Manufacturer dyno claims, dyno tests, tuning, seat of the pants feel, & questions

#1

Manufacturer dyno claims, dyno tests, tuning, seat of the pants feel, & many questions

I’m going to try to be as fair as I can with this posting, by noting facts, and only passing on opinions when I identify the opinions as such. I hope that those of you who have any interest andexperience in predicting and measuring engine performance might find this post interesting, and might be able to answer some of the questions I raise.

I have never been a dyno operator or engine tuner, but I have been around dynos and tuners for aslong as they have existed in the public domain (back around 1990, dynos and dyno tuners were NOT ‘on every street corner”).

I am going to apologize in advance for the length of the post, but I offer this explanation: I want to present actual evidence, not just my summarized analysis of that evidence, so you can draw your own conclusions, possibly different from mine, and raise your own questions, possible different from mine.

What this posting will cover:

I will:

- Examine some of Harley-Davidson’s rear wheel performance claims as shown by their rear wheel horsepower / rear wheel torque graphs in their current Screamin’ Eagle catalog

- Analyze the reasonableness of some of those claims

- Provide proof that the same brand of dyno apparently does not deliver the same dyno curves in two different shops, for the same unchanged bike a couple of hundred miles later

- Provide a testimonial as to how much difference a good tune makes

- Provide proof that using dyno results to help select exhaust systems is not as reliable a method as some of us may have thought, because the dyno results being relied upon are sometimes untrustworthy, incomplete, or inconsistent

This won’t be a theoretical presentation, but rather a very practical one, based upon a real life, current case: my personal bike.

The bike and the project:

My bike is a brand new 2014 Breakout (the standard version not the CVO version), with 103 cubic inch engine. As it comes from the factory, it is like every other Harley, in that its power is greatly “corked up” by super restrictive intake and exhaust systems, whose purpose is not performance. The purpose is rather making the bike legal for sale in the U.S. by restricting its sound level to comply with applicable laws. The restrictions required to achieve legal compliance for a Harley are much worse than for many other brands and types of motorcycles, because a large displacement, pushrod operated, air cooled twin cylinder engine is inherently pretty noisy.

The Starting point:

The rear wheel power and torque of the 103 engine, per Harley’s own dyno charts in the Screamin’ Eagle catalog, are about 64 rwhp and 81 ft lb of torque. This is in fact shown in this chart straight out of that catalog, as the “Stock 103” set of curves within the chart:

Note the other far more interesting curves in this chart, for the “Stage IV Racing Kit”. We’ll discuss them a lot more later.

Many (most?) Harley owners almost immediately replace the stock intake and exhaust systems with less restrictive ones coupled with a “canned” tune (a “Stage 1” kit), either Harley-branded or aftermarket, and immediately typically see those numbers change to about 75 to 80 rwhp and 95 to 100 ft lb of torque. This is huge bang for the buck, adding 11 to 16 rwhp for between $600 to $1000, depending on what part of the USA you live in, and how much or how little of the work you do yourself. So, you pay between $38 to $90 per rwhp. In the the high performance world of both bikes and cars, that’s a bargain price to add 17 to 25% more peak power to a vehicle.

The target:

Now note the other far more interesting curves in the chart above, the ones for the “Stage IV Racing Kit”. Here, we see 116 peak rwhp and about 115 rw torque. This looks really impressive. Until you analyze it sensibly.

This particular Stage 4 kit, the “racing” version as distinct from the Stage 4 “Street Legal” version elsewhere in the catalog, includes:

- CNC ported factory heads

- High performance valve springs

- Forged 10.5 compression ratio pistons

- SE259E cams (240 / 250 duration, .580” lift, and lots of valve overlap)

- Pushrods that can handle the higher valve lift

- 58mm throttle body

- Stronger clutch spring (to prevent clutch slippage with the higher power)

- HD Super Tuner for tuning the new combination of parts

The chart basically promises that if you install the Stage 4 kit, you’ll end up with 116 peak rwhp and 115 ft lb of torque.

Just stop and think about that claim. It means 80% more power than the stock 103, and 55 to 63% more power beyond Stage 1.

I happen to know from past experience that in both the bike and car world, you normally need a LOT more than the above Stage 4 collection of parts to get those kinds of power increases. Heck, to get a car engine to make just 40 to 50% more power, you typically need a supercharger or turbocharger. Even with a GM “LS series” engine, whose brilliant architecture responds particularly well to cam and exhaust improvements, you are doing very well if you get 40 to 50% power gains without a blower.

As part of my new bike deal, I had bought a “Stage 1 kit”. The same week I bought it, with only 68 miles on my Breakout, and the Stage 1 parts not yet actually at the dealership, my dealer called me and offered me a pretty nice deal to upgrade that Stage 1 kit to the Stage 4 race kit. I took my dealer up on the offer, because:

- the Stage 4 race kit is the highest power kit for my bike that HD sells

- I really wanted to keep my Breakout 100% Harley right now

- I wanted to deal with the local HD dealer that I have gone to for years for both Harley and non-Harley accessory and motorcycle clothing needs

- The quoted price was a reasonable deal if I really got anywhere at all CLOSE to 55 to 63% more power beyond Stage 1

The break-in process:

Normally, I would always dyno a bike or car before making a change like this, to get a reliable “baseline” to which to compare the actual improvements obtained. But, with only 68 miles on the Breakout, it would be both abusive and unproductive to dyno it before the installation of the kit, as we’d get poor results because the bike was not broken in yet, and we’ d risk damaging the engine. So, there was no baseline dyno run. This would, as you’ll see below, bite me later, because in skipping it, even though for good reason, I failed to see if the dyno at the HD dealership was consistent with the Stock 103 dyno results in the Screamin’ Eagle catalog.

After the kit was installed, I rode the bike for an additional 860 miles, beyond the 68 original miles, to break it in before dynoing it. My deal included a “4-hour dyno tuning session” which would be performed after the break-in. For the break-in period, the dealership loaded in a conservative temporary tune from their library of tunes, and told me to make sure I neither lugged the engine nor allowed it to get caught in overheat type traffic conditions. As I put on those miles, the dealership kept telling me that I would get a LOT better performance after the break-in and dyno tune.

Good thing too, as I was pretty unimpressed with the performance of the kit with the conservative tune during the break-in. I started out keeping the engine spinning between 2300 and 3000 rpm, avoiding steady state speeds and traffic jams, and gradually worked the rpm upward until after 500 miles I was revving it to 4500 rpm on some upshifts, and after about 700 miles, I allowed it to spin as high as 5000 rpm on some upshifts, but never at full throttle or higher, because I didn’t know if the temporary tune was “rich” enough at full throttle and high rpm to protect the engine.

Of course, this limited the performance I could expect to experience, but I really felt the low rpm performance was “adequate but not inspiring”, and attributed that to the combination of cam and exhaust. I had no right to complain about that, as I had after all selected a high rpm kit, and the bike seemed to be delivering pretty good performance in the 3000 to 5000 rpm range. I figured after the break-in was completed, and I got the dyno tune, it would probably feel like the exciting higher rpm engine I expected from the kit, but “being a Harley”, would likely never match the engine excitement of previous Ducati, Honda, and Suzuki (Hayabusa) sport superbikes I had owned.

(continued below)

I’m going to try to be as fair as I can with this posting, by noting facts, and only passing on opinions when I identify the opinions as such. I hope that those of you who have any interest andexperience in predicting and measuring engine performance might find this post interesting, and might be able to answer some of the questions I raise.

I have never been a dyno operator or engine tuner, but I have been around dynos and tuners for aslong as they have existed in the public domain (back around 1990, dynos and dyno tuners were NOT ‘on every street corner”).

I am going to apologize in advance for the length of the post, but I offer this explanation: I want to present actual evidence, not just my summarized analysis of that evidence, so you can draw your own conclusions, possibly different from mine, and raise your own questions, possible different from mine.

What this posting will cover:

I will:

- Examine some of Harley-Davidson’s rear wheel performance claims as shown by their rear wheel horsepower / rear wheel torque graphs in their current Screamin’ Eagle catalog

- Analyze the reasonableness of some of those claims

- Provide proof that the same brand of dyno apparently does not deliver the same dyno curves in two different shops, for the same unchanged bike a couple of hundred miles later

- Provide a testimonial as to how much difference a good tune makes

- Provide proof that using dyno results to help select exhaust systems is not as reliable a method as some of us may have thought, because the dyno results being relied upon are sometimes untrustworthy, incomplete, or inconsistent

This won’t be a theoretical presentation, but rather a very practical one, based upon a real life, current case: my personal bike.

