bike on his dyno with the Cowboy tune still in place on it, before he tuned it himself. Notice that the big differences are NOT in peak value, but rather in the low and mid rpm range. This pretty much proves that the differences are due to drivetrain inertia effects. These get magnified at low and medium rpm because the power diverted to spin up the drivetrain is a larger percentage of the total power available (Harley engines make way more power at high rpm than they do at low rpm, unless they have been equipped with a “torquer” cam).

I cannot know for sure, because Cowboy’s technician was unwilling to figure out how to email the raw Dynojet file to my email address where I could analyze it on my own computer using the free downloadable Dynojet software, but I strongly suspect that he incorrectly ran the bike in 4th gear versus 5th when he did that dyno run. That would have made the entire run much shorter in time, and would have forced the engine to accelerate the drivetrain much faster, diverting more of the power to that versus accelerating the dyno drum. That would explain the depressed low rpm torque and power curves nicely.

I should mention here that between The Cowboy HD dealership dyno runs and Mike’s runs, I had an opportunity to have the bike dynode on a 3rd dyno, at Phantom Rider, an independent shop, and Phantom’s result were very similar to the results that Mike got on his dyno before tuning the bike himself. This further supports the belief that the HD dealership run was done incorrectly.

If you are speculating that an unscrupulous dyno operator could distort the results of a before and after dyno tune via this technique (use 4th gear for “before” and 5th gear for “after”), you’d be correct. But I think in the case od the Cowboy HD dyno run, it was either lack of knowledge or simple error that the run was made in 4th gear.

Now notice how Mike was able to increase the peak power by only a couple of percent (2.5% per the actual data), but nevertheless, that is significant, as getting more power out of an engine at high rpm is not easy, and Mike did it via TUNING versus any parts changes

Mike GREATLY reduced the fall-off in torque and power at low rpm. In fact, at 2500 rpm and 3000 rpm, the gain was about 10 foot pounds of torque! At 3500, the gain was still 6 foot pounds! That’s a LOT to achieve via tuning, and a massive achievement given that Mike had to “fight” what the cam was doing at that rpm

Note the air/fuel ratio control he achieved. I had Mike use a deliberately very narrow vertical scale on that portion of the graph (AFR running from only 12 to 15), to magnify even small deviations, and still the AFR never gets above 13.4 and never gets below 12.6. The only reason it varies THAT much is that Mike is trying to give the engine what it wants at that rpm/throttle combination, not because he “missed” the 13.0 target.

Note how the engine’s torque never varies by more than a couple of foot pounds between 3500 and 5300 rpm! (disregard the transient that manifested at 3900 rpm – that’s not reproducible). That’s an impressive achievement, and the target HD was evidently aiming for with this kit, but it took Mike’s tuning skill to achieve it.

Engine designers like to talk about the “total area under the curve”. What they mean is the number that you get when you “count all the squares” under the torque curve or under the power curve, from the minimum testing rpm to the maximum testing rpm. This is a very meaningful number, because it shows how effectively the design of an engine, or engine kit, manages to pull power and torque out of the engine over the entire operating range of the engine.

When looking at “the area under the curve” for each of power and torque, Mike’s results are again very impressive.

Mike increased the area under the power curve by 4.4% over the HD dealership tune. In other words, on AVERAGE, the power after Mike’s tune was up by 4.4% despite the PEAK power being up only 2.5%. Note though that the increase over the power REPORTED by Cowboy HD is actually 6.7%, because the Cowboy dyno run underreported the low rpm performance because of what I speculated above is probably inertia effects caused by running the test in 4th gear versus 5th gear.

Mike increased the area under the torque curve by 5.2% over the HD dealership tune. Note though that the increase over the torque REPORTED by Cowboy HD is actually 8.2%, because the Cowboy dyno run was improperly done.

The increase achieved in area under the two curves, power versus torque, is different because Mike got relatively huge increases in torque at low rpm, and smaller ones at high rpm.

The rightmost column in the table shows Mike’s work beautifully isolated. He increased torque by about 10 ft lb in the 2500 and 3000 rpm ranges, by 6 ft lb at 3500 rpm, and by smaller amounts between 2 and 4 ft lb everywhere else.

Here’s a very important point: While Cowboy HD had set the AFR target as 13.X for many of the higher rpm / higher % throttle cells in the fuel tables, they left the AFR targets for much of the low and mid range rpm and % throttle cells as 14.7 ! That means the engine was doomed to run “hot” compared to the temperatures it would experience with a 13.X AFR target. I am giving them the benefit of the doubt when I say that they may have left the low and mid range cells at 14.7 for reasons of dealer compliance with EPA regulations.

So, how noticeable were the effects of Mike’s tuning?

Very. The tune transformed the bike.

I noticed WAY nicer throttle response getting the bike moving from a dead stop. I could feel the power increase immediately, right from when I let out the clutch at the door of Mike’s dyno room.

