Messed up my cam install!!! <smdh>

#31

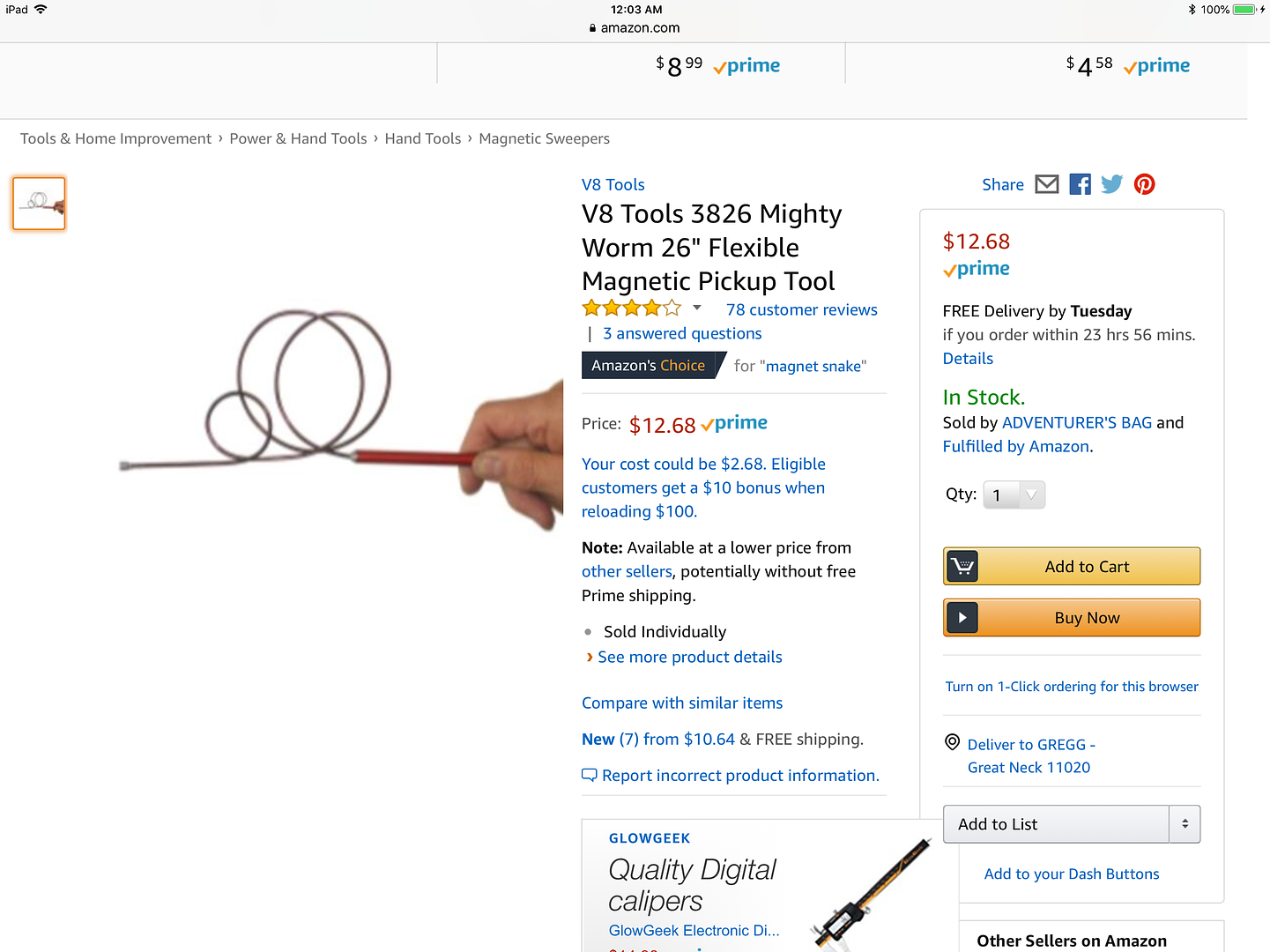

What is the tip diameter of that magnet? I have not seen one so small before. That might be worth a shot if it fits. The struggle here is that the amount of space between the cam bearing journal and the flywheel is much smaller than I think people realize. I would estimate 1/8 - 3/16" between them to fish though, which would be tough on its own.... let alone being shrouded by the depth of the 1.25" bearing journal.

I have the rest of the bearing sitting on the shelf, so its easy for me to inventory what is missing... its definitely just 2 rollers and one sliver of cage, although that sliver may have cracked into a couple small pieces (i have no way to know if the sliver stayed intact).

I have the rest of the bearing sitting on the shelf, so its easy for me to inventory what is missing... its definitely just 2 rollers and one sliver of cage, although that sliver may have cracked into a couple small pieces (i have no way to know if the sliver stayed intact).