The bike and the project:

My bike is a brand new 2014 Breakout (the standard version not the CVO version), with 103 cubic inch engine. As it comes from the factory, it is like every other Harley, in that its power is greatly “corked up” by super restrictive intake and exhaust systems, whose purpose is not performance. The purpose is rather making the bike legal for sale in the U.S. by restricting its sound level to comply with applicable laws. The restrictions required to achieve legal compliance for a Harley are much worse than for many other brands and types of motorcycles, because a large displacement, pushrod operated, air cooled twin cylinder engine is inherently pretty noisy.

The Starting point:

The rear wheel power and torque of the 103 engine, per Harley’s own dyno charts in the Screamin’ Eagle catalog, are about 64 rwhp and 81 ft lb of torque. This is in fact shown in this chart straight out of that catalog, as the “Stock 103” set of curves within the chart:

Note the other far more interesting curves in this chart, for the “Stage IV Racing Kit”. We’ll discuss them a lot more later.

Many (most?) Harley owners almost immediately replace the stock intake and exhaust systems with less restrictive ones coupled with a “canned” tune (a “Stage 1” kit), either Harley-branded or aftermarket, and immediately typically see those numbers change to about 75 to 80 rwhp and 95 to 100 ft lb of torque. This is huge bang for the buck, adding 11 to 16 rwhp for between $600 to $1000, depending on what part of the USA you live in, and how much or how little of the work you do yourself. So, you pay between $38 to $90 per rwhp. In the the high performance world of both bikes and cars, that’s a bargain price to add 17 to 25% more peak power to a vehicle.

The target:

Now note the other far more interesting curves in the chart above, the ones for the “Stage IV Racing Kit”. Here, we see 116 peak rwhp and about 115 rw torque. This looks really impressive. Until you analyze it sensibly.

This particular Stage 4 kit, the “racing” version as distinct from the Stage 4 “Street Legal” version elsewhere in the catalog, includes:

- CNC ported factory heads

- High performance valve springs

- Forged 10.5 compression ratio pistons

- SE259E cams (240 / 250 duration, .580” lift, and lots of valve overlap)

- Pushrods that can handle the higher valve lift

- 58mm throttle body

- Stronger clutch spring (to prevent clutch slippage with the higher power)

- HD Super Tuner for tuning the new combination of parts

The chart basically promises that if you install the Stage 4 kit, you’ll end up with 116 peak rwhp and 115 ft lb of torque.

Just stop and think about that claim. It means 80% more power than the stock 103, and 55 to 63% more power beyond Stage 1.

I happen to know from past experience that in both the bike and car world, you normally need a LOT more than the above Stage 4 collection of parts to get those kinds of power increases. Heck, to get a car engine to make just 40 to 50% more power, you typically need a supercharger or turbocharger. Even with a GM “LS series” engine, whose brilliant architecture responds particularly well to cam and exhaust improvements, you are doing very well if you get 40 to 50% power gains without a blower.

As part of my new bike deal, I had bought a “Stage 1 kit”. The same week I bought it, with only 68 miles on my Breakout, and the Stage 1 parts not yet actually at the dealership, my dealer called me and offered me a pretty nice deal to upgrade that Stage 1 kit to the Stage 4 race kit. I took my dealer up on the offer, because:

- the Stage 4 race kit is the highest power kit for my bike that HD sells

- I really wanted to keep my Breakout 100% Harley right now

- I wanted to deal with the local HD dealer that I have gone to for years for both Harley and non-Harley accessory and motorcycle clothing needs

- The quoted price was a reasonable deal if I really got anywhere at all CLOSE to 55 to 63% more power beyond Stage 1

The break-in process:

Normally, I would always dyno a bike or car before making a change like this, to get a reliable “baseline” to which to compare the actual improvements obtained. But, with only 68 miles on the Breakout, it would be both abusive and unproductive to dyno it before the installation of the kit, as we’d get poor results because the bike was not broken in yet, and we’ d risk damaging the engine. So, there was no baseline dyno run. This would, as you’ll see below, bite me later, because in skipping it, even though for good reason, I failed to see if the dyno at the HD dealership was consistent with the Stock 103 dyno results in the Screamin’ Eagle catalog.

After the kit was installed, I rode the bike for an additional 860 miles, beyond the 68 original miles, to break it in before dynoing it. My deal included a “4-hour dyno tuning session” which would be performed after the break-in. For the break-in period, the dealership loaded in a conservative temporary tune from their library of tunes, and told me to make sure I neither lugged the engine nor allowed it to get caught in overheat type traffic conditions. As I put on those miles, the dealership kept telling me that I would get a LOT better performance after the break-in and dyno tune.

Good thing too, as I was pretty unimpressed with the performance of the kit with the conservative tune during the break-in. I started out keeping the engine spinning between 2300 and 3000 rpm, avoiding steady state speeds and traffic jams, and gradually worked the rpm upward until after 500 miles I was revving it to 4500 rpm on some upshifts, and after about 700 miles, I allowed it to spin as high as 5000 rpm on some upshifts, but never at full throttle or higher, because I didn’t know if the temporary tune was “rich” enough at full throttle and high rpm to protect the engine.

Of course, this limited the performance I could expect to experience, but I really felt the low rpm performance was “adequate but not inspiring”, and attributed that to the combination of cam and exhaust. I had no right to complain about that, as I had after all selected a high rpm kit, and the bike seemed to be delivering pretty good performance in the 3000 to 5000 rpm range. I figured after the break-in was completed, and I got the dyno tune, it would probably feel like the exciting higher rpm engine I expected from the kit, but “being a Harley”, would likely never match the engine excitement of previous Ducati, Honda, and Suzuki (Hayabusa) sport superbikes I had owned.

(continued below)

#2

The First Reported Results:

The break-in ended one recent Saturday after I showed up for the pre-scheduled dyno tune at the HD dealership, with about 930 miles on the bike. Both the Stage 4 installation and the dyno tune were done by the best technician in the dealership. He is one of only 2 technicians there who do all the dynowork, is acknowledged to be the best by everyone, and he is also, at my request, the only technician who has ever worked on my Breakout (He also did the chrome Turbine wheels, disks, and rear pulley). So, ALL the work on my bike was done by the acknowledged very best technician in the entire dealership. Remember that later.

After 3 to 4 hours of work, I was told my bike was ready, and the paper dyno chart was attached to the work order. I have to admit I was rather disappointed when I saw the chart, which looked like this:

Notice:

- The data has been properly corrected to SAE standard conditions (versus the older STD standard, which gave higher but less realistic results)

- The SAE correction factor is 1.01, which is excellent. It means that the actual ambient conditions at the time of the dyno testing were close enough (within 1%) to SAE standard temperature, barometric pressure, and humidity to provide a reliable reading. (A bad set of environmental conditions would be 1.05 (i.e. 5% off), at which point the results have to be viewed as only marginally believable0. However, the technician’s mixing of English and metric units for the ambient conditions (see the notes under the graph) is a little sloppy.

- The technician incorrectly identified the exhaust as the D&D “Fat Cat” when it is actually the “Low Cat”. The difference is important. The Fat Cat would drag very easily on my Breakout, which is even lower than stock. In addition, it is possible that the slight upward tilt in the Low Cat compared to the Fat Cat (to provide more ground clearance on lowered bikes) affects the exhaust’s performance, so this labeling error is a notably bad one.

- The scaling is needlessly confusing, with the torque scale on the right hand side of the graph being inexplicably different than the horsepower scaling, even though both could easily have been done on exactly the same scaling. There is no way to sugar coat this: it is sloppy dyno reporting that can easily mislead a reader, as the scales are different but close enough that some readers wouldn’t even notice they are different.

- The technician started the dyno run at 2600 rpm. This is defensible in this case, because the cam set is a high rpm cam set, and it can legitimately be argued that the low rpm results are not expected to be particularly good, and it is somewhat abusive to apply full throttle to a high rpm engine at low rpm. However, as you will see later, it caused the technician to “miss” something very important about the power and torque curves, and because he did not see it, and all I got was the paper graph that recorded what he saw, I missed that something important as well. That really annoyed me once the missing data became visible to me later.

- The “Dynojet Resarch” dyno brand name is almost completely overwhelmed on the printout by the advertising for the dealership, but if you look right above the center of the graph, you will see it. This WAS done on a standard Dynojet dynamometer.

