Winter Project : ElectraGlide Swingarm, Top End and Bags

#141

Join Date: Jan 2011

Location: Haslet Texas

Posts: 20,999

Likes: 0

Received 4,317 Likes

on

1,946 Posts

On the question of replacing the studs, my thoughts are this: The great advancement for HD with the Evo engine was going to the "through" cylinder stud design. The old style mini-studs (from the Shovel on back) allowed very little stretch because they were so short. The Evo's through studs allow lots more stretch with allows more consistent pressure.

Evo cylinder studs live inside the elastic range of the Grade 9 steel the studs are made from. Cold tension on the studs is about 5,000 pounds. The tension on the studs at operating temperature (the stack grows about 18 thou when it comes up to temp) is about 7,000 pounds. With 3/8" dia studs, that works out to about 64kPSI of tension, which is way below the yield strength of the steel. By staying inside the elastic range of the steel, there is no permanent deformation of the studs, which makes sense. They would pull out of the relatively soft alloy case before they got anywhere near breaking (or even permanently deforming) under tension.

On the question of installing them shoulder end up v. shoulder end down, its just my natural OCD that tells me to put them in shoulder up. Otherwise, I'd end up with five studs (the ones that didn't come out) shoulder up, and three down. That would bug me forever.

Evo cylinder studs live inside the elastic range of the Grade 9 steel the studs are made from. Cold tension on the studs is about 5,000 pounds. The tension on the studs at operating temperature (the stack grows about 18 thou when it comes up to temp) is about 7,000 pounds. With 3/8" dia studs, that works out to about 64kPSI of tension, which is way below the yield strength of the steel. By staying inside the elastic range of the steel, there is no permanent deformation of the studs, which makes sense. They would pull out of the relatively soft alloy case before they got anywhere near breaking (or even permanently deforming) under tension.

On the question of installing them shoulder end up v. shoulder end down, its just my natural OCD that tells me to put them in shoulder up. Otherwise, I'd end up with five studs (the ones that didn't come out) shoulder up, and three down. That would bug me forever.

There's nothing worse than assembling something and having a bug in your ear telling you something ain't right.

You'd never trust that motor or whatever you assembled to last and therefor you'd quit using it as unreliable.

#142

On the question of replacing the studs, my thoughts are this: The great advancement for HD with the Evo engine was going to the "through" cylinder stud design. The old style mini-studs (from the Shovel on back) allowed very little stretch because they were so short. The Evo's through studs allow lots more stretch with allows more consistent pressure.

Evo cylinder studs live inside the elastic range of the Grade 9 steel the studs are made from. Cold tension on the studs is about 5,000 pounds. The tension on the studs at operating temperature (the stack grows about 18 thou when it comes up to temp) is about 7,000 pounds. With 3/8" dia studs, that works out to about 64kPSI of tension, which is way below the yield strength of the steel. By staying inside the elastic range of the steel, there is no permanent deformation of the studs, which makes sense. They would pull out of the relatively soft alloy case before they got anywhere near breaking (or even permanently deforming) under tension.

On the question of installing them shoulder end up v. shoulder end down, its just my natural OCD that tells me to put them in shoulder up. Otherwise, I'd end up with five studs (the ones that didn't come out) shoulder up, and three down. That would bug me forever.

Evo cylinder studs live inside the elastic range of the Grade 9 steel the studs are made from. Cold tension on the studs is about 5,000 pounds. The tension on the studs at operating temperature (the stack grows about 18 thou when it comes up to temp) is about 7,000 pounds. With 3/8" dia studs, that works out to about 64kPSI of tension, which is way below the yield strength of the steel. By staying inside the elastic range of the steel, there is no permanent deformation of the studs, which makes sense. They would pull out of the relatively soft alloy case before they got anywhere near breaking (or even permanently deforming) under tension.

On the question of installing them shoulder end up v. shoulder end down, its just my natural OCD that tells me to put them in shoulder up. Otherwise, I'd end up with five studs (the ones that didn't come out) shoulder up, and three down. That would bug me forever.

Studs in my world are prone to breakage. (as stated above)

This is a forum and ya gets what ya gets from the populace at large.

I may be wrong for your way of thinking, it is all ok and is good for discussion if nothing else.

I for my part just replace them as a matter of course.

Like I said it is cheap insurance.

Plus I have a very moded engine which is trying to send the top end top the moon with every other stroke.

#143

#145

#146

...

On the question of installing them shoulder end up v. shoulder end down, its just my natural OCD that tells me to put them in shoulder up. Otherwise, I'd end up with five studs (the ones that didn't come out) shoulder up, and three down. That would bug me forever. :icon_screwy:

On the question of installing them shoulder end up v. shoulder end down, its just my natural OCD that tells me to put them in shoulder up. Otherwise, I'd end up with five studs (the ones that didn't come out) shoulder up, and three down. That would bug me forever. :icon_screwy:

.