That nicer throttle response made sharp right turns from a dead stop, which I had been finding a bit difficult because of the bike’s tall gearing and the mediocre off-idle power, MUCH nicer.

The increase in rear wheel power in the 2000 to 3000 rpm range is very notable. In 5th gear now at 55 mph (2400 rpm), the throttle response is impressively better. In addition, it now feels like there is "more power than needed" when cruising in the 2000 to 3000 rpm range.

Throttle response from 2200 rpm in 5th, and even from 2200 rpm in 6th, is amazingly better. Throttle response from 2800 rpm is very crisp compared to before.

Moderate throttle acceleration up through the gears feels way better now. Very crisp.

Hard acceleration from a stop to highway speed is much more interesting now, despite the fact that the dyno chart improvements at higher rpm were small in comparison to the improvements at 1500 to 3000. The lofting of the front wheel is much more dramatic than it was before. I attribute this to better tuning of the extra shot of fuel that the ECM commands upon sudden acceleration (the equivalent of accelerator pump in a carburetor), and its effect as the bike slipped into each next gear and I reopened the throttle to full.

Oil temperature on my digital dipstick showed 237 after the ride home. The ambient outdoor temperature was 88 to 90 degrees. In weather like this, the oil temperature has been running 250 to as high as 270 previously, so I think the richer mixture (13.0 target versus 14.7) likely made a beneficial difference. This should have a very beneficial effect on oil life and engine life.

Before the tune, cold start behavior had been troublesome. It had been fine when the bike was briefly stock (for 68 odometer miles), and even after the Stage 4 kit had been installed and a canned tune provided for the duration of the break-in. But, after Cowboy HD did its Stage 4 dyno tune, the cold start behavior became very bad. The bike would immediately start, no problem, but then it would “hunt” between 2000 rpm and almost stalling, and often would need to be rescued from an imminent stall via hand throttle. The driveability was also very marginal for a couple of minutes.

The morning after Mike’s tune, I got an opportunity to do a cold, first-of-the day start, under exactly the same conditions as the prior morning BEFORE Mike’s tune. The difference was radical. No hunting. No threat of stalling. And here's the best part - after getting my helmet on, and getting onto the bike, I was able to pull away cleanly without any engine misbehavior whatsoever.

The off-idle throttle response and power, when starting from a dead stop, is dramatically better, so Mike’s time investment in that 1500 to 2000 rpm range was an excellent one. The improvement is notable enough that the tall first gear ratio is far less a concern now than it was. It is also terrifically useful on u-turns - I was able to execute a very tight radius u-turn the morning after the tune when a runners' race event police escort blocked the road I was on and I needed to turn around.

One big surprise: The difference in sound when cruising really surprises me. I wear a Schuberth helmet which very effectively attenuates the sharper, higher frequency exhaust sounds, while leaving the low frequency exhaust sounds. The tune has notably added to the sharp, higher frequency sounds. I had no idea a tune could affect the sound that much. It gives the phrase "exhaust tuning" a whole new dimension.

Let’s take a look now at fuel mileage. How bad can gas mileage get during a dyno tune? Well, pretty bad! I filled the tank 22 miles before I got to mike’s shop. Then, Mike put 46 miles on the bike during the dyno tuning. Then, I put on another 49 miles before I refilled the tank on the way home. The total miles covered was 117, and the fill-up required 4.25 gallons, so the net average for that tank was 27.6 mpg! It was actually far worse for the dyno tune itself, since the bike consistently averaged almost exactly 45.0 mpg before Mike’s tune, and so I KNOW therefore that I got 45 mpg for the first 22 miles of the tank, before the dyno tune.

So, basically that 22 miles used 0.5 gallon, so the remaining 117-22 = 95 miles that consisted of 46 miles of dyno tune plus 49 miles towards home, consumed 3.75 gallons, or 25.3 mpg!

But, how did Mike’s tune affect the ongoing “normal” fuel mileage? Well, after that first fill-up on the way home, I have only had to fill the bike once more, but that fill-up yielded 43.7 mpg. Not much of a difference, and in fact within the “variance rnage” for normal fill-ups. But I’ll need to see what the longer term average is before I can answer the question confidently.

For those wondering why fuel mileage did not plummet to match the 13.0 versus 14.7 AFR tuning targets, i.e. why didn’t it drop to 13.0/14.7 = 88.4% of previous mpg, or .884 x 45 = 39.8 mpg, the answer is simple. By tuning for a more effective AFR, Mike got more power out of each gallon of fuel. i.e. the engine runs more efficiently at AFR of 13.0 versus 14.7.

My overall conclusion about this tuning experience: Mike’s years of experience has really manifested on my bike. The bike is without exaggeration, transformed. If you have not yet had your bike hand tuned, don’t wait any longer. It’s very much worth doing.

