Soldering Tips?

#1

Hey guys,

I'll be doing some soldering work on the bike soon. Haven't done anything like this since shop class in high school (always used the crimp-on connectors when working on cars). Now I know the basics of soldering and consider myself to be pretty handy, but I want to make sure this gets done right the first time. Any tips/tricks for soldering wires?

I'll be doing some soldering work on the bike soon. Haven't done anything like this since shop class in high school (always used the crimp-on connectors when working on cars). Now I know the basics of soldering and consider myself to be pretty handy, but I want to make sure this gets done right the first time. Any tips/tricks for soldering wires?

#2

Hey guys,

I'll be doing some soldering work on the bike soon. Haven't done anything like this since shop class in high school (always used the crimp-on connectors when working on cars). Now I know the basics of soldering and consider myself to be pretty handy, but I want to make sure this gets done right the first time. Any tips/tricks for soldering wires?

I'll be doing some soldering work on the bike soon. Haven't done anything like this since shop class in high school (always used the crimp-on connectors when working on cars). Now I know the basics of soldering and consider myself to be pretty handy, but I want to make sure this gets done right the first time. Any tips/tricks for soldering wires?

#3

To avoid a cold soldier joint, heat both ends before applying the soldier.

If I'm soldiering a pin connector to a wire, I put the ping connector in a vise the lay the wire on top.

Use a broad tip on my soldier gun to heat both at the same time. The touch the soldier to the end of the wire, if hot enough it will draw the soldier over the wire. Do not keep the heat on once the soldier is in place. Practice with some junk wire a few times.

If I'm soldiering a pin connector to a wire, I put the ping connector in a vise the lay the wire on top.

Use a broad tip on my soldier gun to heat both at the same time. The touch the soldier to the end of the wire, if hot enough it will draw the soldier over the wire. Do not keep the heat on once the soldier is in place. Practice with some junk wire a few times.

#4

If the wire and terminal are both clean and you're using a high quality solder like Ersin Multi-Core, you shouldn't need any flux. If you use flux, don't use acid (plumber's) flux. It will cause corrosion down the road. Make sure you have a good mechanical connection before soldering. Apply heat to the joint with your iron, then apply solder to the joint. Solder should be drawn into the joint as you apply it if the joint was clean, and is hot enough. Do not use too much solder. Remove iron tip while solder is shiny.

#5

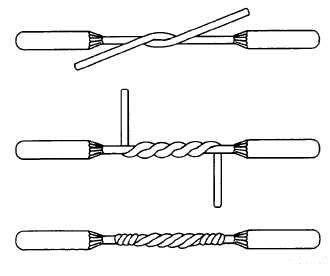

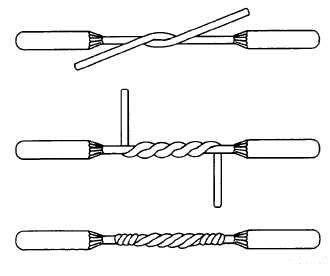

1) Strip the wires of about 1/2 in. of insulation. Slip PVC shrink tube over one wire. Twist the two sections of bare wire around each other.

2) Heat the joint with a soldering iron or pencil from underneath. Apply solder to the top until molten solder wicks into the joint. Let this cool undisturbed to avoid a "cold" solder joint.

3) Slide the shrink tubing over the soldered joint and heat the shrink tube to make it shrink down around the wire.

4) Use more shrink tube to bundle multiple connections.

Don't have a heat gun and your wife's hair dryer is off-limits? I've made do with a lighter.

2) Heat the joint with a soldering iron or pencil from underneath. Apply solder to the top until molten solder wicks into the joint. Let this cool undisturbed to avoid a "cold" solder joint.

3) Slide the shrink tubing over the soldered joint and heat the shrink tube to make it shrink down around the wire.

4) Use more shrink tube to bundle multiple connections.

Don't have a heat gun and your wife's hair dryer is off-limits? I've made do with a lighter.

#6

#7

Trending Topics

#8

Physically join the wires either with a Western Union splice or something similar (don't count on the solder to secure the joint.) And don't just pigtail the wire ends and bend it over as it makes it too bulky to heat shrink correctly.

Also "tin" the tip of your solder gun (for better heat transfer.) Get it hot, wipe with a damp sponge to clean, melt some new solder over it, shake off any excess, and keep the tip clean throughout the job with the sponge. You do want the solder to flow into the joint but not wick up under the insulation on the wires. If after you're done the wires are hard for a few inches on either side of the joint then you made the work too hot and used too much solder. Those areas need to stay pliable and may eventually fail (from vibration and/or bending) if too brittle.

Don't forget to slide your heat shrink up the wire before you solder the joint to avoid an "ah ****" moment! LOL . . .

Also "tin" the tip of your solder gun (for better heat transfer.) Get it hot, wipe with a damp sponge to clean, melt some new solder over it, shake off any excess, and keep the tip clean throughout the job with the sponge. You do want the solder to flow into the joint but not wick up under the insulation on the wires. If after you're done the wires are hard for a few inches on either side of the joint then you made the work too hot and used too much solder. Those areas need to stay pliable and may eventually fail (from vibration and/or bending) if too brittle.

Don't forget to slide your heat shrink up the wire before you solder the joint to avoid an "ah ****" moment! LOL . . .