- Incredibly, the air-fuel ratio was not even graphed on the chart I was given!

- Neither the technician performing the dyno tuning and testing nor the 2nd technician experienced on the dyno offered me an electronic version of any of the multiple runs they did. When I finally ASKED for it, incredibly, neither was able to copy and paste my Dynojet .drf file from the dyno run library into an email to send to me! I offered to do it myself while they watched, but they wouldn’t allow me to.

- The peak horsepower is only 103.6, which is pretty damn far from the116 promised in the HD chart we looked at above. Like almost 11% low.

- The torque curve is much worse. Whereas I keep hearing about dyno sheets that apparently show modded103 engines with torque curves that are mostly above 100 foot pounds, my Breakout NEVER got to 100 ft lb at ALL on this run!

- These low numbers are particularly puzzling since the peak torque occurs at a very healthy 4750 rpm. This is important. Per HD’s data in the Screamin’ Eagle catalog, the 259E cam set is supposed to produce its peak torque at around 4000 rpm, not 4750. So, the 4750 torque peak shows conclusively that this combination of cam, heads, intake, and exhaust really flows air well. But, if it does, why is the peak torque value so low compared to the HD graph above, where the torque peaked at a much lower 4000 rpm? (as predicted by the cam specs). This makes no sense. An engine that breathes well enough to make its peak torque at 4750 rpm, and that is still CLIMBING in horsepower when it hits redline at 6200, should, you would think, be matching at least the results promised by HD in their graph. IF the graph is an honest representation of what the buyer of the kit should expect. IS IT?

- When I asked about this relatively major shortfall versus catalog promise, both technicians first told me that “those graphs are flywheel horsepower, not rear wheel”. When I pointed to the note right on the vertical scale of the graph that states it is rear wheel horsepower, they were embarrassed, and moved on to the next excuse: “They (other bikes they have dynoed) are ALL like that.” They even showed me another Stage 4 Race kit Breakout dyno sheet, where the owner had installed Vance & Hines “Radius” exhaust (that’s the way they had recorded the name), and pointed out that his bike made virtually identical peak power (102.5 versus 103.6). When I countered that none of that explains why BOTH bikes missed the catalog promise by 11%, they used their third excuse: “Your exhaust is too small. You need more muffler volume, like the touring bikes”. I countered that most 2 into 1 Harley exhausts I have ever seen have relatively small and short mufflers, and that the exhaust pipe industry seems to think that that is the way to build a 2 into 1 for best effectiveness.

Now I like this HD dealership a lot, and have generally over many years had very good experiences there with the sales people, the accessories people, the parts people, AND the service technicians. But, after all the above on this dyno business, I could not tell them that I am happy with the way it was done, and they know very clearly now that while I like the dealership as a whole, I expect more dyno expertise, and I need to find it elsewhere.

The Second Reported Results:

Because there were so many anomalies visible in this dealership dyno graph, and also in the analysis that I did of the HD catalog data, I made the effort to find another shop, an independent shop, located nearby, that also has a Dynojet dyno. I had the bike re-dyoned there. Very interesting outcome.

First, at the indy shop, the owner of the shop is also the dyno operator and dyno tuner.

Secondly, this indy shop basically does Harley & S&S work only, so, like the HD dealership, work on HD-based bikes is their bread and butter work.

Thirdly, I showed him the HD catalog description of the Stage 4 Race kit, without yet showing him the HD graph. I asked him what kind of power and torque he would predict that kit to make. He said a buyer should expect about 100 rwhp and similar peak torque, maybe a bit more if the work was well done. Then I showed him the HD graph, at which point he said “no way”, and reiterated that at least on his Dynojet dyno, that combination of parts would make 100 rwhp.

Then he set up my 3 dyno runs, and I, having attended a LOT of dyno runs over the past couple of decades, watched him carefully. He did everything right. Some examples:

- carefully recorded EVERYTHING about the bike and the parts on it

- checked and set the rear tire pressure

- used fleece-lined covers over the tiedowns wherever they touched the bike

- carefully warmed up the bike, with his dyno fans shut off for the warmup

- Turned on both heavy duty dyno fans before starting the runs

- Explained that he would start the runs just above 2000 rpm to catch as much as possible of the entire rpm range, but would not go below that because it would be abusive to the engine given its type and cams

- Produced a graph that showed AFR, hp, and torque

- Readily agreed to provide the Dynojet .drf file, and we worked together to email it to my email address

Here is the chart that he produced:

Note:

- The peak horsepower and torque are just very slightly above what the Indy tuner predicted before he dynode the bike. Remember, he said 100 or maybe a bit above if the work was well done. And he has dynoed a LOT of modded Harleys

- The peak horsepower value is very similar: 104.4 rwhp, versus the 103.5 at the HD dealership, easily within the error range for even well calibrated dynos and skilled operators

- However, the power curve is “fatter” (higher average values) because the torque curve is different (HP = Torque x RPM/5252)

- The shape of the torque curve is notably different. We’ll compare the dealership curve and the Indy curve below, but note now that the peak value is higher: 102.6, and that the torque curve stays above 100 from at least 3900 rpm to over 5000 rpm

- Note that the downward slope of the torque curve reverses itself at around 2600 rpm, which is why the dealership tech missed it when he started the dyno run at 2600. The torque curve climbs upward as the rpm decreases to 2000 and below. Remember this, because it explains some significant things we will discuss below in the “analysis” and “seat of the pants” sections

- Note that the AFR (air fuel ratio) curve LOOKS dramatic, but that’s only because I have deliberately scaled that graph to greatly emphasize the anomaly centered on the 2000 to 3000 rpm range. The actual “amplitude of the anomaly is only a maximum of ½ point off in either direction. The dealership tuner did a pretty good job everywhere else. More on this below.

- Note how gorgeous the shape of the torque curve is. It has a remarkably broad torque peak (3800 to 5100 rpm), located at a very high rpm range. This is very desirable (for a “sporty cruiser” Harley, not for a tourer Harley).

(continued below)

The break-in ended one recent Saturday after I showed up for the pre-scheduled dyno tune at the HD dealership, with about 930 miles on the bike. Both the Stage 4 installation and the dyno tune were done by the best technician in the dealership. He is one of only 2 technicians there who do all the dynowork, is acknowledged to be the best by everyone, and he is also, at my request, the only technician who has ever worked on my Breakout (He also did the chrome Turbine wheels, disks, and rear pulley). So, ALL the work on my bike was done by the acknowledged very best technician in the entire dealership. Remember that later.

After 3 to 4 hours of work, I was told my bike was ready, and the paper dyno chart was attached to the work order. I have to admit I was rather disappointed when I saw the chart, which looked like this:

Notice:

- The data has been properly corrected to SAE standard conditions (versus the older STD standard, which gave higher but less realistic results)

- The SAE correction factor is 1.01, which is excellent. It means that the actual ambient conditions at the time of the dyno testing were close enough (within 1%) to SAE standard temperature, barometric pressure, and humidity to provide a reliable reading. (A bad set of environmental conditions would be 1.05 (i.e. 5% off), at which point the results have to be viewed as only marginally believable0. However, the technician’s mixing of English and metric units for the ambient conditions (see the notes under the graph) is a little sloppy.

- The technician incorrectly identified the exhaust as the D&D “Fat Cat” when it is actually the “Low Cat”. The difference is important. The Fat Cat would drag very easily on my Breakout, which is even lower than stock. In addition, it is possible that the slight upward tilt in the Low Cat compared to the Fat Cat (to provide more ground clearance on lowered bikes) affects the exhaust’s performance, so this labeling error is a notably bad one.

- The scaling is needlessly confusing, with the torque scale on the right hand side of the graph being inexplicably different than the horsepower scaling, even though both could easily have been done on exactly the same scaling. There is no way to sugar coat this: it is sloppy dyno reporting that can easily mislead a reader, as the scales are different but close enough that some readers wouldn’t even notice they are different.

- The technician started the dyno run at 2600 rpm. This is defensible in this case, because the cam set is a high rpm cam set, and it can legitimately be argued that the low rpm results are not expected to be particularly good, and it is somewhat abusive to apply full throttle to a high rpm engine at low rpm. However, as you will see later, it caused the technician to “miss” something very important about the power and torque curves, and because he did not see it, and all I got was the paper graph that recorded what he saw, I missed that something important as well. That really annoyed me once the missing data became visible to me later.

- The “Dynojet Resarch” dyno brand name is almost completely overwhelmed on the printout by the advertising for the dealership, but if you look right above the center of the graph, you will see it. This WAS done on a standard Dynojet dynamometer.