Jim G

#2

#4

1. Simple error - thought he was in 5th, and never did the quality check quick scan of the dyno screen after the run to make sure he was

2. Wanted to keep the tire speed lower than would be necessary in 5th in order to hit peak engine rpm (liability conscious dealerships don't like to run a customer's rear tire on a dyno at high speed for fear it is not in great condition and could fail, either right then, or worse, right after on the customer's way home).

3. Ignorance. The technician does not realize that a lower gear produces a lower power reading. I'm not kidding.

Jim G

#5

#7

A number of you have heard about the adventures I have had after getting a Harley 103 Stage 4 race (not street) kit installed in my 2014 Breakout. That long story, with multiple helpful (and some not so helpful ) comments from other forum members is detailed in my posting of about 5 or 6 weeks ago:

https://www.hdforums.com/forum/engin...questions.html

At the end of that posting thread, I had told readers I was trying to arrange for Mike Lozano, of Lozano Brothers fame, to tune my bike on his Dynojet, after he dynoed it for me during one of his shop’s monthly “dyno days”, and told me what he suspected was going on with both the shape and absolute numbers on my torque and power curves. But because of the Lozano Brothers’ great reputation, I had to wait 5 or 6 weeks for a spot to clear on Mike’s calendar. He got me in last Friday after returning from a multi-day trip to Atlanta during which he installed and tuned his shop’s unique dragracing clutch on a number of competitive dragracing machines for riders in that area.

Before he started the actual tune, Mike explained to me, first, why the absolute numbers on my bike’s torque and power were lower than I had expected after looking at HD’s Screamin’ Eagle catalog dyno chart for the Stage 4 Race kit.

First, he said, the Softail balancing assembly adds a tremendous amount of rotational inertia, which really hurts the bike on a “sweep” dyno run like the Dynojet dynoing process calls for, as it forces the engine to accelerate the entire drivetrain very rapidly, and the quicker the bike accelerates the drum, the more of its engine power is being diverted to also spin up the balancer assembly (which the unbalanced engines do not have). This is why tuners do the dyno runs on modern Harleys, balanced or unbalanced engines, in 5th gear versus 4th. In 4th gear, the bike can accelerate the drum more rapidly, which also forces the engine to accelerate its internal and drivetrain rotating parts faster, diverting more of the power to spinning up the drivetrain versus spinning up the drum. You can verify this by having your local tuner dynop your bike in 4th and then 5th. The 4th gear run will show lower power and torque.

Then Mike said that the really heavy HD Chrome Turbine rear wheel on my bike adds a tremendous amount of rotational inertia itself in addition, and I realized later back at home, it’s worse than the balancer, because although the engine balancer spins at crank rpm while the rear wheel spins at 1 / (2.78*1.19) = 30% of the engine crank’s rpm, the wheel diameter is several time larger than that of the balancer assembly, so the inertia effect is fairly large. (There is in fact a complex formula that allows you to calculate the inertia that the engine “sees’ for a wheel through a drivetrain, but that’s just plain masochistic to try to actually use – trust me, I’ve tried it in the past).

Mike told me that his past experience suggests that with my Softail balanced engine and that rear wheel, my reported power is going to run “at least” 6 to 8 rwhp lower than for a bike with an “A” (not internally balanced) engine and a more normal rear wheel. Applying that “penalty” to my last dyno chart makes the 104.4 rwhp that was reported on the dyno seem more understandable (104.4 + 6 to 8 rwhp = 110.4 to 112.4 rwhp on an A engine bike with normal wheel).

To really make the point about rotational inertia, Mike told me a story about a high power dragster bike that he and a friend had worked on. On that bike, the experimental substitution of a lightweight drive chain versus the "normal" (for that bike only!!) TRIPLE-plate chain, was enough to cause the bike to lose traction uncontrollably on launch because of the lower inertia of the lightweight chain!

Thinking about that further, I realized it is important to note that at low engine rpm, the 6 to 8% lower power numbers for a Softail with heavy rear wheel translate to torque numbers that are going to be notably lower than for an A engine. This is because the formula for torque is:

Torque = Power x 5252 / rpm

so at low rpm, where rpm is much smaller than 5252 – about half of 5252 – torque overwhelms power in the formula, so any absolute number difference in power in a Softail with heavy wheel is going to be accentuated in low rpm torque numbers. Ie. If the power loss is 6 to 8% at 6000 rpm, the loss in torque at low rpm is going to be several, not just a couple of, foot pounds.

Then, Mike talked about the shape of the torque (and therefore power) curve. He explained that the HD 259E camshafts in my bike have a very long intake duration that promotes high rpm filling of the cylinders, but in his experienced opinion, that cam keeps the intake open TOO long so that at lower engine rpm, the torque and therefore power fall off too much too fast compared to other cams whose duration is less extreme. He really prefers cams with about 4 degrees less duration for these engines.

