Harley Davidson Dyna Glide: Engine Noise Diagnostic Guide

The Harley V-twin engine is characteristically noisy. Many owners find themselves fretting over engine sounds that clatter, tick, and rattle, but experience no ride-ability issues or loss of performance. It is a good idea to familiarize yourself with the sounds of your bike, so when a new noise pops up, you can distinguish it from the rest and take appropriate action.

This article applies to Harley Davidson Dyna Glide (2000-2016).

Compared to other motorcycles on the road, Harley Davidson motorcycles have a fairly unique engine design. Harley engines have evolved over the years, but still remain true to their roots with a 45 degree air-cooled pushrod V-twin installed in Dyna models. Air-cooled engines lack water-jackets for cooling, so many noises that would traditionally be muffled are more audible. Additionally, most modern bikes use overhead camshaft setups, which are by design quieter than a pushrod valvetrain. Harley's have a distinctive sound that include many different clicks and clatters. Many owners coming from the world of Japanese or European motorcycles are often taken back by the variety of noises emanating from their engine and begin to worry that a catastrophic engine failure may be on the horizon. Fortunately, most of these noises are the nature of the beast, but knowing what to listen for can go a long way in catching potential problem before it is too late. This article will focus on common engine noises that occur in Harley Dyna Glide models.

Material Needed

- Mechanic's stethoscope

Pinpoint Sound

The first step in diagnosing an engine noise is to narrow down which area the sound is coming from and under which conditions the noise occurs. A mechanic's stethoscope is a great tool to use when diagnosing engine noises, as the probe can reach into tight places to monitor the sounds of the engine. Similarly, placing the end of a long screwdriver or extension against the engine and the other end against your ear can act like a stethoscope, but will be much less precise. When probing for the source of a noise, be aware of the engine temperature as well as the RPM at which the noise typically occurs.

Pro Tip

If is recommended that you probe for various engine noises annually or during each service interval.

Valvetrain Noise

It is important to understand that the valvetrain in Harley engines inherently tick and clatter, even when new. These big V-twin engines have large valves with heavy spring pressure that all add up a degree of noise not found in many modern engines. If you are hearing an engine noise, chances are it is emanating from the valvetrain.

If your are hearing an abnormal clattering or ticking noise, chances are it is a lifter. The twin cam engine uses hydraulic lifters, which are able to compensate for heat expansion and normal valvetrain wear. This lifter setup eliminates the need for traditional valve adjustments; however, the oil in the lifters has been known to leak off, especially in a bike that has been sitting for an extended period of time, making them noisy at startup. The lifters should pump up with oil as oil pressure builds and the noise should go away after the bike has run a bit. If ticking lifters persist at all times, Harley suggest that the oil pressure be checked while the bike is running. Excessively high or excessively low oil pressure has been known to cause lifter problems. Assuming the oil pressure measures within spec, a lifter can become stuck and cause a ticking noise at all times. If this is the case, the lifters need to be inspected and replaced as necessary, as excess valve lash can ruin a motor in a hurry.

Pro Tip

Oil type and viscosity can play a major role in valvetrain noise. A quality oil suited to the environmental conditions in which your bike is operated can greatly reduce the characteristic ticks and clatters.

Top-End (Piston) Noise

Many individuals will experience some form of piston slap in their Harley engines. This noise will often have a low-pitched metal to metal tapping sound as the piston rocks back and forth in the cylinder. Being air-cooled, Harley has engineered the pistons—especially the forged units in newer models—to fit rather loosely in the cylinders when cold to allow for proper expansion and clearances when the engine is at operating temperature. The noise should subside once the engine has warmed-up; however, excessive slap that regularly occurs can be an indication of a high mileage engine that needs a rebuild. A number of engine builders feel that Harley's tolerances are bit lax from the factory, and, in some cases, Dyna owners have had their top-ends replaced under warranty. You can check for recalls and service bulletins using your bike's VIN number.

Bottom-End (Crankshaft) Noise

The crankshaft flywheels in the twin cam engine are pressed together and have the potential to twist or slip, which will cause a knocking noise in the bottom end or near the gear case; plus, a much more noticeable engine vibration. When the crankshaft becomes eccentric and runs out of balance, damage to the cam plate, cam chain tensioners, and main bearings can occur. For newer bikes that have an automatically adjusting primary chain tensioner, this slipped crankshaft has the potential to allow the tensioner to excessively tighten and place an extreme load on the left side main bearing and primary mainshaft, thus leading to premature failures. If you haven't figured it out yet, a twisted or slipped crank is a serious issue. The twisted crankshaft often occurs after engine performance modifications; however, aggressive acceleration, deceleration, and high revving burnouts with stock motors have been known to cause the issue as well. This is perhaps the most costly failure on the twin cam engine, as it can basically trash all engine components, leaving you in need of an entire engine. Prompt action when you first notice the noise or vibration can prevent a catastrophic failure, but you are still looking at an costly bottom-end rebuild.

Cam Chain Tensioners

Often referred to as the 'Achilles Heel' of the Twin Cam engine are the spring loaded cam chain tensioners on pre-2007 models. At one time, Harley had used gear driven cams, but to cut down on noise, reverted to a silent timing chain setup as used in many car engines. The problem with this setup is that the tensioner pads will wear and fail, which not only severely affects timing, but also sends a bunch of hard plastic debris through the engine and cause a host of problems. This wear is not typically heard without the aid of a mechanic's stethoscope, but using one near the cam cover will allow you to audibly distinguish the rattling/skating noise associated with a loose chain and failing tensioner pads.

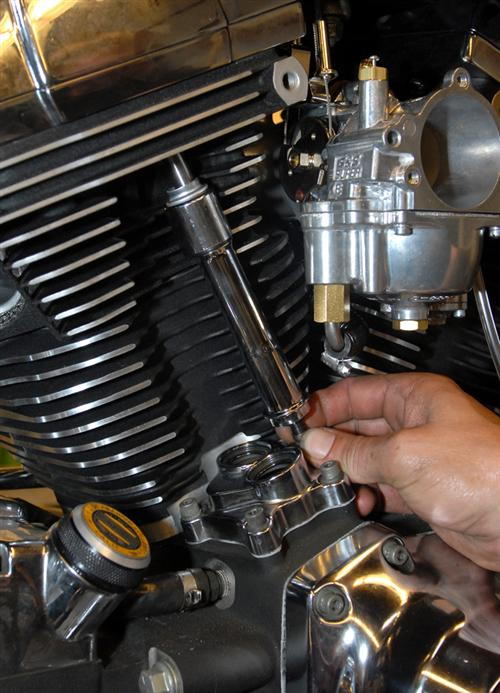

Primary Drive

A distinctive rattling or clattering noise coming from the left side of the motorcycle is likely a problem in the primary drive. A very common problem that owners have experienced is the compensating sprocket nut/bolt backing off and rubbing against the outer primary cover. If left unchecked, the fastener can eat away at the cover and the crankshaft can shift side to side, possibly leading to oil pump failure. A loose compensating sprocket nut/bolt will be most noticeable during On-Off throttle transitions.

Another potential primary issue is the automatically adjusting tensioner used on bike from 2007 onward. The design automatically takes up slack, but it is not spring loaded to compensate for the uneven stretch you sometimes find in chains. A too tight adjuster can sound kind of like the clacka-clacka of a train going down the tracks. Running with a too tight primary chain for too long can lead to premature bearing failure. The aftermarket offers spring loaded automatic adjusters that make up for the Motor Company's poor design.

Related Discussions

- Engine Ticking Noise When Warm - HDForums.com

- Engine Noise Driving Me Crazy! - HDForums.com

- Excessive Valve Noise...Possible Lifters? - HDForums.com