- Incredibly, the air-fuel ratio was not even graphed on the chart I was given!

- Neither the technician performing the dyno tuning and testing nor the 2nd technician experienced on the dyno offered me an electronic version of any of the multiple runs they did. When I finally ASKED for it, incredibly, neither was able to copy and paste my Dynojet .drf file from the dyno run library into an email to send to me! I offered to do it myself while they watched, but they wouldn’t allow me to.

- The peak horsepower is only 103.6, which is pretty damn far from the116 promised in the HD chart we looked at above. Like almost 11% low.

- The torque curve is much worse. Whereas I keep hearing about dyno sheets that apparently show modded103 engines with torque curves that are mostly above 100 foot pounds, my Breakout NEVER got to 100 ft lb at ALL on this run!

- These low numbers are particularly puzzling since the peak torque occurs at a very healthy 4750 rpm. This is important. Per HD’s data in the Screamin’ Eagle catalog, the 259E cam set is supposed to produce its peak torque at around 4000 rpm, not 4750. So, the 4750 torque peak shows conclusively that this combination of cam, heads, intake, and exhaust really flows air well. But, if it does, why is the peak torque value so low compared to the HD graph above, where the torque peaked at a much lower 4000 rpm? (as predicted by the cam specs). This makes no sense. An engine that breathes well enough to make its peak torque at 4750 rpm, and that is still CLIMBING in horsepower when it hits redline at 6200, should, you would think, be matching at least the results promised by HD in their graph. IF the graph is an honest representation of what the buyer of the kit should expect. IS IT?

- When I asked about this relatively major shortfall versus catalog promise, both technicians first told me that “those graphs are flywheel horsepower, not rear wheel”. When I pointed to the note right on the vertical scale of the graph that states it is rear wheel horsepower, they were embarrassed, and moved on to the next excuse: “They (other bikes they have dynoed) are ALL like that.” They even showed me another Stage 4 Race kit Breakout dyno sheet, where the owner had installed Vance & Hines “Radius” exhaust (that’s the way they had recorded the name), and pointed out that his bike made virtually identical peak power (102.5 versus 103.6). When I countered that none of that explains why BOTH bikes missed the catalog promise by 11%, they used their third excuse: “Your exhaust is too small. You need more muffler volume, like the touring bikes”. I countered that most 2 into 1 Harley exhausts I have ever seen have relatively small and short mufflers, and that the exhaust pipe industry seems to think that that is the way to build a 2 into 1 for best effectiveness.

Now I like this HD dealership a lot, and have generally over many years had very good experiences there with the sales people, the accessories people, the parts people, AND the service technicians. But, after all the above on this dyno business, I could not tell them that I am happy with the way it was done, and they know very clearly now that while I like the dealership as a whole, I expect more dyno expertise, and I need to find it elsewhere.

The Second Reported Results:

Because there were so many anomalies visible in this dealership dyno graph, and also in the analysis that I did of the HD catalog data, I made the effort to find another shop, an independent shop, located nearby, that also has a Dynojet dyno. I had the bike re-dyoned there. Very interesting outcome.

First, at the indy shop, the owner of the shop is also the dyno operator and dyno tuner.

Secondly, this indy shop basically does Harley & S&S work only, so, like the HD dealership, work on HD-based bikes is their bread and butter work.

Thirdly, I showed him the HD catalog description of the Stage 4 Race kit, without yet showing him the HD graph. I asked him what kind of power and torque he would predict that kit to make. He said a buyer should expect about 100 rwhp and similar peak torque, maybe a bit more if the work was well done. Then I showed him the HD graph, at which point he said “no way”, and reiterated that at least on his Dynojet dyno, that combination of parts would make 100 rwhp.

Then he set up my 3 dyno runs, and I, having attended a LOT of dyno runs over the past couple of decades, watched him carefully. He did everything right. Some examples:

- carefully recorded EVERYTHING about the bike and the parts on it

- checked and set the rear tire pressure

- used fleece-lined covers over the tiedowns wherever they touched the bike

- carefully warmed up the bike, with his dyno fans shut off for the warmup

- Turned on both heavy duty dyno fans before starting the runs

- Explained that he would start the runs just above 2000 rpm to catch as much as possible of the entire rpm range, but would not go below that because it would be abusive to the engine given its type and cams

- Produced a graph that showed AFR, hp, and torque

- Readily agreed to provide the Dynojet .drf file, and we worked together to email it to my email address

Here is the chart that he produced:

Note:

- The peak horsepower and torque are just very slightly above what the Indy tuner predicted before he dynode the bike. Remember, he said 100 or maybe a bit above if the work was well done. And he has dynoed a LOT of modded Harleys

- The peak horsepower value is very similar: 104.4 rwhp, versus the 103.5 at the HD dealership, easily within the error range for even well calibrated dynos and skilled operators

- However, the power curve is “fatter” (higher average values) because the torque curve is different (HP = Torque x RPM/5252)

- The shape of the torque curve is notably different. We’ll compare the dealership curve and the Indy curve below, but note now that the peak value is higher: 102.6, and that the torque curve stays above 100 from at least 3900 rpm to over 5000 rpm

- Note that the downward slope of the torque curve reverses itself at around 2600 rpm, which is why the dealership tech missed it when he started the dyno run at 2600. The torque curve climbs upward as the rpm decreases to 2000 and below. Remember this, because it explains some significant things we will discuss below in the “analysis” and “seat of the pants” sections

- Note that the AFR (air fuel ratio) curve LOOKS dramatic, but that’s only because I have deliberately scaled that graph to greatly emphasize the anomaly centered on the 2000 to 3000 rpm range. The actual “amplitude of the anomaly is only a maximum of ½ point off in either direction. The dealership tuner did a pretty good job everywhere else. More on this below.

- Note how gorgeous the shape of the torque curve is. It has a remarkably broad torque peak (3800 to 5100 rpm), located at a very high rpm range. This is very desirable (for a “sporty cruiser” Harley, not for a tourer Harley).

(continued below)

Last edited by JimGnitecki; 05-04-2014 at 10:47 AM.

#3

The comparison between the 2 dyno charts:

Here is a graph that I created that compares the two sets of dyno curves from the two supposedly identical Dynojet dynamometers:

It shows that these two curve sets are not anywhere near identical.

Note that:

- There is only a 1% difference in peak horsepower value, but the total areas “under the curve” for the power and torque curves are 6% higher. Since the impact of a very good exhaust change for example is this percent or less, this has to be considered an unacceptable variance between two same brand, supposedly properly calibrated dynos.

- More significantly yet, the SHAPE of the torque curve is notably different. The dealership curve made me ask “what’s wrong with my exhaust to make this steeply sloped torque curve with narrow peak?” The Indy torque curve says to me that regardless of the reported numerical dyno values, this IS the right combination of cam, heads, compression, and exhaust. That torque curve is beautiful.

- The dealership dyno run, and consequently the resulting graph of the torque curve, missed entirely the upward torque blip around 2000 rpm. That blip is very important, as you’ll read below.

The analysis:

Below is a graph that I prepared, based on HD’s own Screamin’ Eagle catalog dyno charts (including the one above), that examines the reasonableness of the HD charts and the projected power gains they promise:

Note the following (if you can believe it):

- The Stage 4 Race kit is claimed by HD to make 81% more peak power than the stock 103. Can cams, CNC heads, and 10.5 pistons really do that much?

- The stock 110 engine makes only 25% more peak power than the stock 103

- The most aggressive HD kit available for the 110, the Stage 3, makes only 61% more peak power than the stock 103, while the 103 Stage 4 kit makes 81% more?

- My own Breakout, with the gorgeous and pretty perfect high rpm torque curve makes 63% more power than the stock 103, but misses the HD chart promise for a Stage 4 103 by 10% regardless. That’s hard to believe.

- My own Breakout, with the gorgeous and pretty perfect high rpm torque curve makes 54% more total power “under the curve” than the stock 103, surpassing the Stage 3 110 kit’s 41%, but misses the HD chart promise for a Stage 4 103 by 14% regardless. That’s hard to believe.