The following users liked this post:

phunk (08-18-2018)

#32

I mean, I obviously have a very biased point of view at the moment... But I am starting to get a little frustrated by the fact that someone is actually mass producing an engine that has no drain plug on the crank case. I cant really think of a universe where that sounds like a great idea. I may be the first guy that runs into this as a big dilemma, and it may be at 100% my own fault... but I am not the last person who is going to run into this. Some day in the not too distant future, a HD service tech is going to drop something down there when the jugs are out, and have to pull the entire damn thing apart to retrieve it.

If I actually have to split this case open to get that crap out of here, just for my own damn satisfaction, I am going to drill a big *** hole and weld a -10 ORB port to the bottom of that sump. And not going to lie, a piece of me is considering that as an immediate option.

If I actually have to split this case open to get that crap out of here, just for my own damn satisfaction, I am going to drill a big *** hole and weld a -10 ORB port to the bottom of that sump. And not going to lie, a piece of me is considering that as an immediate option.

Last edited by phunk; 08-18-2018 at 11:20 PM.

The following users liked this post:

Zedbra (08-19-2018)

#33

#34

I removed the NPT plug on the bottom of the right case that Steve Cole mentioned. A little more oil did come out, but no bearings. When followed straight up, this channel leads directly to the inner oil pump gearotor scavenge. So it must T off to the crank case sump somewhere between (I wont be able to see until better light tomorrow). How likely I will be able to get anything out this hole probably depends on how many turns there are between that vertical channel and the crankcase sump.

Perhaps tomorrow I will try pouring a quart of oil into the crankcase via the cam bearing journal and see if these bits come out that NPT hole.

Is anyone here intimately familiar with the lubrication system on the M8? I am trying to gather the function of each pump stage. Does the inner stage scavenge the crankcase and send to the tank, and the outer stage scavenge the tank and create the oil pressure for the engine? I think I now gather that the crankcase is not connected at all to where the oil is stored, so attempting to drain oil out the standard oil drain plug is not going to accomplish anything at all. I now believe that nothing leaves the crankcase without first traveling the inner oil pump stage.

Is anyone here intimately familiar with the lubrication system on the M8? I am trying to gather the function of each pump stage. Does the inner stage scavenge the crankcase and send to the tank, and the outer stage scavenge the tank and create the oil pressure for the engine? I think I now gather that the crankcase is not connected at all to where the oil is stored, so attempting to drain oil out the standard oil drain plug is not going to accomplish anything at all. I now believe that nothing leaves the crankcase without first traveling the inner oil pump stage.

Harleyís are a dry sump motor so the oil reservoir is separate. The oil is scavenged from the crankcase and pumped to the reservoir.

I mean, I obviously have a very biased point of view at the moment... But I am starting to get a little frustrated by the fact that someone is actually mass producing an engine that has no drain plug on the crank case. I cant really think of a universe where that sounds like a great idea. I may be the first guy that runs into this as a big dilemma, and it may be at 100% my own fault... but I am not the last person who is going to run into this. Some day in the not too distant future, a HD service tech is going to drop something down there when the jugs are out, and have to pull the entire damn thing apart to retrieve it.

If I actually have to split this case open to get that crap out of here, just for my own damn satisfaction, I am going to drill a big *** hole and weld a -10 ORB port to the bottom of that sump. And not going to lie, a piece of me is considering that as an immediate option.

#35

ive found that it does get to the sump, but with at least 1 turn, perhaps more (no way for me to know without a spare case to examine). When followed straight up, it goes to the oil pump scavenge directly behind the oring seal interface. Iím hoping it just has the 1 T intersection turn to get to the sump, which is possible because I donít see any obvious channels in the casting visible from exterior or photo of interior of the case. If itís just that simple, I just might get this crap out of there yet by flushing it into the bottom of the sump. Iíll need to figure out a way to lean the bike hard right to attempt and pour the sump contents out the right side of the case.

Pipe threads in cast aluminum is always a concern, especially when itís very thin like around this plug. The tapered diameter will crack that sucker wide open if you thread too deep. Thatís one warning I didnít need, seen that happen plenty. Their too cheap to use a port reamer so they give us pipe threads... which I hate, in every application

#36

Join Date: Jul 2012

Location: Cranbourne, VIC Australia

Posts: 1,996

Received 416 Likes

on

311 Posts

i havenít found photos of the interior of the left case half to know better... if I pour a lot of something into the crankcase, are there any channels that could allow it to make its way into the primary or trans? Iím not excited about contaminating the entire drivetrain with fluids like that. Iím assuming it would definitely run into the primary if I pour in fast enough for fluid level to reach the crank bearing. So I should try and take it easy not to just flood the case.

