2003 road king compensator nut 5,500k

#1

My 2003 road king with 5,500 miles compensator nut coming off. Harley says 75 foot pounds of torque then 45 degrees from there. I checked with torque wrench and ended up with 235 foot pounds. That is a lot more than the factory 165 max. I still think I should have ran my marks clear over to the inter primary. I am not positive that the compensator might have moved. Anyone else ever check their torque after this new method of tightening? That is a lot of torque on that spindle nut and crankshaft!

#2

My 2003 road king with 5,500 miles compensator nut coming off. Harley says 75 foot pounds of torque then 45 degrees from there. I checked with torque wrench and ended up with 235 foot pounds. That is a lot more than the factory 165 max. I still think I should have ran my marks clear over to the inter primary. I am not positive that the compensator might have moved. Anyone else ever check their torque after this new method of tightening? That is a lot of torque on that spindle nut and crankshaft!

#7

The C/N on my 01 E Glide came loose just before I bought it. Had about 40K miles on it. I did some diggin and found a TSB that in essence puts the nut at 240ish ftlbs when you follow the HD procedure. If I recall the original spec was 175 ftlbs not 75 as mentioned before the additional turn.

Trending Topics

#8

#9

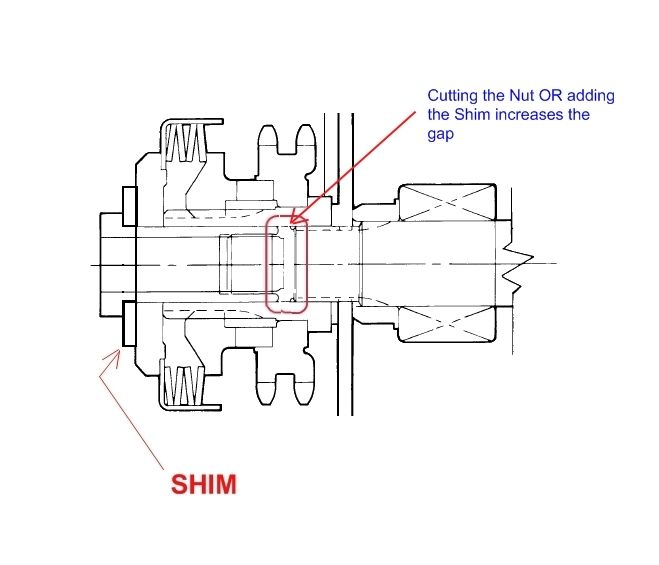

I stand corrected on the 45* procedure for 2993-2005 models. Have had the comp nut on and off my 2002 FLHT many times, torqued to 165 ft.lb per manual, hipo engine, ridden hard and it has never come loose. However, the nut has been shortened by .030".

I would bet a six pack that if you shave the comp nut and torque to 175 ft.lb. with a drop or two of red, it will not come loose.

I would bet a six pack that if you shave the comp nut and torque to 175 ft.lb. with a drop or two of red, it will not come loose.

#10

djl. Good Call! This winter I will prolly tear into it again and keep the washer on the spindle nut and tighten it to 175. Now it is at 235lbs makes me nervous, in fear of stripping the threads off! I already bought another new spindle nut with the patch, I will add 3 drops of red locktight to it also. $10.00 from Harley gets you a new spindle nut. Bought a primary gasket today cost $30.00, I thought it should be the other way around. Thanks for the post.