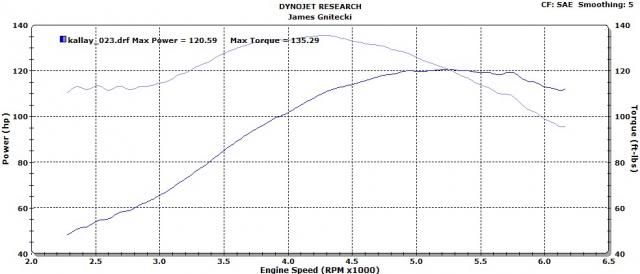

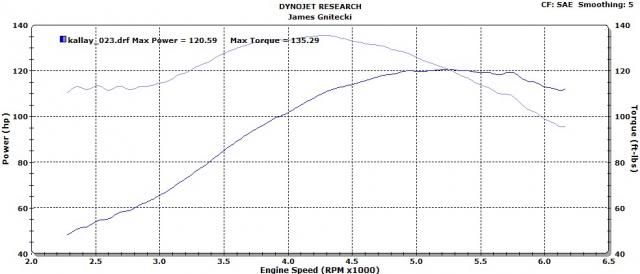

Here’s a graph that the Indy tuner let me email to myself, from his library of tunes. It also happens to be the dyno chart for one of his own personal bikes, so he knows there’s nothing wrong with the bike. And he believes there is nothing wrong with his dyno.

This graph is for an Ultima 127 engine. The manufacturer claims it makes 140 rwhp at peak, and 145 rw ft lb of torque.

Notice that the peak rwhp actually obtained on the Indy’s dyno is 120.6, and the maximum actual torque is 135.3. That peak rwhp is 14% off the manufacturer’s claim, and that peak torque is 7% off the manufacturer’s claim.

Notice that the two shortfalls, 7% and 14%, are different. That means this is not just a dyno brand difference or dyno calibration problem, but rather that like in the case of my dealer dyno chart versus my Indy dyno chart , there is a difference in the SHAPE of the curve. That is worrying, It prompts me to ask whether we can we trust ANY dyno chart?

Here are the Volumetric Efficiency (VE) tables for my Breakout, after the dyno tune at the dealership:

Notice the TWO peaks in volumetric efficiency. There is one where we expect it to be: at the rpm range where the peak torque appears on the dyno curve. But, notice the second peak, at around 2000 rpm. Interestingly, this one at 2000 is HIGHER. Is this why the bike feels the way I describe below?

(continued below)

Here is a graph that I created that compares the two sets of dyno curves from the two supposedly identical Dynojet dynamometers:

It shows that these two curve sets are not anywhere near identical.

Note that:

- There is only a 1% difference in peak horsepower value, but the total areas “under the curve” for the power and torque curves are 6% higher. Since the impact of a very good exhaust change for example is this percent or less, this has to be considered an unacceptable variance between two same brand, supposedly properly calibrated dynos.

- More significantly yet, the SHAPE of the torque curve is notably different. The dealership curve made me ask “what’s wrong with my exhaust to make this steeply sloped torque curve with narrow peak?” The Indy torque curve says to me that regardless of the reported numerical dyno values, this IS the right combination of cam, heads, compression, and exhaust. That torque curve is beautiful.

- The dealership dyno run, and consequently the resulting graph of the torque curve, missed entirely the upward torque blip around 2000 rpm. That blip is very important, as you’ll read below.

The analysis:

Below is a graph that I prepared, based on HD’s own Screamin’ Eagle catalog dyno charts (including the one above), that examines the reasonableness of the HD charts and the projected power gains they promise:

Note the following (if you can believe it):

- The Stage 4 Race kit is claimed by HD to make 81% more peak power than the stock 103. Can cams, CNC heads, and 10.5 pistons really do that much?

- The stock 110 engine makes only 25% more peak power than the stock 103

- The most aggressive HD kit available for the 110, the Stage 3, makes only 61% more peak power than the stock 103, while the 103 Stage 4 kit makes 81% more?

- My own Breakout, with the gorgeous and pretty perfect high rpm torque curve makes 63% more power than the stock 103, but misses the HD chart promise for a Stage 4 103 by 10% regardless. That’s hard to believe.

- My own Breakout, with the gorgeous and pretty perfect high rpm torque curve makes 54% more total power “under the curve” than the stock 103, surpassing the Stage 3 110 kit’s 41%, but misses the HD chart promise for a Stage 4 103 by 14% regardless. That’s hard to believe.

Here’s a graph that the Indy tuner let me email to myself, from his library of tunes. It also happens to be the dyno chart for one of his own personal bikes, so he knows there’s nothing wrong with the bike. And he believes there is nothing wrong with his dyno.

This graph is for an Ultima 127 engine. The manufacturer claims it makes 140 rwhp at peak, and 145 rw ft lb of torque.

Notice that the peak rwhp actually obtained on the Indy’s dyno is 120.6, and the maximum actual torque is 135.3. That peak rwhp is 14% off the manufacturer’s claim, and that peak torque is 7% off the manufacturer’s claim.

Notice that the two shortfalls, 7% and 14%, are different. That means this is not just a dyno brand difference or dyno calibration problem, but rather that like in the case of my dealer dyno chart versus my Indy dyno chart , there is a difference in the SHAPE of the curve. That is worrying, It prompts me to ask whether we can we trust ANY dyno chart?

Here are the Volumetric Efficiency (VE) tables for my Breakout, after the dyno tune at the dealership:

Notice the TWO peaks in volumetric efficiency. There is one where we expect it to be: at the rpm range where the peak torque appears on the dyno curve. But, notice the second peak, at around 2000 rpm. Interestingly, this one at 2000 is HIGHER. Is this why the bike feels the way I describe below?

(continued below)

#4

The On-the-road seat-of the pants-feel, and value of a good dyno tune:

The dyno charts, either of them, may not be very impressive in their numerical values compared to what some others have claimed, and they are puzzling in their difference, but after the dyno tune (not before), the on the road performance is fantastic.

This engine feels so strong at both the bottom of the rpm range and at the top of the rpm range.

The bottom end is particularly impressive. When riding in traffic where I am watching the cars around me intently, I don’t have time to check the tach. When I do get a chance to look, I often find myself riding at 1500 rpm, and quickly downshift! The bike pulls awfully well from low rpm, and cruises at 2000 if I want it to (I prefer to keep the rpm higher just because), despite the cam. Is it the exhaust doing this or?

The top end is a strong rush all the way to the rev limit, with no gaps or surges.

Throttle response is very crisp. In fact, when I blip the throttle to synchronize rpm to road speed on downshifts, it’s as crisp as breaking glass.

Judging by the on the road seat of the pants feel, the HD dealership technician did a pretty good job. I really can’t criticize anything about the feel and performance of the engine.

And, the dyno tune improved the bike’s engine feel astronomically. It feels like an entirely different bike.

Theories:

The AFR anomaly in the 2000 to 3000 rpm range is located right in the “dip” where the torque reverses direction. It is also right adjacent to where the VE table has that big peak. It’s a busy area.

I asked a really good friend about it. He is a talented racer, engine tuner, and dyno guru, who also runs a motorcycle sales dealership (not Harley) and dyno tuning service (all makes of bikes). He tunes a lot of bikes including modified Harleys. He thinks the AFR difficulty that the HD technician encountered is due to reversion. He says he sees it a lot on Harleys.

He also told me that he sees that dip in the torque curve on every Harley significantly modified for more power, whether the exhaust is a 2 into 1 or true duals or whatever. He says it is a direct result of the cam timing needed to get high power. In fact, he showed me a bunch of actual before and after dyno curves for Harley’s modded similar to mine, and two things struck me:

- All of them had a dip in the torque curve

- None of them made more than 100 rwhp

By the way, his dyno is a different brand – a Factory Pro.

Now, a horsepower is supposedly a horsepower, no matter what dyno it was measured on. But if so, why do the best modded Harleys dynode on his dyno still ALL produce significantly less power and torque than the power and torque shown in Harley’s Stage 4 graph? Is the air and fuel around Milwaukee better than elsewhere? ☺

A theory (just a theory) that I would advance to explain the difference in the shape of the curves at the HD dealership and the Indy is that MAYBE the dealership tech ran the dyno tests in 4th gear, whereas the Indy ran it in 5th. The significance is that the entire run at the Indy, for each of the 3 runs, was well under 10 seconds – something like 8 seconds, as I recall from analyzing the Dynojet drf file. IF the HD tech ran his dyno runs in 4th gear, the runs would have been shorter, since the engine can accelerate the dyno drum faster in 4th than in 5th. That of course means the engine also accelerates its own entire drivetrain faster in 4th than in 5th.