Last edited by multihdrdr; 01-04-2019 at 08:22 PM.

#147

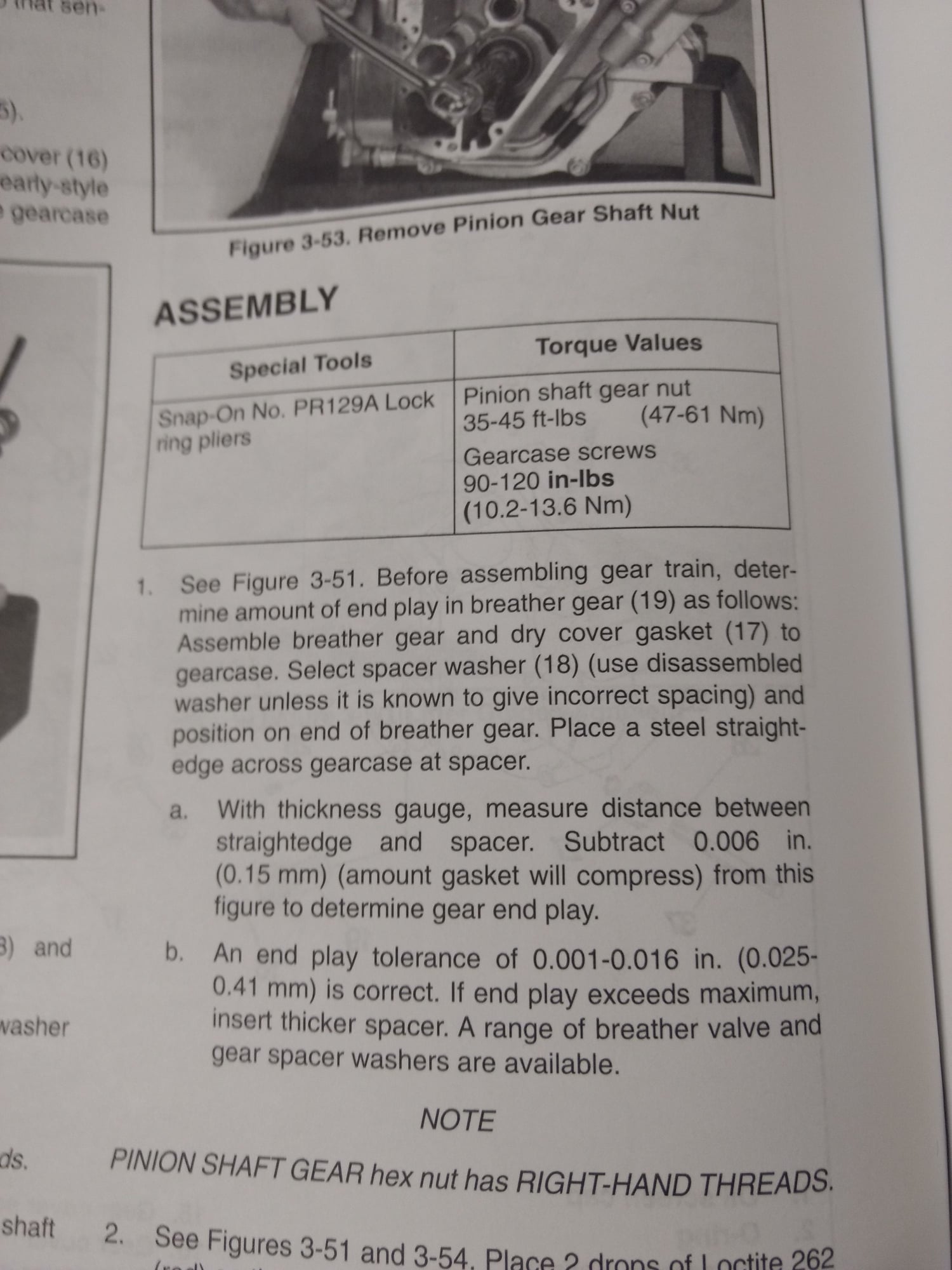

Got some headway tonight. Studs are in. Got the cam and the breather in and was ready to test the cam endplay when I discovered that my Cometic gasket kit doesn't include the one for the cam chest. Oops. Stuck for now. Hopefully my dealer can hook me up tomorrow.

Here's a question: The S&S breather came with a selection of variable width shims. How does a guy go about figuring which one to use?

#148

#149

#150

The following users liked this post:

Kingglide549 (01-05-2019)