The following users liked this post:

phunk (08-19-2018)

#37

The engine oil and trans or primary will not mix regardless of how much mineral spirits/alcohol/diesel you poor in the engine, they are completely sealed from each other. The primary is connected to the trans for venting purposes, but the engine is vented separately thru the intake so you don't have to worry.

#38

Join Date: Jul 2012

Location: Cranbourne, VIC Australia

Posts: 1,996

Received 416 Likes

on

311 Posts

No worries bud. Remember you can see thru the right side crank bearing because it is not sealed as the cam chest is oiled by the same oiling system as the rest of the engine. The left side is sealed, because the primary case has its own oiling system for the primary and clutch.

#39

Very nice of all these top forum experts to offer their valuable advice and expertise for free,they seem to have covered every option.They have all this experience because even some of then have failed with this delicate install.

There are hundreds of thousands of old Twin Cams running with the original specified and currently used and more expensive caged type bearing.Even on major top end rebuilds,we leave it alone!

The only exception is on stage 111 and 1V where special valve springs are required for the HIGH LIFT,higher load Cams.

Harley Davidson only supply the full compliment roller bearing together with the conical high lift springs on the High Compression High Lift cam sets! On these sets removal of the rockers,heads,and replacement of the Pistons and sleeves is mandatory.

In this case we exchange the cam bearing whilst the cylinders are off.This allows improved access and visual confirmation of what you may be screwing up.

I say again the mild and changed duration Stage 11 cams do not increase the bearing load so leave them alone to ensure you are not riding a better performing,time BOMB!

The inspection cameras are the best visual confirmation of location with magnet retrieval.

If this fails take the pain,pull the cylinders and pistons and don't stop till you have all the pieces in your hand! Sorry.

There are hundreds of thousands of old Twin Cams running with the original specified and currently used and more expensive caged type bearing.Even on major top end rebuilds,we leave it alone!

The only exception is on stage 111 and 1V where special valve springs are required for the HIGH LIFT,higher load Cams.

Harley Davidson only supply the full compliment roller bearing together with the conical high lift springs on the High Compression High Lift cam sets! On these sets removal of the rockers,heads,and replacement of the Pistons and sleeves is mandatory.

In this case we exchange the cam bearing whilst the cylinders are off.This allows improved access and visual confirmation of what you may be screwing up.

I say again the mild and changed duration Stage 11 cams do not increase the bearing load so leave them alone to ensure you are not riding a better performing,time BOMB!

The inspection cameras are the best visual confirmation of location with magnet retrieval.

If this fails take the pain,pull the cylinders and pistons and don't stop till you have all the pieces in your hand! Sorry.

The following users liked this post:

phunk (08-21-2018)

#40

Join Date: Jul 2012

Location: Cranbourne, VIC Australia

Posts: 1,996

Received 416 Likes

on

311 Posts

Very nice of all these top forum experts to offer their valuable advice and expertise for free,they seem to have covered every option.They have all this experience because even some of then have failed with this delicate install.

There are hundreds of thousands of old Twin Cams running with the original specified and currently used and more expensive caged type bearing.Even on major top end rebuilds,we leave it alone!

The only exception is on stage 111 and 1V where special valve springs are required for the HIGH LIFT,higher load Cams.

Harley Davidson only supply the full compliment roller bearing together with the conical high lift springs on the High Compression High Lift cam sets! On these sets removal of the rockers,heads,and replacement of the Pistons and sleeves is mandatory.

In this case we exchange the cam bearing whilst the cylinders are off.This allows improved access and visual confirmation of what you may be screwing up.

I say again the mild and changed duration Stage 11 cams do not increase the bearing load so leave them alone to ensure you are not riding a better performing,time BOMB!

The inspection cameras are the best visual confirmation of location with magnet retrieval.

If this fails take the pain,pull the cylinders and pistons and don't stop till you have all the pieces in your hand! Sorry.

There are hundreds of thousands of old Twin Cams running with the original specified and currently used and more expensive caged type bearing.Even on major top end rebuilds,we leave it alone!

The only exception is on stage 111 and 1V where special valve springs are required for the HIGH LIFT,higher load Cams.

Harley Davidson only supply the full compliment roller bearing together with the conical high lift springs on the High Compression High Lift cam sets! On these sets removal of the rockers,heads,and replacement of the Pistons and sleeves is mandatory.

In this case we exchange the cam bearing whilst the cylinders are off.This allows improved access and visual confirmation of what you may be screwing up.

I say again the mild and changed duration Stage 11 cams do not increase the bearing load so leave them alone to ensure you are not riding a better performing,time BOMB!

The inspection cameras are the best visual confirmation of location with magnet retrieval.

If this fails take the pain,pull the cylinders and pistons and don't stop till you have all the pieces in your hand! Sorry.