But to accelerate the drivetrain, the engine must overcome the COMBINED moment of inertia of the entire drivetrain: flywheel, primary drive, transmission, final drive, and rear wheel. The engine never “gets credit” for producing that power consumed to spin up the drivetrain from the bottom of the engine rpm range all the way to the top, because that diverted power never gets to the dyno drum.

The combined moment of inertia for a Harley drivetrain is very high, because you need big heavy driveline components when your engine is a low rpm high torque engine, versus the high rpm, low torque engines used in most Japanese, Korean, and European bikes. If they aren’t big and heavy, the break under the big torque loads.

The moment of inertia on my Breakout is higher than stock too, since I have the chrome Turbine wheel, which is very heavy, both because it is a billet wheel, and because it is very wide – it mounts a 240 tire.

Furthermore, the diversion of power from spinning up the dyno drum to spinning up the drivetrain is going to have a PROPORTIONATELY greater effect at the lower end of the rpm rnage on the dyno, than at the high end, since there is far less TOTAL engine power available at low rpm than at high rpm.

It seems logical therefore that the diversion of some of the engine’s power to overcome drivetrain moment of inertia would tend to lower the power and therefore torque curves proportionately more at lower rpm than at high rpm. That COULD explain why the torque curve seems a bit low at lower rpm. Equally importantly, it could explain why the HD dealership’s dyno curves show MORE of that lower-torque-at-lower-rpm effect, IF they ran their tests in 4th gear.

Of course, I don’t know what gear the HD dealership ran the dyno tests in, since they wouldn’t give me the Dynojet .drf file (which would clearly show what gear they ran the tests in).

Conclusions:

After all the above, here is what I am personally concluding:

- HD’s Screamin’ Eagle dyno charts, or at least the one for the 103 Stage 4 Race kit, are untrustworthy. You cannot count on getting the results they predict, which makes them useless

- The Stage4 race kit is still worth getting, because it transforms the engine from “weak” to “satisfying”, but its cost per achieved horsepower is way higher than HD’s chart would lead you to believe

- The same brand of dyno at two different shops will not necessarily produce the same dyno curves for the same bike

- Dyno curves cannot be trusted to accurately guide exhaust system experiments

- Some dyno operators are way more knowledgeable, skilled, and comprehensive than others

- A dyno TUNE is REALLY worth getting

Jim G

The dyno charts, either of them, may not be very impressive in their numerical values compared to what some others have claimed, and they are puzzling in their difference, but after the dyno tune (not before), the on the road performance is fantastic.

This engine feels so strong at both the bottom of the rpm range and at the top of the rpm range.

The bottom end is particularly impressive. When riding in traffic where I am watching the cars around me intently, I don’t have time to check the tach. When I do get a chance to look, I often find myself riding at 1500 rpm, and quickly downshift! The bike pulls awfully well from low rpm, and cruises at 2000 if I want it to (I prefer to keep the rpm higher just because), despite the cam. Is it the exhaust doing this or?

The top end is a strong rush all the way to the rev limit, with no gaps or surges.

Throttle response is very crisp. In fact, when I blip the throttle to synchronize rpm to road speed on downshifts, it’s as crisp as breaking glass.

Judging by the on the road seat of the pants feel, the HD dealership technician did a pretty good job. I really can’t criticize anything about the feel and performance of the engine.

And, the dyno tune improved the bike’s engine feel astronomically. It feels like an entirely different bike.

Theories:

The AFR anomaly in the 2000 to 3000 rpm range is located right in the “dip” where the torque reverses direction. It is also right adjacent to where the VE table has that big peak. It’s a busy area.

I asked a really good friend about it. He is a talented racer, engine tuner, and dyno guru, who also runs a motorcycle sales dealership (not Harley) and dyno tuning service (all makes of bikes). He tunes a lot of bikes including modified Harleys. He thinks the AFR difficulty that the HD technician encountered is due to reversion. He says he sees it a lot on Harleys.

He also told me that he sees that dip in the torque curve on every Harley significantly modified for more power, whether the exhaust is a 2 into 1 or true duals or whatever. He says it is a direct result of the cam timing needed to get high power. In fact, he showed me a bunch of actual before and after dyno curves for Harley’s modded similar to mine, and two things struck me:

- All of them had a dip in the torque curve

- None of them made more than 100 rwhp

By the way, his dyno is a different brand – a Factory Pro.

Now, a horsepower is supposedly a horsepower, no matter what dyno it was measured on. But if so, why do the best modded Harleys dynode on his dyno still ALL produce significantly less power and torque than the power and torque shown in Harley’s Stage 4 graph? Is the air and fuel around Milwaukee better than elsewhere? ☺

A theory (just a theory) that I would advance to explain the difference in the shape of the curves at the HD dealership and the Indy is that MAYBE the dealership tech ran the dyno tests in 4th gear, whereas the Indy ran it in 5th. The significance is that the entire run at the Indy, for each of the 3 runs, was well under 10 seconds – something like 8 seconds, as I recall from analyzing the Dynojet drf file. IF the HD tech ran his dyno runs in 4th gear, the runs would have been shorter, since the engine can accelerate the dyno drum faster in 4th than in 5th. That of course means the engine also accelerates its own entire drivetrain faster in 4th than in 5th.

But to accelerate the drivetrain, the engine must overcome the COMBINED moment of inertia of the entire drivetrain: flywheel, primary drive, transmission, final drive, and rear wheel. The engine never “gets credit” for producing that power consumed to spin up the drivetrain from the bottom of the engine rpm range all the way to the top, because that diverted power never gets to the dyno drum.

The combined moment of inertia for a Harley drivetrain is very high, because you need big heavy driveline components when your engine is a low rpm high torque engine, versus the high rpm, low torque engines used in most Japanese, Korean, and European bikes. If they aren’t big and heavy, the break under the big torque loads.

The moment of inertia on my Breakout is higher than stock too, since I have the chrome Turbine wheel, which is very heavy, both because it is a billet wheel, and because it is very wide – it mounts a 240 tire.

Furthermore, the diversion of power from spinning up the dyno drum to spinning up the drivetrain is going to have a PROPORTIONATELY greater effect at the lower end of the rpm rnage on the dyno, than at the high end, since there is far less TOTAL engine power available at low rpm than at high rpm.

It seems logical therefore that the diversion of some of the engine’s power to overcome drivetrain moment of inertia would tend to lower the power and therefore torque curves proportionately more at lower rpm than at high rpm. That COULD explain why the torque curve seems a bit low at lower rpm. Equally importantly, it could explain why the HD dealership’s dyno curves show MORE of that lower-torque-at-lower-rpm effect, IF they ran their tests in 4th gear.

Of course, I don’t know what gear the HD dealership ran the dyno tests in, since they wouldn’t give me the Dynojet .drf file (which would clearly show what gear they ran the tests in).

Conclusions:

After all the above, here is what I am personally concluding:

- HD’s Screamin’ Eagle dyno charts, or at least the one for the 103 Stage 4 Race kit, are untrustworthy. You cannot count on getting the results they predict, which makes them useless

- The Stage4 race kit is still worth getting, because it transforms the engine from “weak” to “satisfying”, but its cost per achieved horsepower is way higher than HD’s chart would lead you to believe

- The same brand of dyno at two different shops will not necessarily produce the same dyno curves for the same bike

- Dyno curves cannot be trusted to accurately guide exhaust system experiments

- Some dyno operators are way more knowledgeable, skilled, and comprehensive than others

- A dyno TUNE is REALLY worth getting

Jim G

Last edited by JimGnitecki; 05-04-2014 at 10:52 AM.

The following users liked this post:

Ronbo1 (12-31-2020)

#5

No one should fully trust ANY dyno chart from someone selling a product. Be it FM or HD, etc.

There are way better options, for the same money, than a MOCO STage 4 kit.

If the weather, temp, baro is different, the results will be different. It is ALWAYS worthwhile to review BOTH the SAE and the STD charts. Again, it will be a 'math related' issue when the SAE is above 1.01 or below .99. Dyno is nothing but a tool. Weather, temp, humidity and baro effect any tune, and it's final numbers. Another thing that can alter numbers slightly is various ways to intentionally, or unintentionally 'cheating'. Final numbers will be inflated a teenie bit is the brake temp is 400 as compared to 200.

The true purpose of using a dyno is to TUNE... not any final number or curve, per se. It ALL ends up all about the data. Dyno will consistently gather better, more usable data than any DIY method. I have to get Pine Tree up here and show him, for example.

Dyno curves CAN be used to pick pipes, but pipes mean costs... If someone has done any back-to-back, it MUST involve retuning the bike completely with each pipe change or the charts are worthless.

Bottom line is this... a knowledgeable dyno tuner beats a HD shop's dyno operator everytime. To tune with? A dyno MUST have some kind of brake. A lot of dyno shops still tune as if they are tuning a power commander... and they are not. Flash tuners take a completely different approach.... eg: VEs, vs tuning AFRs. Like anything else... there is a small amount of terrible tuners, a small amount of great tuners and then the majority falls in the middle somehow.

Taking myself as an example... I'm in the middle of things, but HOPE it is the top of the middle! Numbers will not matter, and I tell folks to not be expecting a certain number. Instead, expect a smooth running bike with very nice riding manners instead. Because certain areas are 'hard to get' does NOT mean they should be bypassed. Complete data, means a way better tune. If one gets VEs all lined out at say 1500 rpms and up? And most VEs lined out below 1500 all the way to 800 rpms... the tune will simply be 'better'. It just is.

Numbers will not matter, and I tell folks to not be expecting a certain number. Instead, expect a smooth running bike with very nice riding manners instead. Because certain areas are 'hard to get' does NOT mean they should be bypassed. Complete data, means a way better tune. If one gets VEs all lined out at say 1500 rpms and up? And most VEs lined out below 1500 all the way to 800 rpms... the tune will simply be 'better'. It just is.

Quit worrying the numbers at all. The curves ARE what one looks at. Curves are a general kind of thing, too. Same bike, same dyno, different day? Things will change. I own a dyno, I see this. I do NOT practice ANY cheats. Intentional or otherwise. I run the proper software for my dyno (it is dyno specific to match the drum weight.... some will run software for a heavier drum and the numbers WILL improve.)

Oh, BTW, anybody who says that a fuel dip is OK ... well... it is NOT. WOT fueling should be whats called out, period. Something like that is fully fixable, and time consuming, at least a little. Exhaust dips, OTOH are what they are and it IS reversion. Some, but not all, reversion can be tuned out, too.

I have, as of yet, seen a very good pipe=vs-pipe shootout. One that each pipe has been fully tuned to the bike. One can only compare similar builds and guess.

That being said, there are some systems that do good each time out and tend to be relied upon. Most, if not all of these 'relied upon' pipes are Bagger pipes. Those with non Bagger bikes are at a distinct disadvantage in this regards. Since Touring frames are where all the money is... that is where one sees all the tuning at, too. There is a guy on v-twin who, right now, is comparing dyna pipes using a carb bike. Good info. Bike is 'tuned' for each pipe (jets are changed to best results, etc). NOT the same as EFI, but still shows where a pipe is 'at', for sure. A dyno curve CAN be used to accurately predict what a pipe will do, but one must tread this area highly aware of what can truly be happening.

Sellers of HP? Be it engine 'kits' or cams or pipes? I don't trust them at all, none. I trust the work from various tuners to guide me. And... that does NOT include tuners that tuning is a sideline to shill products. (See what my pipe, cam, ?) can do. There ARE a couple tuners on this site I trust completely. And you, as a member of HDF, will need to gain that knowledge, too. Look at THEIR tunes, and THEIR graphs,etc. A couple, here, would be BVBob and Lonewolfe.

You are on a GOOD path with trying to learn. I commend you, in fact.

And... here IS something you need to understand, but do not. Most do not.

I called out Jamie at FM about a graph he posted. He told me the bike in question was... one of THOSE bikes. Oh, OK.... I'm sorry then, Jamie, because we have seen a few of those,too. One of 'those bikes' is a bike that magically comes out with everything perfectly 'right on' with its specs.

The true reality of things is our bikes are really made like ****. Nothing 21st century in how our bikes are made.... nor designed. Tolerances are held to the level of things in a thousandths of an inch. with specs being quite wide on top of that. 21st century manufacturing at car plants, these days, can be down to the micron level, BTW. ANyways, If one were to take a degree wheel and measure both cams, they will usually find the front and rear cams don't 100% match, nor will either cam match the cam card they were supposedly made from. Cylinders, pistons, and crank placement in block can, and does, change from bike to bike. Some will have the piston exactly level with the cylinder top, while others will have the piston as much as .008" down in the hole. Then... there are the heads. Our heads are made by a multitude of suppliers, and NOT MOCO. Some bike come with extreme core shift problems. Hardly ever do the two heads on the same bike match. The cc's of chamber volume will always be different between two heads. So will the intake ports. Then, even the cylinders are never the same exactly. They use molds to attach the aluminum fins to the steel liners for cylinders. These liners can be: fore or aft, port or starboard of the engine... or any combination of things and... more importantly, the bores them selves can have a taper or be out of round slightly. All of this can add up, subtract from, etc when getting numbers. One of 'those' engines will be one with all really decent parts and how those arts all match up.

I have never owned one of 'those', but have seen them come thru. These are the bikes that simply make more power 100% stock than 90% of all the other bikes. Start with one of these, add cams... and yes, it will be a beast.

I apologized to Jamie, BTW, too. It WAS my bad, on this instance, completely. At that time, Jamie was using a woefully inadequate dyno set up. Today? FM has a state of the art dyno set up and it is vastly vastly improved. I'm jealous for sure.

Folks that sell, if they find one of these, they use it. That's cool and Kosher, etc, from my own perspective, too. But.... the gained results will NOT be typical, either. These sheets make folks expect these numbers, when the numbers are not easily attained. See what I mean?

There are way better options, for the same money, than a MOCO STage 4 kit.

If the weather, temp, baro is different, the results will be different. It is ALWAYS worthwhile to review BOTH the SAE and the STD charts. Again, it will be a 'math related' issue when the SAE is above 1.01 or below .99. Dyno is nothing but a tool. Weather, temp, humidity and baro effect any tune, and it's final numbers. Another thing that can alter numbers slightly is various ways to intentionally, or unintentionally 'cheating'. Final numbers will be inflated a teenie bit is the brake temp is 400 as compared to 200.

The true purpose of using a dyno is to TUNE... not any final number or curve, per se. It ALL ends up all about the data. Dyno will consistently gather better, more usable data than any DIY method. I have to get Pine Tree up here and show him, for example.

Dyno curves CAN be used to pick pipes, but pipes mean costs... If someone has done any back-to-back, it MUST involve retuning the bike completely with each pipe change or the charts are worthless.

Bottom line is this... a knowledgeable dyno tuner beats a HD shop's dyno operator everytime. To tune with? A dyno MUST have some kind of brake. A lot of dyno shops still tune as if they are tuning a power commander... and they are not. Flash tuners take a completely different approach.... eg: VEs, vs tuning AFRs. Like anything else... there is a small amount of terrible tuners, a small amount of great tuners and then the majority falls in the middle somehow.

Taking myself as an example... I'm in the middle of things, but HOPE it is the top of the middle!

Numbers will not matter, and I tell folks to not be expecting a certain number. Instead, expect a smooth running bike with very nice riding manners instead. Because certain areas are 'hard to get' does NOT mean they should be bypassed. Complete data, means a way better tune. If one gets VEs all lined out at say 1500 rpms and up? And most VEs lined out below 1500 all the way to 800 rpms... the tune will simply be 'better'. It just is.

Numbers will not matter, and I tell folks to not be expecting a certain number. Instead, expect a smooth running bike with very nice riding manners instead. Because certain areas are 'hard to get' does NOT mean they should be bypassed. Complete data, means a way better tune. If one gets VEs all lined out at say 1500 rpms and up? And most VEs lined out below 1500 all the way to 800 rpms... the tune will simply be 'better'. It just is.Quit worrying the numbers at all. The curves ARE what one looks at. Curves are a general kind of thing, too. Same bike, same dyno, different day? Things will change. I own a dyno, I see this. I do NOT practice ANY cheats. Intentional or otherwise. I run the proper software for my dyno (it is dyno specific to match the drum weight.... some will run software for a heavier drum and the numbers WILL improve.)

Oh, BTW, anybody who says that a fuel dip is OK ... well... it is NOT. WOT fueling should be whats called out, period. Something like that is fully fixable, and time consuming, at least a little. Exhaust dips, OTOH are what they are and it IS reversion. Some, but not all, reversion can be tuned out, too.

I have, as of yet, seen a very good pipe=vs-pipe shootout. One that each pipe has been fully tuned to the bike. One can only compare similar builds and guess.

That being said, there are some systems that do good each time out and tend to be relied upon. Most, if not all of these 'relied upon' pipes are Bagger pipes. Those with non Bagger bikes are at a distinct disadvantage in this regards. Since Touring frames are where all the money is... that is where one sees all the tuning at, too. There is a guy on v-twin who, right now, is comparing dyna pipes using a carb bike. Good info. Bike is 'tuned' for each pipe (jets are changed to best results, etc). NOT the same as EFI, but still shows where a pipe is 'at', for sure. A dyno curve CAN be used to accurately predict what a pipe will do, but one must tread this area highly aware of what can truly be happening.

Sellers of HP? Be it engine 'kits' or cams or pipes? I don't trust them at all, none. I trust the work from various tuners to guide me. And... that does NOT include tuners that tuning is a sideline to shill products. (See what my pipe, cam, ?) can do. There ARE a couple tuners on this site I trust completely. And you, as a member of HDF, will need to gain that knowledge, too. Look at THEIR tunes, and THEIR graphs,etc. A couple, here, would be BVBob and Lonewolfe.

You are on a GOOD path with trying to learn. I commend you, in fact.

And... here IS something you need to understand, but do not. Most do not.

I called out Jamie at FM about a graph he posted. He told me the bike in question was... one of THOSE bikes. Oh, OK.... I'm sorry then, Jamie, because we have seen a few of those,too. One of 'those bikes' is a bike that magically comes out with everything perfectly 'right on' with its specs.

The true reality of things is our bikes are really made like ****. Nothing 21st century in how our bikes are made.... nor designed. Tolerances are held to the level of things in a thousandths of an inch. with specs being quite wide on top of that. 21st century manufacturing at car plants, these days, can be down to the micron level, BTW. ANyways, If one were to take a degree wheel and measure both cams, they will usually find the front and rear cams don't 100% match, nor will either cam match the cam card they were supposedly made from. Cylinders, pistons, and crank placement in block can, and does, change from bike to bike. Some will have the piston exactly level with the cylinder top, while others will have the piston as much as .008" down in the hole. Then... there are the heads. Our heads are made by a multitude of suppliers, and NOT MOCO. Some bike come with extreme core shift problems. Hardly ever do the two heads on the same bike match. The cc's of chamber volume will always be different between two heads. So will the intake ports. Then, even the cylinders are never the same exactly. They use molds to attach the aluminum fins to the steel liners for cylinders. These liners can be: fore or aft, port or starboard of the engine... or any combination of things and... more importantly, the bores them selves can have a taper or be out of round slightly. All of this can add up, subtract from, etc when getting numbers. One of 'those' engines will be one with all really decent parts and how those arts all match up.

I have never owned one of 'those', but have seen them come thru. These are the bikes that simply make more power 100% stock than 90% of all the other bikes. Start with one of these, add cams... and yes, it will be a beast.

I apologized to Jamie, BTW, too. It WAS my bad, on this instance, completely. At that time, Jamie was using a woefully inadequate dyno set up. Today? FM has a state of the art dyno set up and it is vastly vastly improved. I'm jealous for sure.

Folks that sell, if they find one of these, they use it. That's cool and Kosher, etc, from my own perspective, too. But.... the gained results will NOT be typical, either. These sheets make folks expect these numbers, when the numbers are not easily attained. See what I mean?

Last edited by wurk_truk; 05-04-2014 at 03:32 PM.

#6

So... do NOT ever trust a dyno sheet straight from ANY manufacturer. Us average folks will never see those numbers.

It's best use... a dyno is a tool used for tuning. Placing loads upon a system to mimic riding conditions.

A dyno can out class DIY data collection by quite a degree. (I, myself, would NEVER have believed this, until I saw it with my own personal observations from having bought a dyno in 2012.)

You thinking about gaining parasitic losses is good, but not right. Some dynes have this included in the software, some do not, some meet mid way.

When comparing sheets, look ONLY at Dynojet/ Winpep 7 sheets. This IS the defacto 'sheet'. Any others will need to have a conversion to match the WinPep7 sheets.When dyno shopping, I read all kinds of things. I almost bought a decent looking Superflow dyno. But... I did NOT like how the Superflow uses the drum itself to turn a fan blade to become th dyno fans. I bought a Dynojet 250i, because it is used by the aftermarket industry almost exclusively. It is THE standard of all of the 'sheets' out there. And for me? I find the brake very easy to use for varying tuning applications and tests.

Look at SAE sheets, and if the SAE factor is out by more than 1 either way? You can tend to discount things. DO discount things if the SAE is three points away. An SAE of 1.03 is getting quite shakey. Where the 'weather station' is located IS important. The weather station is where the humidity, baro, temp is determined. I have seen folks place this in a window opening, for example. It is made to be attached to the dyno itself to attempt to read what the bike is actually seeing. One can't tell if a weather station has been moved... but, pay attention the some sheets, and if made the same day, they should reflect that. Before sheet will show 85*F. Funny then the after sheet, same day, will show 75*F, at a later, hotter, part of the day. Funny business is going on, there. Please, discount ANY sheet where the run conditions are not present. And a GOOD shop will place in the bike's condition what gear was used to make the power sheets. They do NOT leave you guessing. And... there is more than one way to start making a sheet. One way is to get the bike to 2000 rpm and let it be stable, hit the record button and whack the throttle all at once. Another way is to apply the bake at 2000 rpms. apply full throttle and allow the bike to stabilize against the brake, hit record and release the brake. I use the first method.

It's best use... a dyno is a tool used for tuning. Placing loads upon a system to mimic riding conditions.

A dyno can out class DIY data collection by quite a degree. (I, myself, would NEVER have believed this, until I saw it with my own personal observations from having bought a dyno in 2012.)

You thinking about gaining parasitic losses is good, but not right. Some dynes have this included in the software, some do not, some meet mid way.

When comparing sheets, look ONLY at Dynojet/ Winpep 7 sheets. This IS the defacto 'sheet'. Any others will need to have a conversion to match the WinPep7 sheets.When dyno shopping, I read all kinds of things. I almost bought a decent looking Superflow dyno. But... I did NOT like how the Superflow uses the drum itself to turn a fan blade to become th dyno fans. I bought a Dynojet 250i, because it is used by the aftermarket industry almost exclusively. It is THE standard of all of the 'sheets' out there. And for me? I find the brake very easy to use for varying tuning applications and tests.

Look at SAE sheets, and if the SAE factor is out by more than 1 either way? You can tend to discount things. DO discount things if the SAE is three points away. An SAE of 1.03 is getting quite shakey. Where the 'weather station' is located IS important. The weather station is where the humidity, baro, temp is determined. I have seen folks place this in a window opening, for example. It is made to be attached to the dyno itself to attempt to read what the bike is actually seeing. One can't tell if a weather station has been moved... but, pay attention the some sheets, and if made the same day, they should reflect that. Before sheet will show 85*F. Funny then the after sheet, same day, will show 75*F, at a later, hotter, part of the day. Funny business is going on, there. Please, discount ANY sheet where the run conditions are not present. And a GOOD shop will place in the bike's condition what gear was used to make the power sheets. They do NOT leave you guessing. And... there is more than one way to start making a sheet. One way is to get the bike to 2000 rpm and let it be stable, hit the record button and whack the throttle all at once. Another way is to apply the bake at 2000 rpms. apply full throttle and allow the bike to stabilize against the brake, hit record and release the brake. I use the first method.

Last edited by wurk_truk; 05-04-2014 at 04:00 PM.

#7

Trending Topics

#8

The On-the-road seat-of the pants-feel, and value of a good dyno tune:

The dyno charts, either of them, may not be very impressive in their numerical values compared to what some others have claimed, and they are puzzling in their difference, but after the dyno tune (not before), the on the road performance is fantastic.

This engine feels so strong at both the bottom of the rpm range and at the top of the rpm range.

The bottom end is particularly impressive. When riding in traffic where I am watching the cars around me intently, I don’t have time to check the tach. When I do get a chance to look, I often find myself riding at 1500 rpm, and quickly downshift! The bike pulls awfully well from low rpm, and cruises at 2000 if I want it to (I prefer to keep the rpm higher just because), despite the cam. Is it the exhaust doing this or?

The top end is a strong rush all the way to the rev limit, with no gaps or surges.

Throttle response is very crisp. In fact, when I blip the throttle to synchronize rpm to road speed on downshifts, it’s as crisp as breaking glass.

Judging by the on the road seat of the pants feel, the HD dealership technician did a pretty good job. I really can’t criticize anything about the feel and performance of the engine.

And, the dyno tune improved the bike’s engine feel astronomically. It feels like an entirely different bike.

Theories: