Knocking 2100-2400 RPM

#1

Hey Folks

I have a 2000 Electra Glide that I just purchased used. It has a 96" kit installed along with the upgraded cam chain and oil pump kit.

I have a knocking noise that only comes under load between 2100- 2400 rpm. It is hard to tell if it is top or bottom end but I think it is lower on the clutch side.

Any info or person experience would be helpful..

Thanks

I have a 2000 Electra Glide that I just purchased used. It has a 96" kit installed along with the upgraded cam chain and oil pump kit.

I have a knocking noise that only comes under load between 2100- 2400 rpm. It is hard to tell if it is top or bottom end but I think it is lower on the clutch side.

Any info or person experience would be helpful..

Thanks

#2

#3

#6

Generally, when a torque to angle spec is given, that angle from a specific pre-set torque value is the one that has been shown to provide the proper clamp load for the assy in question. The method for obtaining that angle value is somewhat beyond the scope of this forum, but a google search for "torque to angle", "torque to yield", etc. should prove interesting for those so inclined to investigate further.

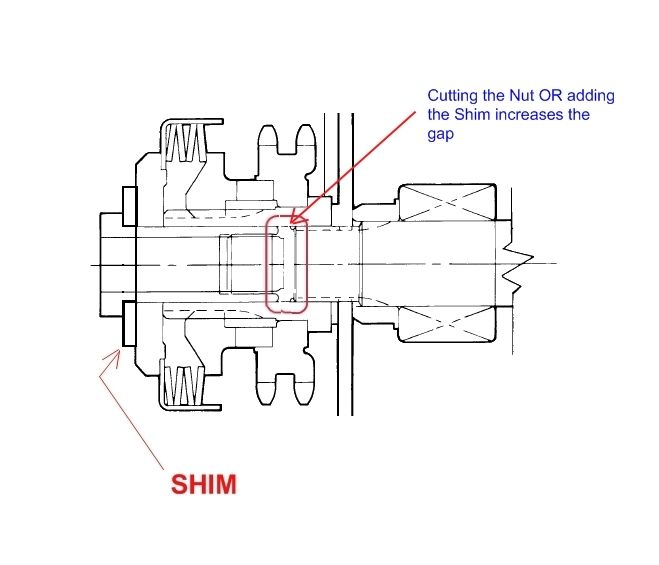

AFAIK, pre '03 (tapered roller main roller bearing) have a torque spec of 150-165 ft/lbs and the '03 and later motors use the torque to value then to the specified angle. IIRC, that would be 150ft/lb plus another 1/4 turn. As previously posted, trimming the compensator nut ~0.030 or using a shim under the nut are commonly done to solve any stackup issues. You may want to check out HD bulletin M-1170 ...and I strongly recommend the H-D service manual.

AFAIK, pre '03 (tapered roller main roller bearing) have a torque spec of 150-165 ft/lbs and the '03 and later motors use the torque to value then to the specified angle. IIRC, that would be 150ft/lb plus another 1/4 turn. As previously posted, trimming the compensator nut ~0.030 or using a shim under the nut are commonly done to solve any stackup issues. You may want to check out HD bulletin M-1170 ...and I strongly recommend the H-D service manual.

#7

Trending Topics

#9

Is the bike injected or carburated? Is the cam plate the S/E hybrid or a complete conversion to roller chains? Injected bikes with the M/M system are noisey when the stock air box is replaced with an open breather system.

I have a 2000 injected bike and had the same rpm range noise that you have. Converted to roller chains and put the stock air box back on to surpress the sound coming out the throttle body.

I have a 2000 injected bike and had the same rpm range noise that you have. Converted to roller chains and put the stock air box back on to surpress the sound coming out the throttle body.

Thread

Thread Starter

Forum

Replies

Last Post

waikiki

Primary/Transmission/Driveline/Clutch

8

05-31-2012 09:22 AM

txphatboy

General Harley Davidson Chat

16

08-28-2011 09:38 AM