Harley-Davidson's Ultra Modern Pilgrim Road Powertrain Plant (photos)

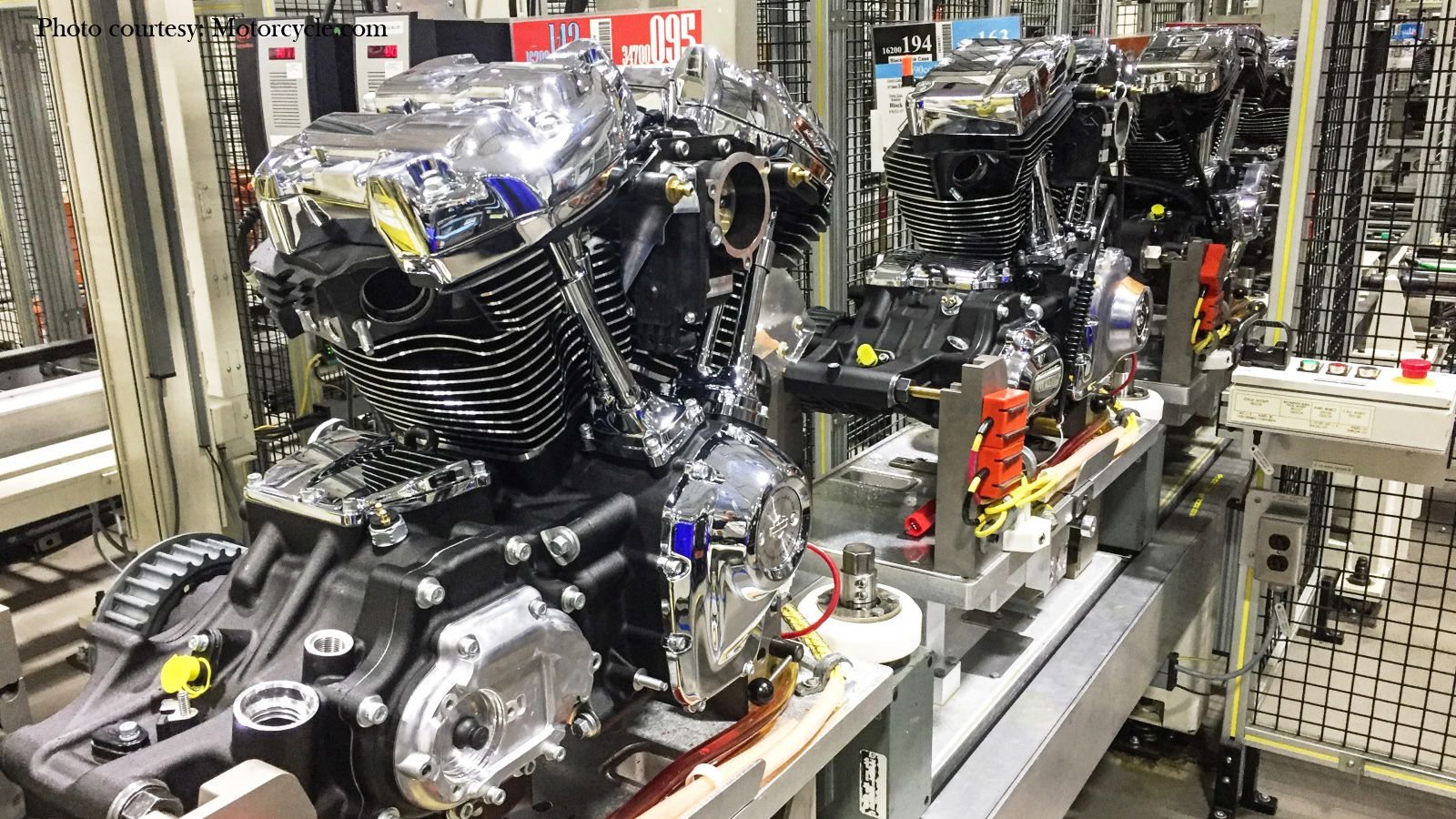

1. Birth of an Icon

It's about aura. The combination of heritage, appearance, soul, character and that cool factor that goes with the brand's indistinguishable heartbeat. Harley-Davidson's mega power train operations facility in Menomonee Falls, Wisconsin is huge at 912,000-square-foot and supplies the fertile environment necessary to create world class power plants. On the factory floor, humans and robots dance to a well choreographed ballet, exemplifying precision and timing. From this factory on Pilgram Road, engines and transmissions for Sportsters, Dynas, Softails and touring bikes head out to York, and Kansas City to be made into complete bikes.

2. Age of the Robots

Manipulators, end effectors, locomotion devices, controllers and sensors are blended to construct these robots which load and unload parts into various machine cells. Technicians perform tests and monitor equipment to endure accuracy of machinery, robots and computers. You might be surprised at how few humans are actually on the factory floor, if you take a tour of the place.

3. March Into the Future

Automated machines play an important part in keeping parts marching along with the cadence of a platoon. Quality control processes enables parts like heads, crankcases, and fly wheel to be bolted together, married and tested during manufacturing.

4. Tracking and Mating

Each example of each part has a unique code on it that allows for tracking throughout the process. Building the cases is completely automated. High pressure compressed air is supplied to mated surfaces to get rid of foreign matter. Humans don't actually touch the pieces until final assembly and inspection.

5. Humans vs. Machines

That human touch from a technician helps the automation process. Recipes are displayed showing fasteners, screws, widgets and clamps needed for assembly. At least 40 different engine configurations are produced at this plant. Currently they turn out powertrains in the Sportster, Twin Cam, and Milwaukee Eight families, in all their varieties.

6. Heatbeat of an Icon

Birth of the ultimate icon of the motorcycle world starts without a heartbeat. The completed powertrains are not run at the factory, but are spot checked, cranked, and subjected to external load test. 40 different test options are available. Once these powertrains leave the factory, the next stop on the journey to stardom could be the York, Kansas City, India or Brazil plants for final assembly. This is what makes a Harley, a Harley.

For more on how the motors get made, check out these stories from Hot Bike and Motorcycle.com

For help keeping your motor running right, see the how to section of HDForums.com