103-113": Tryin to decide why the big dip in low end ?

#22

#23

Yes indeed!! Those in this thread claiming pipes dont effect low end with 57's just got skooled.

First sheet with 57's and a "stock" header hits 100 tq @ 2600 rpms. Darens/Durwood sheet with 57s and a header and mellows hits 100 tq @ 2400 rpms.

.

First sheet with 57's and a "stock" header hits 100 tq @ 2600 rpms. Darens/Durwood sheet with 57s and a header and mellows hits 100 tq @ 2400 rpms.

.

#25

#26

Clayton, if Durwood is within a ride from you, consider him to tune your bike. His info is on the Sheffer dyno sheet I posted. He is a very respected tuner and always very helpful.

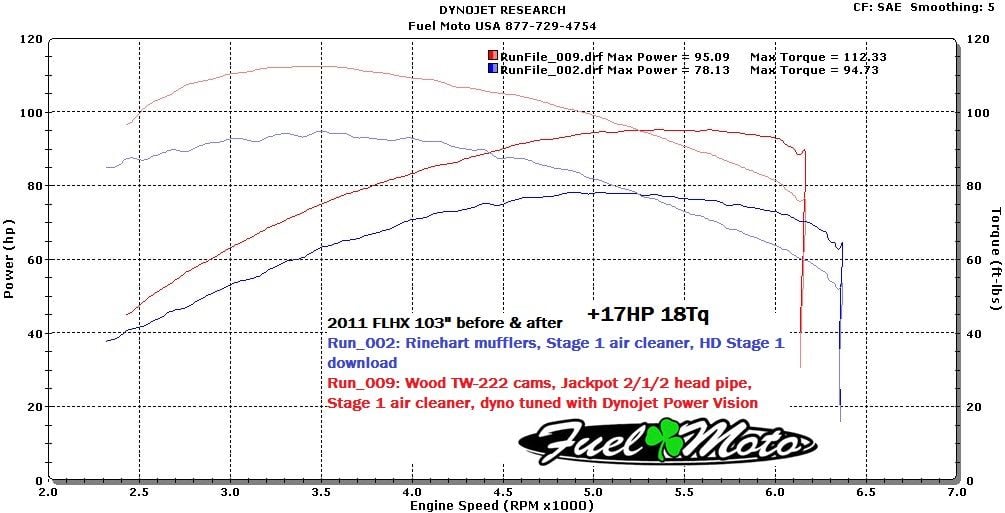

Its interesting you say that. What is the proper compression? Here are tw222's in a 103 WITH a FM header. The curve is very very close to 57's with a stock header. Room for growth? Sounds good

.

.

#27

You can take the 222's up to 10.1 if you want and that would put your CCP to 199 psi. Which is pushing it for that cam and might make it a little more difficult to tune. I would think that 9.8-9.9 static with ccp @191/194 would be optimal for the street. A little less heat and a little more timing could make all the difference.

#28

I haven't played around with the 57 to find it. Generically? A 57 bolt in on stock will be about 9.17 corrected. Set static up around 10.2 and you are 9.48 corrected. Tq would come up in lower rpm and if headwork was done to support. TQ would carry out better which would turn into an increase in HP also.

I don't disagree with you or others that the crushers will help with this. Plenty of poor pipe choices have came through here. Shoving something in the pipe and having it held there for a pull or two will prove you guys correct. Same can be said with bending TH baffles. BUT there is a point when a smaller baffle is going to hurt top end. Wider margin of error here when dealing with a cam that would be a bell ringer at 115hp in a 103.

Compared to something like this. Where a dip down low is tolerable because to install something that would raise pressure in the pipe at a lower rpm with create to much pressure at top end and hurt output. IMO if you could create a pipe and baffle that could hold an average of 2 psi through out entire RPM band. Would be good, and I think that is the theory behind spiral core louver baffles.

https://www.hdforums.com/forum/dyno-...-b2-heads.html

I brought it up solely for conversation. Don't mean to hijack Clayton. I also agree that Sheffer's would be a great place for you. Along with getting a tune on a bike. The better ones will play around a bit so they can point you in the right direction if needed.

#29

If I read correctly, the are two different cams used in this comparison 57's vs 570. The 570 cam is designed to come in sooner and is using different pipes and slip ons than the 57's so I wouldn't think this is a legitimate comparison...

You can take the 222's up to 10.1 if you want and that would put your CCP to 199 psi. Which is pushing it for that cam and might make it a little more difficult to tune. I would think that 9.8-9.9 static with ccp @191/194 would be optimal for the street. A little less heat and a little more timing could make all the difference.

You can take the 222's up to 10.1 if you want and that would put your CCP to 199 psi. Which is pushing it for that cam and might make it a little more difficult to tune. I would think that 9.8-9.9 static with ccp @191/194 would be optimal for the street. A little less heat and a little more timing could make all the difference.

The point was the tw222 has a FM header - a $600 investment increase yet results are practically the same as 57's with stock header. Some say the 57's need more compression to work in a 103". And your comment seemed to elude to that, "I wonder what proper compression for the cam and correct exhaust would do?".

#30

I haven't played around with the 57 to find it. Generically? A 57 bolt in on stock will be about 9.17 corrected. Set static up around 10.2 and you are 9.48 corrected. Tq would come up in lower rpm and if headwork was done to support. TQ would carry out better which would turn into an increase in HP also.

I don't disagree with you or others that the crushers will help with this. Plenty of poor pipe choices have came through here. Shoving something in the pipe and having it held there for a pull or two will prove you guys correct. Same can be said with bending TH baffles. BUT there is a point when a smaller baffle is going to hurt top end. Wider margin of error here when dealing with a cam that would be a bell ringer at 115hp in a 103.

Compared to something like this. Where a dip down low is tolerable because to install something that would raise pressure in the pipe at a lower rpm with create to much pressure at top end and hurt output. IMO if you could create a pipe and baffle that could hold an average of 2 psi through out entire RPM band. Would be good, and I think that is the theory behind spiral core louver baffles.

https://www.hdforums.com/forum/dyno-...-b2-heads.html

I brought it up solely for conversation. Don't mean to hijack Clayton. I also agree that Sheffer's would be a great place for you. Along with getting a tune on a bike. The better ones will play around a bit so they can point you in the right direction if needed.

I don't disagree with you or others that the crushers will help with this. Plenty of poor pipe choices have came through here. Shoving something in the pipe and having it held there for a pull or two will prove you guys correct. Same can be said with bending TH baffles. BUT there is a point when a smaller baffle is going to hurt top end. Wider margin of error here when dealing with a cam that would be a bell ringer at 115hp in a 103.

Compared to something like this. Where a dip down low is tolerable because to install something that would raise pressure in the pipe at a lower rpm with create to much pressure at top end and hurt output. IMO if you could create a pipe and baffle that could hold an average of 2 psi through out entire RPM band. Would be good, and I think that is the theory behind spiral core louver baffles.

https://www.hdforums.com/forum/dyno-...-b2-heads.html

I brought it up solely for conversation. Don't mean to hijack Clayton. I also agree that Sheffer's would be a great place for you. Along with getting a tune on a bike. The better ones will play around a bit so they can point you in the right direction if needed.

Fullsac 1.75" in a M8 120" build. In a 103~110, low end bump with no concerns of flow restriction. The 120 gave up a bit on the right compared to 2", but according to FS Steve the gains on the left and mid outweighed that. Which relates to your point, although for a large build.

------------------------------------

Here's one anybody can build with basic mechanical skills. The only internal changes were a bolt on piston kit, Cam and valve spring kit.

Started with a stock 107 that made 75 Hp and ended at well over 120 HP with stock heads and TB. Excellent low end power, 110 FT pounds at the hit!

And a quiet set of 1.75 baffles.

Bike- 2017 107 M8 Road Glide Special. Black of course.

Parts list

120 M8 piston kit, purchased from Suburban Speed.

CVO 114 barrels, purchased used from CVO member then bored to 4.185

No case boring, all bolt on.

TTS 200 cam

SE valve spring kit

SE 5.5 injectors

Fullsac MX Pipe

Fullsac 1.75 baffles in modded 107 mufflers

SE Heavy Breather

TTS Tuner

Stock heads and throttle body!

Never ride with a Halfsac! Insist on Fullsac Performance!

Steve@fullsac.com

Thread

Thread Starter

Forum

Replies

Last Post