He also noted that the 58mm throttle body is unnecessarily large for this engine and cam, and adversely hurts incoming charge velocity at high rpm (thus decreasing its momentum) and it really causes issues at low rpm where the volume of air is much lower to begin with. Mike says a 50mm throttle body would have been a better choice for HD to make for the Stage 4 kit.

Mike told me he was not at all surprised by the numbers my bike posted – they are pretty much exactly what he expects to see, and what he HAS seen on other Softails, but exaggerated further because of that heavy rear wheel.

Overall, Mike had no concerns about the peak power being off in any way. But he was very unhappy with the fall-off of the torque (and therefore also power) curve at 3500 rpm and below, even though he understood its cause (the 259E cam holding the intake open TOO long). He really wanted to focus on that, since a rider spends so much time in the 2000 to 3000 rpm range on the street, even though I knew I was buying a kit with a “high rpm” cam. He simply figured it would make the bike even better for me.

And, I believe Mike when he tells me all this, as he and his brothers have been building and tuning high performance car AND motorcycle engines for over 40 years, and their vehicles tend to WIN. For just ONE example of his engine building and tuning prowess, his own version of a Porsche V8 engine competed with and beat the Porsche factory sponsored engine in a Rolex race. If you want more on his credentials, Google “Lozano Brothers”, and check out what he and his brothers have done in both motorcycle and car racing, both personally and as retained engine and head suppliers to others. Mike has personally built and run dragbikes that ran in the 6s. Oh, and by the way, Mike recently took up a new hobby now that he “is a bit older” (he’s 63); he took up roadracing!

Once he had explained this all to me, Mike started the dyno tune:

I had bought a Power Vision PV-2 tuner for the bike, even though I already have an HD Super Tuner Pro, because Mike prefers the Power Vision, and also because I will later need to make a speedometer correction after Mike changes the final drive ratio for me. The Power Vision allows me to make that change by simply changing the Vehicle Speed Sensor factor field in the ECM, rather than buying an aftermarket speedometer correction device, so I save the cost of buying the aftermarket device and get a portion of the PV tuner “paid for” with that saving.

It took Mike over 3 ½ hours to tune my bike. He explained that because each tuner does a tune somewhat differently, starting with someone else’s earlier tune adds time instead of saving it, so he would NOT be starting with the Cowboy HD dealership tune, but rather he was starting with a Power Vision download file for a 110 cubic inch engine with many similarities to my own engine, the 2 into 1 exhaust similarity being an important factor in choosing a starting tune.

I also noticed how much time Mike devoted to the low rpm range and the multiple throttle openings at each rpm, followed by spark advance adjustments. He did the front cylinder first, and then the rear. When I say low rpm, I mean down to just above idle. When I asked why that amount of time at those really low engine rpm points, he explained that this would manifest as greatly improved performance right off a standing start in normal riding, and would also help clean up the nasty cold start problem that had appeared after the HD dealership Stage 4 custom tune (see later in this posting).

I noticed too that Mike, while very thorough, was also very efficient. He put on only a total of 46 odometer miles in the 3 ½ hours of dyno tuning. But because he knows what he is doing, I could visually SEE in the software display the perfect results he was getting at each and every combination of rpm point and throttle % open point.

Here is a printout of his tuning results, which compares the original Cowboy dealership tune as captured by a dyno run on the Lozano Dynojet prior to Mike retuning the engine, compared to the results of Mike’s tune (on the same Lozano dynojet obviously):

Note first the virtually perfect “tabletop flat” torque curve in the 3500 to 5300 rpm range. This shape of curve is the ideal that every engine builder shoots for in an engine for a road bike that has to have more working range than a drag bike or road race bike, and that should not manifest sudden torque/power changes which can upset traction or front/rear weight distribution in cornering or on slippery road surfaces.

But there’s way more to notice here.

Here is a comparison graph that shows very clearly:

• The results of the Cowboy HD dealership tune as shown on the dealership Dynojet, using the dealership dyno technique

• The results of the Cowboy HD dealership tune as shown on the Lozano Dynojet (SAME tune, just dynoed on the Lozano dyno using Mike’s dyno technique vs dynoed on the Cowboy Dynojet using the dealership technique)

• The results of Mike’s tune on the Lozano dyno

The color coding got really badly screwed up by the process of converting my Mac Excel graph into a scrrenshot, and then via iPhoto into a jpg image, and then an upload into Photobucket, but here’s the easy way to know the difference between the 3 sets of lines:

The lowest line, whether power or torque, is always “blue” and is the Cowboy HD dealership tune result.

The middle line, always “red”, is the Cowboy tune properly dyoned on the Lozano Dynojet.

The top line is always the Lozano tune. The Brown curve is the Lozano torque curve. The Black curve is the Lozano power curve.

The orange curve near the bottom of the graph is the increase in torque that Mike Lozano got versus the Cowboy tune. (And, this is measured against the Cowboy tune as accurately reported on the Lozano dyno, not as defectively reported on the Cowboy dyno – see the discussion below to understand this.)

Here is the numerical data table for the above graph:

There are some very interesting attributes and facts within this table:

First, notice how different the torque and power curves look for the VERY SAME tune, when taken on the Lozano dyno versus the HD Cowboy dealership dyno (the red Lozano line versus the blue Cowboy line! This is pretty good proof that HOW a dyno run is performed has a disturbingly large effect on the absolute value and shape of the curves on a dyno chart. Remember, Mike made no changes when he ran my bike on his dyno with the Cowboy tune still in place on it, before he tuned it himself. Notice that the big differences are NOT in peak value, but rather in the low and mid rpm range. This pretty much proves that the differences are due to drivetrain inertia effects. These get magnified at low and medium rpm because the power diverted to spin up the drivetrain is a larger percentage of the total power available (Harley engines make way more power at high rpm than they do at low rpm, unless they have been equipped with a “torquer” cam).

I cannot know for sure, because Cowboy’s technician was unwilling to figure out how to email the raw Dynojet file to my email address where I could analyze it on my own computer using the free downloadable Dynojet software, but I strongly suspect that he incorrectly ran the bike in 4th gear versus 5th when he did that dyno run. That would have made the entire run much shorter in time, and would have forced the engine to accelerate the drivetrain much faster, diverting more of the power to that versus accelerating the dyno drum. That would explain the depressed low rpm torque and power curves nicely.

I should mention here that between The Cowboy HD dealership dyno runs and Mike’s runs, I had an opportunity to have the bike dynode on a 3rd dyno, at Phantom Rider, an independent shop, and Phantom’s result were very similar to the results that Mike got on his dyno before tuning the bike himself. This further supports the belief that the HD dealership run was done incorrectly.

If you are speculating that an unscrupulous dyno operator could distort the results of a before and after dyno tune via this technique (use 4th gear for “before” and 5th gear for “after”), you’d be correct. But I think in the case od the Cowboy HD dyno run, it was either lack of knowledge or simple error that the run was made in 4th gear.

Now notice how Mike was able to increase the peak power by only a couple of percent (2.5% per the actual data), but nevertheless, that is significant, as getting more power out of an engine at high rpm is not easy, and Mike did it via TUNING versus any parts changes

Mike GREATLY reduced the fall-off in torque and power at low rpm. In fact, at 2500 rpm and 3000 rpm, the gain was about 10 foot pounds of torque! At 3500, the gain was still 6 foot pounds! That’s a LOT to achieve via tuning, and a massive achievement given that Mike had to “fight” what the cam was doing at that rpm

Note the air/fuel ratio control he achieved. I had Mike use a deliberately very narrow vertical scale on that portion of the graph (AFR running from only 12 to 15), to magnify even small deviations, and still the AFR never gets above 13.4 and never gets below 12.6. The only reason it varies THAT much is that Mike is trying to give the engine what it wants at that rpm/throttle combination, not because he “missed” the 13.0 target.

Note how the engine’s torque never varies by more than a couple of foot pounds between 3500 and 5300 rpm! (disregard the transient that manifested at 3900 rpm – that’s not reproducible). That’s an impressive achievement, and the target HD was evidently aiming for with this kit, but it took Mike’s tuning skill to achieve it.

Engine designers like to talk about the “total area under the curve”. What they mean is the number that you get when you “count all the squares” under the torque curve or under the power curve, from the minimum testing rpm to the maximum testing rpm. This is a very meaningful number, because it shows how effectively the design of an engine, or engine kit, manages to pull power and torque out of the engine over the entire operating range of the engine.

When looking at “the area under the curve” for each of power and torque, Mike’s results are again very impressive.

Mike increased the area under the power curve by 4.4% over the HD dealership tune. In other words, on AVERAGE, the power after Mike’s tune was up by 4.4% despite the PEAK power being up only 2.5%. Note though that the increase over the power REPORTED by Cowboy HD is actually 6.7%, because the Cowboy dyno run underreported the low rpm performance because of what I speculated above is probably inertia effects caused by running the test in 4th gear versus 5th gear.

Mike increased the area under the torque curve by 5.2% over the HD dealership tune. Note though that the increase over the torque REPORTED by Cowboy HD is actually 8.2%, because the Cowboy dyno run was improperly done.

The increase achieved in area under the two curves, power versus torque, is different because Mike got relatively huge increases in torque at low rpm, and smaller ones at high rpm.

The rightmost column in the table shows Mike’s work beautifully isolated. He increased torque by about 10 ft lb in the 2500 and 3000 rpm ranges, by 6 ft lb at 3500 rpm, and by smaller amounts between 2 and 4 ft lb everywhere else.

Here’s a very important point: While Cowboy HD had set the AFR target as 13.X for many of the higher rpm / higher % throttle cells in the fuel tables, they left the AFR targets for much of the low and mid range rpm and % throttle cells as 14.7 ! That means the engine was doomed to run “hot” compared to the temperatures it would experience with a 13.X AFR target. I am giving them the benefit of the doubt when I say that they may have left the low and mid range cells at 14.7 for reasons of dealer compliance with EPA regulations.

So, how noticeable were the effects of Mike’s tuning?

Very. The tune transformed the bike.

I noticed WAY nicer throttle response getting the bike moving from a dead stop. I could feel the power increase immediately, right from when I let out the clutch at the door of Mike’s dyno room.

That nicer throttle response made sharp right turns from a dead stop, which I had been finding a bit difficult because of the bike’s tall gearing and the mediocre off-idle power, MUCH nicer.

The increase in rear wheel power in the 2000 to 3000 rpm range is very notable. In 5th gear now at 55 mph (2400 rpm), the throttle response is impressively better. In addition, it now feels like there is "more power than needed" when cruising in the 2000 to 3000 rpm range.

Throttle response from 2200 rpm in 5th, and even from 2200 rpm in 6th, is amazingly better. Throttle response from 2800 rpm is very crisp compared to before.

Moderate throttle acceleration up through the gears feels way better now. Very crisp.

Hard acceleration from a stop to highway speed is much more interesting now, despite the fact that the dyno chart improvements at higher rpm were small in comparison to the improvements at 1500 to 3000. The lofting of the front wheel is much more dramatic than it was before. I attribute this to better tuning of the extra shot of fuel that the ECM commands upon sudden acceleration (the equivalent of accelerator pump in a carburetor), and its effect as the bike slipped into each next gear and I reopened the throttle to full.

Oil temperature on my digital dipstick showed 237 after the ride home. The ambient outdoor temperature was 88 to 90 degrees. In weather like this, the oil temperature has been running 250 to as high as 270 previously, so I think the richer mixture (13.0 target versus 14.7) likely made a beneficial difference. This should have a very beneficial effect on oil life and engine life.

Before the tune, cold start behavior had been troublesome. It had been fine when the bike was briefly stock (for 68 odometer miles), and even after the Stage 4 kit had been installed and a canned tune provided for the duration of the break-in. But, after Cowboy HD did its Stage 4 dyno tune, the cold start behavior became very bad. The bike would immediately start, no problem, but then it would “hunt” between 2000 rpm and almost stalling, and often would need to be rescued from an imminent stall via hand throttle. The driveability was also very marginal for a couple of minutes.

The morning after Mike’s tune, I got an opportunity to do a cold, first-of-the day start, under exactly the same conditions as the prior morning BEFORE Mike’s tune. The difference was radical. No hunting. No threat of stalling. And here's the best part - after getting my helmet on, and getting onto the bike, I was able to pull away cleanly without any engine misbehavior whatsoever.

The off-idle throttle response and power, when starting from a dead stop, is dramatically better, so Mike’s time investment in that 1500 to 2000 rpm range was an excellent one. The improvement is notable enough that the tall first gear ratio is far less a concern now than it was. It is also terrifically useful on u-turns - I was able to execute a very tight radius u-turn the morning after the tune when a runners' race event police escort blocked the road I was on and I needed to turn around.

One big surprise: The difference in sound when cruising really surprises me. I wear a Schuberth helmet which very effectively attenuates the sharper, higher frequency exhaust sounds, while leaving the low frequency exhaust sounds. The tune has notably added to the sharp, higher frequency sounds. I had no idea a tune could affect the sound that much. It gives the phrase "exhaust tuning" a whole new dimension.

Let’s take a look now at fuel mileage. How bad can gas mileage get during a dyno tune? Well, pretty bad! I filled the tank 22 miles before I got to mike’s shop. Then, Mike put 46 miles on the bike during the dyno tuning. Then, I put on another 49 miles before I refilled the tank on the way home. The total miles covered was 117, and the fill-up required 4.25 gallons, so the net average for that tank was 27.6 mpg! It was actually far worse for the dyno tune itself, since the bike consistently averaged almost exactly 45.0 mpg before Mike’s tune, and so I KNOW therefore that I got 45 mpg for the first 22 miles of the tank, before the dyno tune.

So, basically that 22 miles used 0.5 gallon, so the remaining 117-22 = 95 miles that consisted of 46 miles of dyno tune plus 49 miles towards home, consumed 3.75 gallons, or 25.3 mpg!

But, how did Mike’s tune affect the ongoing “normal” fuel mileage? Well, after that first fill-up on the way home, I have only had to fill the bike once more, but that fill-up yielded 43.7 mpg. Not much of a difference, and in fact within the “variance rnage” for normal fill-ups. But I’ll need to see what the longer term average is before I can answer the question confidently.

For those wondering why fuel mileage did not plummet to match the 13.0 versus 14.7 AFR tuning targets, i.e. why didn’t it drop to 13.0/14.7 = 88.4% of previous mpg, or .884 x 45 = 39.8 mpg, the answer is simple. By tuning for a more effective AFR, Mike got more power out of each gallon of fuel. i.e. the engine runs more efficiently at AFR of 13.0 versus 14.7.

My overall conclusion about this tuning experience: Mike’s years of experience has really manifested on my bike. The bike is without exaggeration, transformed. If you have not yet had your bike hand tuned, don’t wait any longer. It’s very much worth doing.

Jim G

https://www.hdforums.com/forum/engin...questions.html

At the end of that posting thread, I had told readers I was trying to arrange for Mike Lozano, of Lozano Brothers fame, to tune my bike on his Dynojet, after he dynoed it for me during one of his shop’s monthly “dyno days”, and told me what he suspected was going on with both the shape and absolute numbers on my torque and power curves. But because of the Lozano Brothers’ great reputation, I had to wait 5 or 6 weeks for a spot to clear on Mike’s calendar. He got me in last Friday after returning from a multi-day trip to Atlanta during which he installed and tuned his shop’s unique dragracing clutch on a number of competitive dragracing machines for riders in that area.

Before he started the actual tune, Mike explained to me, first, why the absolute numbers on my bike’s torque and power were lower than I had expected after looking at HD’s Screamin’ Eagle catalog dyno chart for the Stage 4 Race kit.

First, he said, the Softail balancing assembly adds a tremendous amount of rotational inertia, which really hurts the bike on a “sweep” dyno run like the Dynojet dynoing process calls for, as it forces the engine to accelerate the entire drivetrain very rapidly, and the quicker the bike accelerates the drum, the more of its engine power is being diverted to also spin up the balancer assembly (which the unbalanced engines do not have). This is why tuners do the dyno runs on modern Harleys, balanced or unbalanced engines, in 5th gear versus 4th. In 4th gear, the bike can accelerate the drum more rapidly, which also forces the engine to accelerate its internal and drivetrain rotating parts faster, diverting more of the power to spinning up the drivetrain versus spinning up the drum. You can verify this by having your local tuner dynop your bike in 4th and then 5th. The 4th gear run will show lower power and torque.

Then Mike said that the really heavy HD Chrome Turbine rear wheel on my bike adds a tremendous amount of rotational inertia itself in addition, and I realized later back at home, it’s worse than the balancer, because although the engine balancer spins at crank rpm while the rear wheel spins at 1 / (2.78*1.19) = 30% of the engine crank’s rpm, the wheel diameter is several time larger than that of the balancer assembly, so the inertia effect is fairly large. (There is in fact a complex formula that allows you to calculate the inertia that the engine “sees’ for a wheel through a drivetrain, but that’s just plain masochistic to try to actually use – trust me, I’ve tried it in the past).

Mike told me that his past experience suggests that with my Softail balanced engine and that rear wheel, my reported power is going to run “at least” 6 to 8 rwhp lower than for a bike with an “A” (not internally balanced) engine and a more normal rear wheel. Applying that “penalty” to my last dyno chart makes the 104.4 rwhp that was reported on the dyno seem more understandable (104.4 + 6 to 8 rwhp = 110.4 to 112.4 rwhp on an A engine bike with normal wheel).

To really make the point about rotational inertia, Mike told me a story about a high power dragster bike that he and a friend had worked on. On that bike, the experimental substitution of a lightweight drive chain versus the "normal" (for that bike only!!) TRIPLE-plate chain, was enough to cause the bike to lose traction uncontrollably on launch because of the lower inertia of the lightweight chain!

Thinking about that further, I realized it is important to note that at low engine rpm, the 6 to 8% lower power numbers for a Softail with heavy rear wheel translate to torque numbers that are going to be notably lower than for an A engine. This is because the formula for torque is:

Torque = Power x 5252 / rpm

so at low rpm, where rpm is much smaller than 5252 – about half of 5252 – torque overwhelms power in the formula, so any absolute number difference in power in a Softail with heavy wheel is going to be accentuated in low rpm torque numbers. Ie. If the power loss is 6 to 8% at 6000 rpm, the loss in torque at low rpm is going to be several, not just a couple of, foot pounds.

Then, Mike talked about the shape of the torque (and therefore power) curve. He explained that the HD 259E camshafts in my bike have a very long intake duration that promotes high rpm filling of the cylinders, but in his experienced opinion, that cam keeps the intake open TOO long so that at lower engine rpm, the torque and therefore power fall off too much too fast compared to other cams whose duration is less extreme. He really prefers cams with about 4 degrees less duration for these engines.

He also noted that the 58mm throttle body is unnecessarily large for this engine and cam, and adversely hurts incoming charge velocity at high rpm (thus decreasing its momentum) and it really causes issues at low rpm where the volume of air is much lower to begin with. Mike says a 50mm throttle body would have been a better choice for HD to make for the Stage 4 kit.

Mike told me he was not at all surprised by the numbers my bike posted – they are pretty much exactly what he expects to see, and what he HAS seen on other Softails, but exaggerated further because of that heavy rear wheel.

Overall, Mike had no concerns about the peak power being off in any way. But he was very unhappy with the fall-off of the torque (and therefore also power) curve at 3500 rpm and below, even though he understood its cause (the 259E cam holding the intake open TOO long). He really wanted to focus on that, since a rider spends so much time in the 2000 to 3000 rpm range on the street, even though I knew I was buying a kit with a “high rpm” cam. He simply figured it would make the bike even better for me.

And, I believe Mike when he tells me all this, as he and his brothers have been building and tuning high performance car AND motorcycle engines for over 40 years, and their vehicles tend to WIN. For just ONE example of his engine building and tuning prowess, his own version of a Porsche V8 engine competed with and beat the Porsche factory sponsored engine in a Rolex race. If you want more on his credentials, Google “Lozano Brothers”, and check out what he and his brothers have done in both motorcycle and car racing, both personally and as retained engine and head suppliers to others. Mike has personally built and run dragbikes that ran in the 6s. Oh, and by the way, Mike recently took up a new hobby now that he “is a bit older” (he’s 63); he took up roadracing!

Once he had explained this all to me, Mike started the dyno tune:

I had bought a Power Vision PV-2 tuner for the bike, even though I already have an HD Super Tuner Pro, because Mike prefers the Power Vision, and also because I will later need to make a speedometer correction after Mike changes the final drive ratio for me. The Power Vision allows me to make that change by simply changing the Vehicle Speed Sensor factor field in the ECM, rather than buying an aftermarket speedometer correction device, so I save the cost of buying the aftermarket device and get a portion of the PV tuner “paid for” with that saving.

It took Mike over 3 ½ hours to tune my bike. He explained that because each tuner does a tune somewhat differently, starting with someone else’s earlier tune adds time instead of saving it, so he would NOT be starting with the Cowboy HD dealership tune, but rather he was starting with a Power Vision download file for a 110 cubic inch engine with many similarities to my own engine, the 2 into 1 exhaust similarity being an important factor in choosing a starting tune.

I also noticed how much time Mike devoted to the low rpm range and the multiple throttle openings at each rpm, followed by spark advance adjustments. He did the front cylinder first, and then the rear. When I say low rpm, I mean down to just above idle. When I asked why that amount of time at those really low engine rpm points, he explained that this would manifest as greatly improved performance right off a standing start in normal riding, and would also help clean up the nasty cold start problem that had appeared after the HD dealership Stage 4 custom tune (see later in this posting).

I noticed too that Mike, while very thorough, was also very efficient. He put on only a total of 46 odometer miles in the 3 ½ hours of dyno tuning. But because he knows what he is doing, I could visually SEE in the software display the perfect results he was getting at each and every combination of rpm point and throttle % open point.

Here is a printout of his tuning results, which compares the original Cowboy dealership tune as captured by a dyno run on the Lozano Dynojet prior to Mike retuning the engine, compared to the results of Mike’s tune (on the same Lozano dynojet obviously):

Note first the virtually perfect “tabletop flat” torque curve in the 3500 to 5300 rpm range. This shape of curve is the ideal that every engine builder shoots for in an engine for a road bike that has to have more working range than a drag bike or road race bike, and that should not manifest sudden torque/power changes which can upset traction or front/rear weight distribution in cornering or on slippery road surfaces.

But there’s way more to notice here.

Here is a comparison graph that shows very clearly:

• The results of the Cowboy HD dealership tune as shown on the dealership Dynojet, using the dealership dyno technique

• The results of the Cowboy HD dealership tune as shown on the Lozano Dynojet (SAME tune, just dynoed on the Lozano dyno using Mike’s dyno technique vs dynoed on the Cowboy Dynojet using the dealership technique)

• The results of Mike’s tune on the Lozano dyno

The color coding got really badly screwed up by the process of converting my Mac Excel graph into a scrrenshot, and then via iPhoto into a jpg image, and then an upload into Photobucket, but here’s the easy way to know the difference between the 3 sets of lines:

The lowest line, whether power or torque, is always “blue” and is the Cowboy HD dealership tune result.

The middle line, always “red”, is the Cowboy tune properly dyoned on the Lozano Dynojet.

The top line is always the Lozano tune. The Brown curve is the Lozano torque curve. The Black curve is the Lozano power curve.

The orange curve near the bottom of the graph is the increase in torque that Mike Lozano got versus the Cowboy tune. (And, this is measured against the Cowboy tune as accurately reported on the Lozano dyno, not as defectively reported on the Cowboy dyno – see the discussion below to understand this.)

Here is the numerical data table for the above graph:

There are some very interesting attributes and facts within this table: