Drive ratio upgrade HOW TO: Belt Pulleys, Primary sprockets, improve TQ up to 13%

#1

****************************

[[UPDATED March 13 2017]]

****************************

Thread and DIY / HOW TO discussion on getting rid of the factory too tall gearing and improving rear wheel TQ / acceleration by up to 13%.

In short, upgrading your belt pulleys on 2007-up bikes will make your bike faster and accelerate harder. If you have a cam or stage4 upgrade, this will also greatly benefit the overall performance gain. It is the single best 'bang for buck' upgrade on newer bikes in regards to performance gain vs $ spent. There is no associated reduction in MPG and no high revving rpms - Unless of course, you end up with "happy wrist", which will probably be the case here - E.g., you'll actually be able to pass a car in 6th by rolling on without downshifting!

- E.g., you'll actually be able to pass a car in 6th by rolling on without downshifting!

See this informative short post by JimGnitecki who recently did the 30/70 pulley upgrade on his SE Stage IV Breakout. He evaluated MPG / rideability results and it is impressive. https://www.hdforums.com/forum/softa...l#post15022724

HD bikes from 2007-up come from the factory geared too tall on the final drive belt pulleys to help meet ever stricter EPA (and other various) regs. This makes the bike feel pokey and slow in all gears, since the factory rear trans/wheel pulley drive ratio was designed for low emissions, low noise. We can easily get back this stolen power & acceleration at reasonable cost / effort, by changing the front & rear belt pulley sizes to a slightly shorter ratio. This thread will help provide the required DIY and parts info to help you along with the upgrade process. there is NO downside to doing this and No re-tuning of bike needed.

The below upgrades are applicable to all softail / dyna non-touring bikes from 2007 and up (the year HD switched to the lame 32/66 pulleys). I am hoping at some point the touring guys can add their pulley upgrade info to this thread as well. Touring bikes can upgrade but will lose the IDS.

DYNA RIDERS! The info below is relevant to you, and you should also visit this other thread for additional Dyna-specific info. https://www.hdforums.com/forum/dyna-...retted-it.html

There are three pulley upgrade combos that work easily on all softail / dyna with the stock length belts (131t, 132t, 133t)- Best suggested upgrade for the efforts are the 30/68 and 30/70 combos. The 32/70 is NOT suggested as it is too close of a fit and generally a pain, see 2 below. An additional 30/66 combo (6.06% improvement) will only work on Dyna bikes with the 131t belt.

#1 Equals a 3% increase in rear wheel TQ *minor benefit* > 32/68t pulley upgrade, Go to Post #2 below

#2 Equals a 6.07% increase in rear wheel TQ *decent benefit* > 32/70t pulley upgrade, Go to Post #2 below

#3 Equals a 9.9% increase in rear wheel TQ *awesome benefit* > 30t front / 68t rear pulley upgrade, Go to Post #3 below

#4 Equals a 13.1% increase in rear wheel TQ *awesome benefit* > 30t front / 70t rear pulley upgrade, Go to Post #4 below

#5 Equals a 6.67% increase in rear wheel TQ *decent benefit* > 30/66t pulley upgrade, not entirely covered here but post #3 below is very close.

Doing any of these pulley upgrades will require a Powervision or other aftermarket tuner that can modify the speedometer pulse per km so everything reads accurately. I have put the correct speedometer correction setting in each of the specific upgrade posts below.

Generally, to fix your speedometer value all you have to do is look at your stock 'Speedometer Correction' number (VSS), and multiply it by the ratio change to get the new proper valie.

Example: 30/70 is a 13.1% change so you multiply your stock number by 1.131 to get the new number. for the 32/68, multiply your stock number by 1.03, for 32/70 multiply stock number by 1.0607, for 30/68 multiply stock number by 1.097.

If your speedometer reads slightly fast compared to actual speed, lower the number by 10 and re-test.

If your speedometer reads slightly slow compared to actual speed, raise number by 10 and re-test.

I'm mainly going to cover final drive belt pulley upgrades since I have done #1,#3 and #4 myself. Anyone else please feel free to add your upgrades including primary gear ratio changes.

************************************************** ************************************************** ***************************

If you have done this belt pulley or primary gear upgrade to your bike please post what you did, year / model of your bike and your thoughts on the upgrade.

PLEASE POST PICS AND PART NUMBERS if possible! This is an info-building thread. What you post here helps others!

************************************************** ************************************************** **************************

CALCULATOR for checking out the intended pulley or primary gearing changes: www.gearingcommander.com - select "harley", "softail", "Fxsb Breakout" to load the correct gearing data- the data is the same for all current FXS/FXD bikes with exception of the rear tire size- if you have a different size tire then modify the tire data.

Change the "Custom" and "current" drive pulley numbers as appropriate per screenshot below. Add in the "pitch" and length" numbers to see pulley distance changes. This will populate the page result tables with all pertinent data relating to speed, rpm, mph, etc.

-----------------------

Another good gearing ratio > rpm > speed calculator, well laid out and easy to use:

http://woodsware.aciwebs.com/gears/ - load the bike selection for 2014 HD Breakout- Applicable to all years and if you change the tire size, applicable to all current FXS\FXD bikes.

Here is the STOCK gear, rpm, mph data for the stock 32/66 belt pulley combo on the Breakout. Note the max peak TQ and max peak HP rpm's - good to know.

--------------------------

[[UPDATED March 13 2017]]

****************************

Thread and DIY / HOW TO discussion on getting rid of the factory too tall gearing and improving rear wheel TQ / acceleration by up to 13%.

In short, upgrading your belt pulleys on 2007-up bikes will make your bike faster and accelerate harder. If you have a cam or stage4 upgrade, this will also greatly benefit the overall performance gain. It is the single best 'bang for buck' upgrade on newer bikes in regards to performance gain vs $ spent. There is no associated reduction in MPG and no high revving rpms - Unless of course, you end up with "happy wrist", which will probably be the case here

- E.g., you'll actually be able to pass a car in 6th by rolling on without downshifting!

- E.g., you'll actually be able to pass a car in 6th by rolling on without downshifting!See this informative short post by JimGnitecki who recently did the 30/70 pulley upgrade on his SE Stage IV Breakout. He evaluated MPG / rideability results and it is impressive. https://www.hdforums.com/forum/softa...l#post15022724

HD bikes from 2007-up come from the factory geared too tall on the final drive belt pulleys to help meet ever stricter EPA (and other various) regs. This makes the bike feel pokey and slow in all gears, since the factory rear trans/wheel pulley drive ratio was designed for low emissions, low noise. We can easily get back this stolen power & acceleration at reasonable cost / effort, by changing the front & rear belt pulley sizes to a slightly shorter ratio. This thread will help provide the required DIY and parts info to help you along with the upgrade process. there is NO downside to doing this and No re-tuning of bike needed.

The below upgrades are applicable to all softail / dyna non-touring bikes from 2007 and up (the year HD switched to the lame 32/66 pulleys). I am hoping at some point the touring guys can add their pulley upgrade info to this thread as well. Touring bikes can upgrade but will lose the IDS.

DYNA RIDERS! The info below is relevant to you, and you should also visit this other thread for additional Dyna-specific info. https://www.hdforums.com/forum/dyna-...retted-it.html

There are three pulley upgrade combos that work easily on all softail / dyna with the stock length belts (131t, 132t, 133t)- Best suggested upgrade for the efforts are the 30/68 and 30/70 combos. The 32/70 is NOT suggested as it is too close of a fit and generally a pain, see 2 below. An additional 30/66 combo (6.06% improvement) will only work on Dyna bikes with the 131t belt.

- 1> 32t front pulley (stock), and 68t rear pulley (from a 2011-up XL1200 sportster for bikes with 24mm or 1" belt, or from a 2004-2006 Sportster or 2006 Dyna for 1-1/8" belts) - Average upgrade cost = $200-$300, much less if you DIY the labor

-- - 2> 32t front pulley (stock), and 70t rear pulley (from a 2004-2006 FLHT or 2006 Dyna, or aftermarket billet pulley, most all of these are going to be 1-1/8" pulleys which is ok for 20mm, 24mm, 1" or 1-1/8" belts) ** you need to have .61" (roughly 5/8") of available forward swingarm slot adjustment for this to work, see how to measure in post #2** - Average upgrade cost = $200-$700, much less if you DIY the labor and score a deal on the pulley. Billet pulleys can cost upwards of $500. Sometimes you find them on ebay for $100 range new.

**Breakout owners - 2013 bikes with 133t belt should be ok. 2014 and later bikes went to a 132t belt- Your stock rear tire WILL RUB on the inner fender liner with 32/70 - I would suggest either waiting to do the 30t front pulley with the 70t rear, or do the 30/68 pulley combo. No rubbing issue with a 32/68 and 132t belt if you are waiting to do the 30t front later.

-- - 3> 30t front pulley (from a tri-glide), and 68t rear pulley as above in #1 - Average upgrade cost = $700-$900, much less if you DIY the labor and score a deal on the pulley parts. Dealer labor is about the $300-$400 range, front pulley about $80, rear pulley $100-$500

-- - 4> 30t front pulley as above, and 70t rear pulley as above in #2 - Average upgrade cost = same as #3

-- - 5> 30t front pulley as above, and 66t stock rear pulley (Dyna 131t belt only) - Average upgrade cost = same as #3 minus cost / labor of rear pulley

#1 Equals a 3% increase in rear wheel TQ *minor benefit* > 32/68t pulley upgrade, Go to Post #2 below

#2 Equals a 6.07% increase in rear wheel TQ *decent benefit* > 32/70t pulley upgrade, Go to Post #2 below

#3 Equals a 9.9% increase in rear wheel TQ *awesome benefit* > 30t front / 68t rear pulley upgrade, Go to Post #3 below

#4 Equals a 13.1% increase in rear wheel TQ *awesome benefit* > 30t front / 70t rear pulley upgrade, Go to Post #4 below

#5 Equals a 6.67% increase in rear wheel TQ *decent benefit* > 30/66t pulley upgrade, not entirely covered here but post #3 below is very close.

Doing any of these pulley upgrades will require a Powervision or other aftermarket tuner that can modify the speedometer pulse per km so everything reads accurately. I have put the correct speedometer correction setting in each of the specific upgrade posts below.

Generally, to fix your speedometer value all you have to do is look at your stock 'Speedometer Correction' number (VSS), and multiply it by the ratio change to get the new proper valie.

Example: 30/70 is a 13.1% change so you multiply your stock number by 1.131 to get the new number. for the 32/68, multiply your stock number by 1.03, for 32/70 multiply stock number by 1.0607, for 30/68 multiply stock number by 1.097.

If your speedometer reads slightly fast compared to actual speed, lower the number by 10 and re-test.

If your speedometer reads slightly slow compared to actual speed, raise number by 10 and re-test.

I'm mainly going to cover final drive belt pulley upgrades since I have done #1,#3 and #4 myself. Anyone else please feel free to add your upgrades including primary gear ratio changes.

************************************************** ************************************************** ***************************

If you have done this belt pulley or primary gear upgrade to your bike please post what you did, year / model of your bike and your thoughts on the upgrade.

PLEASE POST PICS AND PART NUMBERS if possible! This is an info-building thread. What you post here helps others!

************************************************** ************************************************** **************************

CALCULATOR for checking out the intended pulley or primary gearing changes: www.gearingcommander.com - select "harley", "softail", "Fxsb Breakout" to load the correct gearing data- the data is the same for all current FXS/FXD bikes with exception of the rear tire size- if you have a different size tire then modify the tire data.

Change the "Custom" and "current" drive pulley numbers as appropriate per screenshot below. Add in the "pitch" and length" numbers to see pulley distance changes. This will populate the page result tables with all pertinent data relating to speed, rpm, mph, etc.

-----------------------

Another good gearing ratio > rpm > speed calculator, well laid out and easy to use:

http://woodsware.aciwebs.com/gears/ - load the bike selection for 2014 HD Breakout- Applicable to all years and if you change the tire size, applicable to all current FXS\FXD bikes.

Here is the STOCK gear, rpm, mph data for the stock 32/66 belt pulley combo on the Breakout. Note the max peak TQ and max peak HP rpm's - good to know.

--------------------------

Last edited by LA_Dog; 03-14-2017 at 12:27 AM. Reason: March 13 2017 - corrected info

The following 6 users liked this post by LA_Dog:

ABQ-Jammer (06-10-2019),

FLS103 (09-03-2016),

HoggyMtnBreakdown (03-23-2016),

Reindeer (04-19-2016),

Ryan o (02-19-2018),

and 1 others liked this post.

#2

Upgrade choice #1 AND #2: 32t stock front belt pulley and upgraded 68t OR 70T rear belt pulley

This is the first and easiest upgrade to improve the overall drive ratio. Using your stock 133t or 132t belt, stock 32t front pulley, you will upgrade the rear wheel pulley from 66t to 68t or 70T. This will give you an approximately 3% (68T) or 6% improvement (70T) in overall drive ratio. e.g. a bit quicker acceleration. Applicable to all 2007-up Softail / Dyna bikes. It is more preferable to use the 70T pulley vs the 68T pulley.

*** * Dyna bikes will need a 3/8" wheel spacer to use a sportster 68t pulley, and a 1/2" spacer to use an aftermarket billet 70t pulley. Appropriate length bolts must be purchased so you end up with 1" to 1.25" of bolt thread going into the wheel. pulley spacers are cheap on ebay and any spacer for 2000-up HD will work. You will also appropriate longer bolts to account for the spacer. this added offset spacer is to prevent the belt from contacting the frame when suspension is compressed. ***

*** For the 70T pulley with 32T front combo, please see fitment and pre-check notes below the chart ***

*** Softails including Breakout will run either a 133t or 132t belt. see this post for info on belt length changes - the 132t will NOT fit the 32/70 and will cause tire rubbing issues on the front fender guard. A 133t will fit the 32/70 combo due to slightly longer length. https://www.hdforums.com/forum/softa...l#post15053252

Here is the gear ratio, rpm, mph results for the 32/68 belt pulley combo: charts courtesy of http://woodsware.aciwebs.com/gears/

The charts for the 32T/70T pulley combo and related info are BELOW all of the pictures so scroll down.

Super easy DIY with common tools and the following parts:

FOR BIKES WITH 20mm, 24mm or 1" BELTS (All Softail Bikes and Some Dynas, International models)

1. 2011-up XL1200 Sportster rear pulley PN# 40444-07 (1" wide pulley)

Retail $197 - or - can use PN# 40350-07 as it is still used on the 2013 XL1200 72. the 40350-07 has a machine finish outer rim where the 40444-07 has a black outer rim. both have the machine finish detail on the inner part of outer rim with the black dots. otherwise it's the same pulley.

2. 2011-up XL1200 Sportster pulley bolts (x5)

7/16 - 14 x 1-3/4" PN# 3899 hex bolt with lock patch $1 each. these bolts will be shorter than your stock pulley bolts. NEVER re-use wheel pulley bolts. they are one time use only!

FOR BIKES WITH WIDER 1-1/8" BELTS (Most Dyna bikes- All above Softails can use these wider pulleys too)

1A. 2004-2006 Sportster XL1200 (International) 68T, 1-18" wide Pulley, PN# 40354-04 (see bolts #1A below)

1B. 2006 Dyna (International) 68T, 1-1/8" wide pulley, PN# 40535-06 Black or PN# 40537-06 Silver (see bolts #2B below)

2A. Use the Sportster pulley bolt PN#'s from #1 above

2B. Use the same exact bolt PN#'s you use now on your existing 66T Dyna pulley, please buy a new set of bolts. DO NOT RE-USE BOLTS!

3. five appropriate washers for the bolts (HD has the correct ones) - Applicable to all above.

4. Powervision or other tuner to edit the pulse per km entry for the new drive ratio. New overall drive ratio will be 3% taller, and the speedometer calibration will be 2232 pulse per km for the Breakout with 240 tire. For all other model bikes, just add the ratio percentage increase to your current value. For example, with the 68t rear pulley upgrade it is a 3% ratio increase. multiply your current VSS value by 1.03 and that is the new number. for a 70t rear pulley, 6.07% increase, multiply your VSS by 1.0607 to get the new number. fine tune with a gps as needed. lower VSS by 10 if speedo reads slightly too fast, add 10 to VSS if speedo reads slow. adjust in increments of 10 as needed and re-test.

Be sure to know your torque values and rear wheel removal / reinstall procedures- Use the HD service manual. the below is from the 2013 Softail service manual and should still be applicable to current FXS / FXD bikes.

* Your stock belt guard may not fit with the 68t pulley and definitely will not fit with the 70t pulley. I don't know since I took mine off a long time ago. Something to consider if this is important to you.

---------- HD TQ Specifications-----------------

Rear wheel axle nut TQ = 95-105 ft/lbs

Rear brake caliper bolts TQ = 18-23 ft/lbs

Rear pulley bolts TQ = (first pass) 60 ft/lbs (second pass) 77-83 ft/lbs

--------------------------------------------------

FITMENT and PRE-CHECK for the 70T rear belt pulley with the stock 32T front pulley:

** you need to have minimum 5/8" of available forward swingarm slot adjustment for this to work, be sure to measure first before buying a 70T pulley**

** see suggested 70T pulley part numbers in post #4 below**

**Breakout owners - Your stock rear tire WILL RUB on the inner fender liner with 32/70 - I would suggest either waiting to do the 30t front pulley with the 70t rear, or do the 30/68 pulley combo. No rubbing issue with a 32/68 if you are waiting to do the 30t front later.

---Thanks to member 'Just Enough' for this info and testing fitment on his 2010 CrossBones, located on page 4 of this thread--

Going to a 70T rear pulley with the stock 32T front pulley will net you a 6.07% overall shorter final drive ratio and TQ increase to rear wheel vs stock 32/66 pulleys. This is a significant improvement and twice as good as the 68T rear pulley upgrade. But, you must first measure your available belt slot adjustment remaining since it is a super close fit with the stock 133 belt. We are seeing that stock bikes do have the necessary free slot to support the 70T upgrade gut again it is always wise to check yours first before buying parts. This is how to accurately check your bike:

1. put bike on center stand or jack so it is upright and secure. remove rear axle nut on bike. Break axle nut loose, jack bike up on center jack to take weight off rear wheel, remove axle nut and washer only. The rear wheel will NOT move out of adjustment so no worries there. DO NOT touch the adjuster bolts with the axle nut loose or you'll have to re-align your wheel and re-tighten belt. We are only doing this so you can accurately measure your free forward slot space.

2. measure the available forward slot travel between the front edge of axle and inside forward edge of slot. if you have 5/8" or more of space then you are good to go. after installing the 70T pulley your axle will be pretty much all the way forward in the slot but that is perfectly 100% ok.

3. after measuring tighten up axle nut firmly, torque to 95ft/lbs.

4. After installing the 70T pulley your belt adjuster bolts will be out quite a bit. use some blue loctite on the adjuster threads or get a couple of nuts at the hardware store and thread one on to each of the adjuster bolts all the way up to the bolt head. You'll use these added nuts as "jam nuts" to counter tighten against swingarm, just snug but not too tight. blut loctite or the added nuts will keep the adjuster bolts from possibly falling out while riding.

-------------------------------------------------------

LOTS OF PICS - let page load

***THANK YOU Dynaunder for this suggested upgrade***

Here's some pics of the 40444-07 68t sportster pulley on my stock Breakout wheel- first picture just got it installed on the rim, with my fancy ebay black bolt cover caps of course! ;p

Note the super sweet Pirelli Night Dragon rubber. did I say how much I love these tires??

Second pic shows how much more forward your wheel will sit in the adjuster, and there is plenty of room to properly adjust belt.

The upper blue tape line on swingarm was the OLD adjustment with the stock 66T pulley.

The bottom blue tape line on nut shows the new forward position with the 68T pulley - about a 3/8" difference.

Third pic shows the final belt alignment after running the wheel forward several times to allow the belt to fall into it's natural position (to the outside edge of pulley).

All good, plenty of clearance and nice straight alignment with front pulley. The sportster pulley has the same outboard offset as the stock Breakout pulley.

This was definitely worth the cost of sprocket, bolts and time to put it on.

-------------------------------------

Charts below with gear / mph and rpm data for the 32T/70T pulley combo vs 32T/66T stock. Red and Green numbers are the 32/70 values. Black numbers are the 32/66 stock values:

This is the first and easiest upgrade to improve the overall drive ratio. Using your stock 133t or 132t belt, stock 32t front pulley, you will upgrade the rear wheel pulley from 66t to 68t or 70T. This will give you an approximately 3% (68T) or 6% improvement (70T) in overall drive ratio. e.g. a bit quicker acceleration. Applicable to all 2007-up Softail / Dyna bikes. It is more preferable to use the 70T pulley vs the 68T pulley.

*** * Dyna bikes will need a 3/8" wheel spacer to use a sportster 68t pulley, and a 1/2" spacer to use an aftermarket billet 70t pulley. Appropriate length bolts must be purchased so you end up with 1" to 1.25" of bolt thread going into the wheel. pulley spacers are cheap on ebay and any spacer for 2000-up HD will work. You will also appropriate longer bolts to account for the spacer. this added offset spacer is to prevent the belt from contacting the frame when suspension is compressed. ***

*** For the 70T pulley with 32T front combo, please see fitment and pre-check notes below the chart ***

*** Softails including Breakout will run either a 133t or 132t belt. see this post for info on belt length changes - the 132t will NOT fit the 32/70 and will cause tire rubbing issues on the front fender guard. A 133t will fit the 32/70 combo due to slightly longer length. https://www.hdforums.com/forum/softa...l#post15053252

Here is the gear ratio, rpm, mph results for the 32/68 belt pulley combo: charts courtesy of http://woodsware.aciwebs.com/gears/

The charts for the 32T/70T pulley combo and related info are BELOW all of the pictures so scroll down.

Super easy DIY with common tools and the following parts:

FOR BIKES WITH 20mm, 24mm or 1" BELTS (All Softail Bikes and Some Dynas, International models)

1. 2011-up XL1200 Sportster rear pulley PN# 40444-07 (1" wide pulley)

Retail $197 - or - can use PN# 40350-07 as it is still used on the 2013 XL1200 72. the 40350-07 has a machine finish outer rim where the 40444-07 has a black outer rim. both have the machine finish detail on the inner part of outer rim with the black dots. otherwise it's the same pulley.

2. 2011-up XL1200 Sportster pulley bolts (x5)

7/16 - 14 x 1-3/4" PN# 3899 hex bolt with lock patch $1 each. these bolts will be shorter than your stock pulley bolts. NEVER re-use wheel pulley bolts. they are one time use only!

FOR BIKES WITH WIDER 1-1/8" BELTS (Most Dyna bikes- All above Softails can use these wider pulleys too)

1A. 2004-2006 Sportster XL1200 (International) 68T, 1-18" wide Pulley, PN# 40354-04 (see bolts #1A below)

1B. 2006 Dyna (International) 68T, 1-1/8" wide pulley, PN# 40535-06 Black or PN# 40537-06 Silver (see bolts #2B below)

2A. Use the Sportster pulley bolt PN#'s from #1 above

2B. Use the same exact bolt PN#'s you use now on your existing 66T Dyna pulley, please buy a new set of bolts. DO NOT RE-USE BOLTS!

3. five appropriate washers for the bolts (HD has the correct ones) - Applicable to all above.

4. Powervision or other tuner to edit the pulse per km entry for the new drive ratio. New overall drive ratio will be 3% taller, and the speedometer calibration will be 2232 pulse per km for the Breakout with 240 tire. For all other model bikes, just add the ratio percentage increase to your current value. For example, with the 68t rear pulley upgrade it is a 3% ratio increase. multiply your current VSS value by 1.03 and that is the new number. for a 70t rear pulley, 6.07% increase, multiply your VSS by 1.0607 to get the new number. fine tune with a gps as needed. lower VSS by 10 if speedo reads slightly too fast, add 10 to VSS if speedo reads slow. adjust in increments of 10 as needed and re-test.

Be sure to know your torque values and rear wheel removal / reinstall procedures- Use the HD service manual. the below is from the 2013 Softail service manual and should still be applicable to current FXS / FXD bikes.

* Your stock belt guard may not fit with the 68t pulley and definitely will not fit with the 70t pulley. I don't know since I took mine off a long time ago. Something to consider if this is important to you.

---------- HD TQ Specifications-----------------

Rear wheel axle nut TQ = 95-105 ft/lbs

Rear brake caliper bolts TQ = 18-23 ft/lbs

Rear pulley bolts TQ = (first pass) 60 ft/lbs (second pass) 77-83 ft/lbs

--------------------------------------------------

FITMENT and PRE-CHECK for the 70T rear belt pulley with the stock 32T front pulley:

** you need to have minimum 5/8" of available forward swingarm slot adjustment for this to work, be sure to measure first before buying a 70T pulley**

** see suggested 70T pulley part numbers in post #4 below**

**Breakout owners - Your stock rear tire WILL RUB on the inner fender liner with 32/70 - I would suggest either waiting to do the 30t front pulley with the 70t rear, or do the 30/68 pulley combo. No rubbing issue with a 32/68 if you are waiting to do the 30t front later.

---Thanks to member 'Just Enough' for this info and testing fitment on his 2010 CrossBones, located on page 4 of this thread--

Going to a 70T rear pulley with the stock 32T front pulley will net you a 6.07% overall shorter final drive ratio and TQ increase to rear wheel vs stock 32/66 pulleys. This is a significant improvement and twice as good as the 68T rear pulley upgrade. But, you must first measure your available belt slot adjustment remaining since it is a super close fit with the stock 133 belt. We are seeing that stock bikes do have the necessary free slot to support the 70T upgrade gut again it is always wise to check yours first before buying parts. This is how to accurately check your bike:

1. put bike on center stand or jack so it is upright and secure. remove rear axle nut on bike. Break axle nut loose, jack bike up on center jack to take weight off rear wheel, remove axle nut and washer only. The rear wheel will NOT move out of adjustment so no worries there. DO NOT touch the adjuster bolts with the axle nut loose or you'll have to re-align your wheel and re-tighten belt. We are only doing this so you can accurately measure your free forward slot space.

2. measure the available forward slot travel between the front edge of axle and inside forward edge of slot. if you have 5/8" or more of space then you are good to go. after installing the 70T pulley your axle will be pretty much all the way forward in the slot but that is perfectly 100% ok.

3. after measuring tighten up axle nut firmly, torque to 95ft/lbs.

4. After installing the 70T pulley your belt adjuster bolts will be out quite a bit. use some blue loctite on the adjuster threads or get a couple of nuts at the hardware store and thread one on to each of the adjuster bolts all the way up to the bolt head. You'll use these added nuts as "jam nuts" to counter tighten against swingarm, just snug but not too tight. blut loctite or the added nuts will keep the adjuster bolts from possibly falling out while riding.

-------------------------------------------------------

LOTS OF PICS - let page load

***THANK YOU Dynaunder for this suggested upgrade***

Here's some pics of the 40444-07 68t sportster pulley on my stock Breakout wheel- first picture just got it installed on the rim, with my fancy ebay black bolt cover caps of course! ;p

Note the super sweet Pirelli Night Dragon rubber. did I say how much I love these tires??

Second pic shows how much more forward your wheel will sit in the adjuster, and there is plenty of room to properly adjust belt.

The upper blue tape line on swingarm was the OLD adjustment with the stock 66T pulley.

The bottom blue tape line on nut shows the new forward position with the 68T pulley - about a 3/8" difference.

Third pic shows the final belt alignment after running the wheel forward several times to allow the belt to fall into it's natural position (to the outside edge of pulley).

All good, plenty of clearance and nice straight alignment with front pulley. The sportster pulley has the same outboard offset as the stock Breakout pulley.

This was definitely worth the cost of sprocket, bolts and time to put it on.

-------------------------------------

Charts below with gear / mph and rpm data for the 32T/70T pulley combo vs 32T/66T stock. Red and Green numbers are the 32/70 values. Black numbers are the 32/66 stock values:

Last edited by LA_Dog; 03-20-2017 at 03:32 PM. Reason: added info

The following 4 users liked this post by LA_Dog:

ABQ-Jammer (06-10-2019),

Henboykin (09-02-2023),

HoggyMtnBreakdown (03-23-2016),

Mongo7 (11-14-2021)

#3

Upgrade choice #2: 30t upgraded front belt pulley and 68t upgraded rear belt pulley

>> Applicable to all 2007-up Softail / Dyna bikes, US and International models running 131t, 132t, 133t belts.

>> See 68t rear pulley and belt width fitment notes at beginning of post #2, if you have not yet done the rear pulley upgrade

Second stage of improvement is upgrading the front drive pulley on the transmission to a 30t. this 30t upgrade alone gives 6.67% in ratio improvement over the stock 32t pulley. Combine this with a new 68t rear pulley and you end up with a net 9.9% improvement. Note, Softails with 133t belts will NOT work with the 30t front and stock 66t rear pulley (belt will be too long and will not adjust), but, it works excellent combined with the 68t rear sportster pulley as in post #2 above.

Dyna bikes with shorter 131t belt, this WILL work for your bike.

Some of you with a 132t belt, like my 2013 Breakout and some of the Rockers, can possibly fit 30t/66t with just enough belt adjustment. But, really - if you are here reading this, please go and do BOTH the 30t front AND the 68t or 70t rear pulleys. You will be SO STOKED! And there is ZERO downside. Seriously, you have no idea how good this mod is until after you do it and tune the bike. Wa-Hoo!

Excellent write up on this 30t front belt pulley conversion by member "HD Pilot" located here- pics, info etc:

https://www.hdforums.com/forum/dyna-...y-install.html This info applies equally to Dyna / Softail bikes.

this 30t/68t setup will give you a combined ratio improvement of 9.9% over stock- Definitely noticeable. You'll only be about 150+ rpm higher than stock at freeway 6th gear speeds, and 6th roll ons will be significantly improved (no more dropping to 5th). you'll also find that in the twisties you'll be doing s lot less up/down shifting and 2nd,3rd,4th become way more usable in a wider range. Your bike will feel quicker sort of like riding solo vs 2-up. You won't notice any diff in mpg unless of course your right wrist gets suddenly more aggressive

However- this is the most costly part of the upgrade process as it involves pulling the outer and inner primary. Estimate about $500 including labor, gaskets, 30t pulley.

But! This is a significant and important performance part upgrade especially if you plan to upgrade cams later- performance cams will work much better with an improved overall drive ratio that is closer to the cam's sweet spot. Think about it, no matter how rowdy you build that motor, too tall of gearing will always be your boat anchor. it's simply physics.

Parts:

30 Tooth Tans Sprocket - direct bolt on

2011 Tri Glide Trans Sprocket is HD P/N 83595-11 $63, discount avg. prices HD-83595-11

The Drag Specialties 30 tooth pulley is PN# 12010227 (it's an Andrews pulley, higher price, no benefit).

Andrews pulley part number is 290306

Primary complete gasket kits needed:

Inner kit - Harley Davidson 25700226 GASKET KIT, INNER PRIMARY $43 avg price

Outer kit - JAMES GASKETS, INC. JGI-60547-06-KF GASKET KIT PRIMARY COVER $50 avg price

Labor: Average $350

Speedometer correction: 2372 pulse per km for the Breakout with 240 tire. For all other model bikes, just add the ratio percentage increase to your current value. For example, with a 30t front pulley and 66t rear pulley, it is a 6.7% ratio increase. Multiply your VSS by 1.067 to get the new VSS number. fine tune with a gps as needed. Lower VSS by 10 if speedo reads slightly too fast, add 10 to VSS if speedo reads slow. adjust in increments of 10 as needed and re-test.

Here is the gear ratio, rpm, mph results for the 30/68 belt pulley combo: charts courtesy of http://woodsware.aciwebs.com/gears/

>> Applicable to all 2007-up Softail / Dyna bikes, US and International models running 131t, 132t, 133t belts.

>> See 68t rear pulley and belt width fitment notes at beginning of post #2, if you have not yet done the rear pulley upgrade

Second stage of improvement is upgrading the front drive pulley on the transmission to a 30t. this 30t upgrade alone gives 6.67% in ratio improvement over the stock 32t pulley. Combine this with a new 68t rear pulley and you end up with a net 9.9% improvement. Note, Softails with 133t belts will NOT work with the 30t front and stock 66t rear pulley (belt will be too long and will not adjust), but, it works excellent combined with the 68t rear sportster pulley as in post #2 above.

Dyna bikes with shorter 131t belt, this WILL work for your bike.

Some of you with a 132t belt, like my 2013 Breakout and some of the Rockers, can possibly fit 30t/66t with just enough belt adjustment. But, really - if you are here reading this, please go and do BOTH the 30t front AND the 68t or 70t rear pulleys. You will be SO STOKED! And there is ZERO downside. Seriously, you have no idea how good this mod is until after you do it and tune the bike. Wa-Hoo!

Excellent write up on this 30t front belt pulley conversion by member "HD Pilot" located here- pics, info etc:

https://www.hdforums.com/forum/dyna-...y-install.html This info applies equally to Dyna / Softail bikes.

this 30t/68t setup will give you a combined ratio improvement of 9.9% over stock- Definitely noticeable. You'll only be about 150+ rpm higher than stock at freeway 6th gear speeds, and 6th roll ons will be significantly improved (no more dropping to 5th). you'll also find that in the twisties you'll be doing s lot less up/down shifting and 2nd,3rd,4th become way more usable in a wider range. Your bike will feel quicker sort of like riding solo vs 2-up. You won't notice any diff in mpg unless of course your right wrist gets suddenly more aggressive

However- this is the most costly part of the upgrade process as it involves pulling the outer and inner primary. Estimate about $500 including labor, gaskets, 30t pulley.

But! This is a significant and important performance part upgrade especially if you plan to upgrade cams later- performance cams will work much better with an improved overall drive ratio that is closer to the cam's sweet spot. Think about it, no matter how rowdy you build that motor, too tall of gearing will always be your boat anchor. it's simply physics.

Parts:

30 Tooth Tans Sprocket - direct bolt on

2011 Tri Glide Trans Sprocket is HD P/N 83595-11 $63, discount avg. prices HD-83595-11

The Drag Specialties 30 tooth pulley is PN# 12010227 (it's an Andrews pulley, higher price, no benefit).

Andrews pulley part number is 290306

Primary complete gasket kits needed:

Inner kit - Harley Davidson 25700226 GASKET KIT, INNER PRIMARY $43 avg price

Outer kit - JAMES GASKETS, INC. JGI-60547-06-KF GASKET KIT PRIMARY COVER $50 avg price

Labor: Average $350

Speedometer correction: 2372 pulse per km for the Breakout with 240 tire. For all other model bikes, just add the ratio percentage increase to your current value. For example, with a 30t front pulley and 66t rear pulley, it is a 6.7% ratio increase. Multiply your VSS by 1.067 to get the new VSS number. fine tune with a gps as needed. Lower VSS by 10 if speedo reads slightly too fast, add 10 to VSS if speedo reads slow. adjust in increments of 10 as needed and re-test.

Here is the gear ratio, rpm, mph results for the 30/68 belt pulley combo: charts courtesy of http://woodsware.aciwebs.com/gears/

Last edited by LA_Dog; 03-14-2017 at 12:38 AM. Reason: ratio corrections

The following 6 users liked this post by LA_Dog:

ABQ-Jammer (06-10-2019),

Edders (03-04-2017),

FLS103 (09-03-2016),

Henboykin (01-03-2024),

HoggyMtnBreakdown (03-23-2016),

and 1 others liked this post.

#4

Upgrade choice #3: 30t upgraded front belt pulley and 70t upgraded rear belt pulley- with the stock 133t belt!

Applicable to all 2007-up Softail / Dyna bikes with 24mm, 1" and 1-1/8" belts. 20mm belt bikes will work too you'll just have a wide gap in the pulley alongside the belt as most all 70t pulleys are cut 1-1/8" wide in the belt track.

>> Your stock belt guard will more than likely not fit without modification. Keep this in mind.

This 30/70 combo WILL WORK with the stock Softail / Dyna 131t, 132t, 133t belt lengths. There is just enough adjustment room to install wheel and adjust belt. Attached are rpm / mph graphs of stock 32/66 pulleys vs 30t/70t pulleys from 3k rpm and up. This is actually an easy upgrade as long as you have the right parts ready to go and are familiar with removing / reinstalling a rear wheel. Cost will be determined by the expense of your 70t pulley if you already have the 30t front installed- otherwise you'll need to factor that cost in as well. Bolts & pulley offset spacer is about $30 total. Always use at least Grade 8 pulley bolts and NEVER re-use old pulley bolts.

By going to a 30t front and 70t rear pulley combo, you end up with a net 13% improvement in rear wheel TQ and drive ratio. That is significant and absolutely seat of pants noticeable over stock. However, you still don't get much penalty in freeway rpm. You'll be about 300rpm higher at 80mph vs stock.

Speedometer correction setting: 2392 for the Breakout with 240 tire. For all other model bikes, just add the ratio percentage increase to your current value. For example, with a 30t front pulley and 70t rear pulley, it is a 13.1% ratio increase. Multiply your VSS by 1.131 to get the new VSS number. fine tune with a gps as needed. Lower VSS by 10 if speedo reads slightly too fast, add 10 to VSS if speedo reads slow. adjust in increments of 10 as needed and re-test. With my Pirelli Night Dragon 240 rear tire, I ended up with 2362 for my accurate VSS number. the diameter of the rear tire is considered in the VSS calculation.

Here is the gear ratio, rpm, mph results for the 30/70 belt pulley combo: charts courtesy of http://woodsware.aciwebs.com/gears/

HD 70T factory pulley HD part numbers - This will work with all Softail / Dyna with 20mm, 24mm, 1" and 1-1/8" belts:

>> Dyna will need an additional 1/4" pulley offset spacer so the top of belt does not contact frame when suspension is compressed

>> Softail Breakout and Rocker will need an added 1/8" pulley spacer so belt does not rub tire when walking bike backwards 10ft or more, especially if you are running a 260 tire.

1. 2004-2006 touring FLHT 70T, 1-1/8" wide rear pulley. HD part # 40217-04, cast part # 40117-00

Should fit all 2001-up bikes, 2.25" standard pulley hub.

1A. 2006 FXDB (black) 70T, 1-1/8" wide rear pulley: HD PN# 40576-06. it's 1.125" wide. The pulley itself is stamped with 40581-06

Bolts

For #1 above, you may need slightly longer or shorter bolts than your present stock bolts. You only need to be sure the bolt thread is able to screw into the wheel hub a minimum of 1" and ideally 1.25". All bolts for all wheels are 7/16" 14 thread by varying length. So if your stock bolts are 2-1/4" long then you may need 1-3/4" length bolts instead.

For #1A above, your stock pulley bolts should work. But get a new set of bolts at dealer, DO NOT RE-USE BOLTS!

--------------------------------------------

Aftermarket Billet Pulleys (PM, Ness, DNA, SMC, etc):

Good custom source for 70T billet rear pulleys, prices not bad and they make custom pulleys for any bike: http://www.southern-mc.com/coblsppu.html. Riders with 20mm belts can order the pulley in 1" width.

Arlen Ness - any pulley designed for 2004-2006 FLHT Touring or 2006 Dyna

Ness Black contrast cut models: 16-531 16-950 16-970 16-990 16-976

Ness Chrome models: 16-629 16-501 16-940 16-960 16-980 16-627

Ness Catalog ref: http://issuu.com/arlen_ness/docs/2012_hd_issuu/45

Performance Machine - any pulley designed for 2004-2006 FLHT touring or 2006 Dyna, 70t - !!important note on ALL PM pulleys- the outside hole of the PM pulleys are too small to fit the stock axle spacer. PM wants to sell you a fancy spacer that fits. But, all you have to do is get your stock spacer turned slightly narrower in diameter by a machine shop. You will turn the inside half of the spacer (the side without the two lines on it) smaller in diameter until if fits through the PM pulley opening and has .008 to .010 of a gap.

Other brands of pulley such as DNA, RC Comp, etc can work as long as they are spec'd for the same year model fitment as above. All of these 70T pulleys will be: 1-1/8" belt width, 70 tooth count, 2.25" wheel hub hole, and you WILL need to buy the proper pulley offset spacer. Billet pulleys do not come with the offset spacer molded on like the stock HD pulleys.

Offset spacers:

>>For Softail except Breakout, Rocker: You will need a .250 (1/4") spacer (Drag Specialties pulley spacer for Harley 00-15 2.25" ID model 7805-5051). If you are running a custom wide tire you can get a 3/8" or 1/2" spacer instead for the added tire to belt clearance.

>>For Breakout and Rocker, you will need a 3/8" spacer, especially if you run a 260 tire. this will prevent the belt from rubbing tire when walking bike backwards.

>>For Dyna, you will need a 1/2" spacer so the top of belt does not hit the frame when suspension is compressed.

More bolt info:

Bolts for Arlan Ness pulleys - Need five 7-16" x 1-3/4" 14 thread round head socket cap screw bolts, at least grade 8.

Or, Harley Davidson 7/16"-14 x 1-3/4" hex socket cap head Screw P/N 3542 - hard to find / discontinued. Any bolts purchased should meet or exceed Grade 8 alloy steel. DO NOT use stainless steel bolts.

Good source for cheap high quality bolts - see pic below of bolt bag for company info. they sell small quantities on ebay or direct. Also Zoro or Grainger.

Bolts for Performance Machine pulleys - Same as your stock flat 5 point Harley bolts.

Bolts for other brand of billet pulleys: If the pulley bolt holes are slightly countersunk and round, get the round socket head bolts. If the bolt surface is flat, get the regular 5 point bolts.

For any bolts you buy, you MUST get them long enough so you have 1" to 1.25" of bolt thread going into the wheel. DO NOT use a bolt that has less than 1" of thread going into the wheel. The bolts are the ONLY thing keeping that pulley on and bolt failure can result in death or serious injury.

----------------------------------------

Pulley fitment summary:

I suspect that any 2000-newer softail/dyna 70T pulley that is 1" to 1-1/8" wide will work fine on any other 2001-up bike that runs a 1", 1-1/8", 20mm or 24mm belt- the bolt pattern is same and the hub seat diameter is same on all bikes without IDS (cush drive) from 2000 to present. The only thing you may need, like the Breakout and Dyna owners, is an added wheel spacer and longer bolts. All HD pulleys have a 1/4" spacer actually molded on to the back of the pulley and this offset is good enough for most bikes. Aftermarket billet pulleys assume a custom build and you will use the correct offset spacer.

Dyna owners usually run a 1-1/8" wide belt so be sure to always get a 1-1/8" wide pulley. Most all available 70T pulleys will be 1-1/8" wide. If you have a 20mm, 24mm or 1" wide belt it is ok to run a 1-18" wide pulley.

To put it another way: You can buy any of the chrome design HD or aftermarket billet (RSD, PM, BDL Ness etc) 70t pulleys for a 2004-2006 FLHT or 2006 Dyna - or really, any other 2000-up 70t pulley for HD or custom choppers, and fit it on your current bike. As long as the pulley has the 2.25 hub hole for 2000-up softail/dyna bikes without IDS (cush drive) and is 1" to 1.125" wide (so it fits your belt) you're probably good to go. Worst case you will need a thicker offset spacer and longer bolts. that's pretty much it.

The five hole bolt pattern and bolt type (7/16" 14 thread per inch x needed length) is the same on all non-cush HD's and the axle size or axle spacers do not matter for the pulley (the pulley bolts to wheel hub and never touches axle or wheel spacers).

Once you have the pulley, you would only need to determine the appropriate hub offset spacer and length of bolts- which is not hard to do. Once you have the parts this is no more difficult than replacing a rear pulley.

I wanted to stress these facts so the thought of swapping to another pulley from another year / model of bike does not feel too challenging.

The Breakout belt and many other current model FXS/FXD belts are 24mm wide - 0.98" - So it is fine to run a slightly wider pulley as long as you don't mind seeing a 1/8" gap on inside edge of pulley. Mechanically it is ok though.

Nine large PICS below so let them load:

Arlan Ness pulley #16-531 for a 2004-2006 FLHT (70t, 1.125" wide), Drag Specialties 1/4" pulley spacer, industrial Grade 10 round head socket cap screws 7/16" 14 x 1-3/4"

(you need at least grade 8 for pulley bolts)

Order pulley bolts from American Integrated, phone number is on the 2nd photo (bag of bolts). Best price you'll find and ultra high quality. They have all lengths / sizes.

What I did for this experiment is install the Arlen Ness billet pulley mentioned above, a 1/4" pulley offset spacer from Drag Specialties and five 7/16" 14 x 1-3/4" grade 10 pulley bolts.

I took some pics of parts and the measurement process I used to determine my offset spacer thickness below. Final measurement checking shows that the Arlan Ness pulley with the 1/4" spacer is within 1/32" of the stock pulley height offset. The wheel bolt length was determined based on the thickness of the pulley bolt seat (1/4") and spacer (1/4"), and the need to have 1.25" of bolt thread into the wheel.

Note that if I were using a stock HD pulley like from a 2006 Street Bob or other dyna (also a 70t pulley, 1.125" wide), I might not need the offset spacer since HD molds the spacer into their pulleys. This is why the 2004-2006, or 2011 68T sportster XL1200 pulley is a direct bolt on to other Dyna / Softail bikes even for the Breakout.

DS spacer placed onto backside of Ness pulley:

New round head 7/16" socket cap bolts for pulley - should sit nicely in there.

Measuring and checking pulley offset - stock pulley on stock wheel. lay straight edge across pulley face and measure from ground up to top outside edge of pulley.

your new pulley must sit at that same height so you would get the appropriate thickness spacer to push it outward.

in this case I needed 1/4" and the DS .250" spacer was $9.95

remove stock pulley, place spacer onto wheel hub

place Ness pulley onto wheel, on top of spacer. hold with a couple of bolts.

side view of DS spacer between pulley and wheel hub

checking offset measurement of new pulley and spacer- in this case I am within 1/32" of the stock pulley outward measurement. not bad.

::Everything installed great- no issues - :: - More pics below of the finished install::

UPDATE March 2017 -

Added info from member Dave0176 - He did the 30/70 gearing on his Custom (2009 FXSTC) and it came out awesome.

Link: https://www.hdforums.com/forum/softa...l#post16004484

Here are the parts that he bought for the DIY conversion and should be applicable to all softail 2007-up:

25700337: black inner primary gasket set

83595-11: Tri Glide front pulley

40617-06: 2006 Night Train 70T 20mm rear pulley (you *must* buy the 1/2" pulley spacer to use this specific pulley, since this is one of the few pulleys from HD that has no spacer molded on).

17369-06: primary gasket kit, comes with all seals

9231: Inner primary bearing

Drag specialties 1/2" pulley spacer (for the pulley, as noted above)

*Don't forget the appropriate length rear pulley bolts!

Applicable to all 2007-up Softail / Dyna bikes with 24mm, 1" and 1-1/8" belts. 20mm belt bikes will work too you'll just have a wide gap in the pulley alongside the belt as most all 70t pulleys are cut 1-1/8" wide in the belt track.

>> Your stock belt guard will more than likely not fit without modification. Keep this in mind.

This 30/70 combo WILL WORK with the stock Softail / Dyna 131t, 132t, 133t belt lengths. There is just enough adjustment room to install wheel and adjust belt. Attached are rpm / mph graphs of stock 32/66 pulleys vs 30t/70t pulleys from 3k rpm and up. This is actually an easy upgrade as long as you have the right parts ready to go and are familiar with removing / reinstalling a rear wheel. Cost will be determined by the expense of your 70t pulley if you already have the 30t front installed- otherwise you'll need to factor that cost in as well. Bolts & pulley offset spacer is about $30 total. Always use at least Grade 8 pulley bolts and NEVER re-use old pulley bolts.

By going to a 30t front and 70t rear pulley combo, you end up with a net 13% improvement in rear wheel TQ and drive ratio. That is significant and absolutely seat of pants noticeable over stock. However, you still don't get much penalty in freeway rpm. You'll be about 300rpm higher at 80mph vs stock.

Speedometer correction setting: 2392 for the Breakout with 240 tire. For all other model bikes, just add the ratio percentage increase to your current value. For example, with a 30t front pulley and 70t rear pulley, it is a 13.1% ratio increase. Multiply your VSS by 1.131 to get the new VSS number. fine tune with a gps as needed. Lower VSS by 10 if speedo reads slightly too fast, add 10 to VSS if speedo reads slow. adjust in increments of 10 as needed and re-test. With my Pirelli Night Dragon 240 rear tire, I ended up with 2362 for my accurate VSS number. the diameter of the rear tire is considered in the VSS calculation.

Here is the gear ratio, rpm, mph results for the 30/70 belt pulley combo: charts courtesy of http://woodsware.aciwebs.com/gears/

HD 70T factory pulley HD part numbers - This will work with all Softail / Dyna with 20mm, 24mm, 1" and 1-1/8" belts:

>> Dyna will need an additional 1/4" pulley offset spacer so the top of belt does not contact frame when suspension is compressed

>> Softail Breakout and Rocker will need an added 1/8" pulley spacer so belt does not rub tire when walking bike backwards 10ft or more, especially if you are running a 260 tire.

1. 2004-2006 touring FLHT 70T, 1-1/8" wide rear pulley. HD part # 40217-04, cast part # 40117-00

Should fit all 2001-up bikes, 2.25" standard pulley hub.

1A. 2006 FXDB (black) 70T, 1-1/8" wide rear pulley: HD PN# 40576-06. it's 1.125" wide. The pulley itself is stamped with 40581-06

Bolts

For #1 above, you may need slightly longer or shorter bolts than your present stock bolts. You only need to be sure the bolt thread is able to screw into the wheel hub a minimum of 1" and ideally 1.25". All bolts for all wheels are 7/16" 14 thread by varying length. So if your stock bolts are 2-1/4" long then you may need 1-3/4" length bolts instead.

For #1A above, your stock pulley bolts should work. But get a new set of bolts at dealer, DO NOT RE-USE BOLTS!

--------------------------------------------

Aftermarket Billet Pulleys (PM, Ness, DNA, SMC, etc):

Good custom source for 70T billet rear pulleys, prices not bad and they make custom pulleys for any bike: http://www.southern-mc.com/coblsppu.html. Riders with 20mm belts can order the pulley in 1" width.

Arlen Ness - any pulley designed for 2004-2006 FLHT Touring or 2006 Dyna

Ness Black contrast cut models: 16-531 16-950 16-970 16-990 16-976

Ness Chrome models: 16-629 16-501 16-940 16-960 16-980 16-627

Ness Catalog ref: http://issuu.com/arlen_ness/docs/2012_hd_issuu/45

Performance Machine - any pulley designed for 2004-2006 FLHT touring or 2006 Dyna, 70t - !!important note on ALL PM pulleys- the outside hole of the PM pulleys are too small to fit the stock axle spacer. PM wants to sell you a fancy spacer that fits. But, all you have to do is get your stock spacer turned slightly narrower in diameter by a machine shop. You will turn the inside half of the spacer (the side without the two lines on it) smaller in diameter until if fits through the PM pulley opening and has .008 to .010 of a gap.

Other brands of pulley such as DNA, RC Comp, etc can work as long as they are spec'd for the same year model fitment as above. All of these 70T pulleys will be: 1-1/8" belt width, 70 tooth count, 2.25" wheel hub hole, and you WILL need to buy the proper pulley offset spacer. Billet pulleys do not come with the offset spacer molded on like the stock HD pulleys.

Offset spacers:

>>For Softail except Breakout, Rocker: You will need a .250 (1/4") spacer (Drag Specialties pulley spacer for Harley 00-15 2.25" ID model 7805-5051). If you are running a custom wide tire you can get a 3/8" or 1/2" spacer instead for the added tire to belt clearance.

>>For Breakout and Rocker, you will need a 3/8" spacer, especially if you run a 260 tire. this will prevent the belt from rubbing tire when walking bike backwards.

>>For Dyna, you will need a 1/2" spacer so the top of belt does not hit the frame when suspension is compressed.

More bolt info:

Bolts for Arlan Ness pulleys - Need five 7-16" x 1-3/4" 14 thread round head socket cap screw bolts, at least grade 8.

Or, Harley Davidson 7/16"-14 x 1-3/4" hex socket cap head Screw P/N 3542 - hard to find / discontinued. Any bolts purchased should meet or exceed Grade 8 alloy steel. DO NOT use stainless steel bolts.

Good source for cheap high quality bolts - see pic below of bolt bag for company info. they sell small quantities on ebay or direct. Also Zoro or Grainger.

Bolts for Performance Machine pulleys - Same as your stock flat 5 point Harley bolts.

Bolts for other brand of billet pulleys: If the pulley bolt holes are slightly countersunk and round, get the round socket head bolts. If the bolt surface is flat, get the regular 5 point bolts.

For any bolts you buy, you MUST get them long enough so you have 1" to 1.25" of bolt thread going into the wheel. DO NOT use a bolt that has less than 1" of thread going into the wheel. The bolts are the ONLY thing keeping that pulley on and bolt failure can result in death or serious injury.

----------------------------------------

Pulley fitment summary:

I suspect that any 2000-newer softail/dyna 70T pulley that is 1" to 1-1/8" wide will work fine on any other 2001-up bike that runs a 1", 1-1/8", 20mm or 24mm belt- the bolt pattern is same and the hub seat diameter is same on all bikes without IDS (cush drive) from 2000 to present. The only thing you may need, like the Breakout and Dyna owners, is an added wheel spacer and longer bolts. All HD pulleys have a 1/4" spacer actually molded on to the back of the pulley and this offset is good enough for most bikes. Aftermarket billet pulleys assume a custom build and you will use the correct offset spacer.

Dyna owners usually run a 1-1/8" wide belt so be sure to always get a 1-1/8" wide pulley. Most all available 70T pulleys will be 1-1/8" wide. If you have a 20mm, 24mm or 1" wide belt it is ok to run a 1-18" wide pulley.

To put it another way: You can buy any of the chrome design HD or aftermarket billet (RSD, PM, BDL Ness etc) 70t pulleys for a 2004-2006 FLHT or 2006 Dyna - or really, any other 2000-up 70t pulley for HD or custom choppers, and fit it on your current bike. As long as the pulley has the 2.25 hub hole for 2000-up softail/dyna bikes without IDS (cush drive) and is 1" to 1.125" wide (so it fits your belt) you're probably good to go. Worst case you will need a thicker offset spacer and longer bolts. that's pretty much it.

The five hole bolt pattern and bolt type (7/16" 14 thread per inch x needed length) is the same on all non-cush HD's and the axle size or axle spacers do not matter for the pulley (the pulley bolts to wheel hub and never touches axle or wheel spacers).

Once you have the pulley, you would only need to determine the appropriate hub offset spacer and length of bolts- which is not hard to do. Once you have the parts this is no more difficult than replacing a rear pulley.

I wanted to stress these facts so the thought of swapping to another pulley from another year / model of bike does not feel too challenging.

The Breakout belt and many other current model FXS/FXD belts are 24mm wide - 0.98" - So it is fine to run a slightly wider pulley as long as you don't mind seeing a 1/8" gap on inside edge of pulley. Mechanically it is ok though.

Nine large PICS below so let them load:

Arlan Ness pulley #16-531 for a 2004-2006 FLHT (70t, 1.125" wide), Drag Specialties 1/4" pulley spacer, industrial Grade 10 round head socket cap screws 7/16" 14 x 1-3/4"

(you need at least grade 8 for pulley bolts)

Order pulley bolts from American Integrated, phone number is on the 2nd photo (bag of bolts). Best price you'll find and ultra high quality. They have all lengths / sizes.

What I did for this experiment is install the Arlen Ness billet pulley mentioned above, a 1/4" pulley offset spacer from Drag Specialties and five 7/16" 14 x 1-3/4" grade 10 pulley bolts.

I took some pics of parts and the measurement process I used to determine my offset spacer thickness below. Final measurement checking shows that the Arlan Ness pulley with the 1/4" spacer is within 1/32" of the stock pulley height offset. The wheel bolt length was determined based on the thickness of the pulley bolt seat (1/4") and spacer (1/4"), and the need to have 1.25" of bolt thread into the wheel.

Note that if I were using a stock HD pulley like from a 2006 Street Bob or other dyna (also a 70t pulley, 1.125" wide), I might not need the offset spacer since HD molds the spacer into their pulleys. This is why the 2004-2006, or 2011 68T sportster XL1200 pulley is a direct bolt on to other Dyna / Softail bikes even for the Breakout.

DS spacer placed onto backside of Ness pulley:

New round head 7/16" socket cap bolts for pulley - should sit nicely in there.

Measuring and checking pulley offset - stock pulley on stock wheel. lay straight edge across pulley face and measure from ground up to top outside edge of pulley.

your new pulley must sit at that same height so you would get the appropriate thickness spacer to push it outward.

in this case I needed 1/4" and the DS .250" spacer was $9.95

remove stock pulley, place spacer onto wheel hub

place Ness pulley onto wheel, on top of spacer. hold with a couple of bolts.

side view of DS spacer between pulley and wheel hub

checking offset measurement of new pulley and spacer- in this case I am within 1/32" of the stock pulley outward measurement. not bad.

::Everything installed great- no issues - :: - More pics below of the finished install::

UPDATE March 2017 -

Added info from member Dave0176 - He did the 30/70 gearing on his Custom (2009 FXSTC) and it came out awesome.

Link: https://www.hdforums.com/forum/softa...l#post16004484

Here are the parts that he bought for the DIY conversion and should be applicable to all softail 2007-up:

25700337: black inner primary gasket set

83595-11: Tri Glide front pulley

40617-06: 2006 Night Train 70T 20mm rear pulley (you *must* buy the 1/2" pulley spacer to use this specific pulley, since this is one of the few pulleys from HD that has no spacer molded on).

17369-06: primary gasket kit, comes with all seals

9231: Inner primary bearing

Drag specialties 1/2" pulley spacer (for the pulley, as noted above)

*Don't forget the appropriate length rear pulley bolts!

Last edited by LA_Dog; 03-08-2017 at 01:15 AM. Reason: added info

The following 4 users liked this post by LA_Dog:

ABQ-Jammer (06-10-2019),

Bobber Boy (02-08-2021),

HoggyMtnBreakdown (03-23-2016),

TerryMcQ (09-13-2020)

#5

Here are some pics of the 70t Ness rear pulley install - 10 LARGE PICS so let page load a bit if needed.

Process was essentially this:

Place bike on lift, jack it up so rear wheel is barely resting on ground

Remove rear brake caliper bolts and slide out caliper (put masking tape on outside edge of caliper body so it does not mark your wheel- it is a close squeeze)

Loosen and remove axle nut, loosen adjusters

Slide out axle

Remove right side 2 spacers (note their orientation and direction)

Slip belt off pulley

Remove brake caliper bracket, push bracket inward and forward until it is free from the swingarm tab- then pivot the front of it up and slide out from side of swingarm. (re-install of this part along with the two right spacers and brake caliper is the trickiest bit of the process- so pay close attention to how you removed these parts- reinstall is just the reverse. or you'll be cussing a bit.)

Remove left side long spacer- note orientation, the side with two grooves on it goes to the inside (wheel).

Roll wheel out from under fender and have your 1/2" ratchet and socket ready to loosen the pulley bolts.

Break the pulley bolts loose esily- Stand wheel up and roll it towards a wall. sit on the wheel with the front of tire against the wall. use 1/2" long ratchet and socket to break the bolts loose. you now have enough leverage to do this easily with the tire pushing against the wall. (tip - you can reinstall the new bolts and TQ them by using this same method!

After bolts are broke loose, lay wheel disc side down on soft flat surface, remove bolts and pulley. you may need to tap the pulley to unseat from hub.

Note- if you need to measure your present pulley for figuring correct offset of the new pulley / spacer, then leave the pulley on right now- see pics below- use a straight edge and ruler to take a measurement from the floor to the top outside edge of pulley. write that measurement down.

When you put on your new pulley you will do the same measurement before bolting on- if the measurement is off more than 1/16" from your first measurement with the stock pulley, then buy the correct thickness spacer to make up the offset difference. You'll also need longer bolts to go with the spacer. You should always have 1.25" of bolt thread going into the wheel. bolts should always be Grade 8 or better, alloy steel NOT stainless.

Prep new bolts with locktight if needed on threads (blue). HD factory bolts come with locktight already on the threads. if you are using a billet pulley like me and need to use industrial 7/16" 14 round socket cap hex bolts and no washers, then you MUST put a dab of lube under the rim of the bolt heads. you don't want the hard alloy bolt biting into the softer billet- it will screw up your TQ of the bolts. see pics below.

make sure pulley and spacer is centered, insert bolts all the way down finger tight. give them an initial light tighten with ratchet just so it is seated and won't move. go around the bolts and do every other one, don't tighten bolts all in a row- e.g. 1,3,5,2,4 same thing when you TQ them.

stand wheel up and roll over against wall, sit on wheel, use TQ wrench to do first TQ pass (60ft lbs) then second TQ pass (75-83 ft lbs).

Spin wheel adjusters on swingarm all the way out. reinstall wheel, put on left spacer first, slip belt over pulley, do right side brake bracket, spacers, slide axle through wheel.

lift bike so rear wheel is off ground, center wheel and adjust belt tension, tighten axle nut to spec (95-105 ft lbs), install rear caliper and bolts. spin wheel forward and belt should track to the outside edge of pulley. reverse spin should track to inside of pulley.

use your tuner to change the speedometer calibration pulse per km to 2392 (for the 30t/70t pulley combo)

This was my belt adjustment with stock 133t belt, 30t front pulley and 68t rear pulley

This is after installing the 70t pulley it's almost all the way front. I actually have adjustment- turned the adjusters out about 4 turns on each side for alignment / belt tension. All good though!

measuring offset height of stock sportster 68t pulley on wheel. the stock breakout pulley is the same offset as this.

1/4" pulley offset spacer sitting on wheel, new 70t Ness pulley will sit on this.

After placing Ness pulley on spacer, measurement showed my offset is within 1/32" of the stock and sportster pulley. perfect. So I basically bought the ness pulley, took a measurement of the stock pulley offset, then ordered the correct thickness pulley spacer and correct length bolts.

blue thread locker and purple anti seize under rim of bolt heads. these are ultra hard alloy bolts and I'm not using washers, so the anti seize is needed to prevent the alloy bolt heads from biting into the billet pulley on TQ. that would be bad.

checking center of pulley on wheel before TQ. Note how the axle, and the wheel spacers, fit fine? the don't even touch the pulley so this is why you can use a wide variety of HD / aftermarket 70T pulleys. As long as the bolt pattern is same (they all are) and the hub size of pulley is same (2.25" all 2001-up bikes), and you measure for the correct offset spacer if needed, you're 100% good.

bolts torqued and wheel ready to go on bike.

new 70t baby! hell yeh. i like the open design of the pulley- sure, it is not an exact match for my wheels- but hey- a $600 pulley for $100? I'll keep it, thanks

Belt tracking of new pulley- nice and straight, same position as stock 66t and 68t sportster pulley. I have 1.8" of inside gap with the slightly wider pulley- but it's not much more than I had with the stock 66t Breakout pulley. the Sportster 68t pulley had the least gap as it was a true 1" width pulley.

Process was essentially this:

Place bike on lift, jack it up so rear wheel is barely resting on ground

Remove rear brake caliper bolts and slide out caliper (put masking tape on outside edge of caliper body so it does not mark your wheel- it is a close squeeze)

Loosen and remove axle nut, loosen adjusters

Slide out axle

Remove right side 2 spacers (note their orientation and direction)

Slip belt off pulley

Remove brake caliper bracket, push bracket inward and forward until it is free from the swingarm tab- then pivot the front of it up and slide out from side of swingarm. (re-install of this part along with the two right spacers and brake caliper is the trickiest bit of the process- so pay close attention to how you removed these parts- reinstall is just the reverse. or you'll be cussing a bit.)

Remove left side long spacer- note orientation, the side with two grooves on it goes to the inside (wheel).

Roll wheel out from under fender and have your 1/2" ratchet and socket ready to loosen the pulley bolts.

Break the pulley bolts loose esily- Stand wheel up and roll it towards a wall. sit on the wheel with the front of tire against the wall. use 1/2" long ratchet and socket to break the bolts loose. you now have enough leverage to do this easily with the tire pushing against the wall. (tip - you can reinstall the new bolts and TQ them by using this same method!

After bolts are broke loose, lay wheel disc side down on soft flat surface, remove bolts and pulley. you may need to tap the pulley to unseat from hub.

Note- if you need to measure your present pulley for figuring correct offset of the new pulley / spacer, then leave the pulley on right now- see pics below- use a straight edge and ruler to take a measurement from the floor to the top outside edge of pulley. write that measurement down.

When you put on your new pulley you will do the same measurement before bolting on- if the measurement is off more than 1/16" from your first measurement with the stock pulley, then buy the correct thickness spacer to make up the offset difference. You'll also need longer bolts to go with the spacer. You should always have 1.25" of bolt thread going into the wheel. bolts should always be Grade 8 or better, alloy steel NOT stainless.

Prep new bolts with locktight if needed on threads (blue). HD factory bolts come with locktight already on the threads. if you are using a billet pulley like me and need to use industrial 7/16" 14 round socket cap hex bolts and no washers, then you MUST put a dab of lube under the rim of the bolt heads. you don't want the hard alloy bolt biting into the softer billet- it will screw up your TQ of the bolts. see pics below.

make sure pulley and spacer is centered, insert bolts all the way down finger tight. give them an initial light tighten with ratchet just so it is seated and won't move. go around the bolts and do every other one, don't tighten bolts all in a row- e.g. 1,3,5,2,4 same thing when you TQ them.

stand wheel up and roll over against wall, sit on wheel, use TQ wrench to do first TQ pass (60ft lbs) then second TQ pass (75-83 ft lbs).

Spin wheel adjusters on swingarm all the way out. reinstall wheel, put on left spacer first, slip belt over pulley, do right side brake bracket, spacers, slide axle through wheel.

lift bike so rear wheel is off ground, center wheel and adjust belt tension, tighten axle nut to spec (95-105 ft lbs), install rear caliper and bolts. spin wheel forward and belt should track to the outside edge of pulley. reverse spin should track to inside of pulley.

use your tuner to change the speedometer calibration pulse per km to 2392 (for the 30t/70t pulley combo)

This was my belt adjustment with stock 133t belt, 30t front pulley and 68t rear pulley

This is after installing the 70t pulley it's almost all the way front. I actually have adjustment- turned the adjusters out about 4 turns on each side for alignment / belt tension. All good though!

measuring offset height of stock sportster 68t pulley on wheel. the stock breakout pulley is the same offset as this.

1/4" pulley offset spacer sitting on wheel, new 70t Ness pulley will sit on this.

After placing Ness pulley on spacer, measurement showed my offset is within 1/32" of the stock and sportster pulley. perfect. So I basically bought the ness pulley, took a measurement of the stock pulley offset, then ordered the correct thickness pulley spacer and correct length bolts.

blue thread locker and purple anti seize under rim of bolt heads. these are ultra hard alloy bolts and I'm not using washers, so the anti seize is needed to prevent the alloy bolt heads from biting into the billet pulley on TQ. that would be bad.

checking center of pulley on wheel before TQ. Note how the axle, and the wheel spacers, fit fine? the don't even touch the pulley so this is why you can use a wide variety of HD / aftermarket 70T pulleys. As long as the bolt pattern is same (they all are) and the hub size of pulley is same (2.25" all 2001-up bikes), and you measure for the correct offset spacer if needed, you're 100% good.

bolts torqued and wheel ready to go on bike.

new 70t baby! hell yeh. i like the open design of the pulley- sure, it is not an exact match for my wheels- but hey- a $600 pulley for $100? I'll keep it, thanks

Belt tracking of new pulley- nice and straight, same position as stock 66t and 68t sportster pulley. I have 1.8" of inside gap with the slightly wider pulley- but it's not much more than I had with the stock 66t Breakout pulley. the Sportster 68t pulley had the least gap as it was a true 1" width pulley.

Last edited by LA_Dog; 01-20-2016 at 09:46 AM. Reason: added info

The following 6 users liked this post by LA_Dog:

ABQ-Jammer (06-10-2019),

Bobber Boy (02-08-2021),

HoggyMtnBreakdown (03-23-2016),

Johnny Goodlife (03-18-2016),

riderdave (01-01-2024),

and 1 others liked this post.

#6

#7

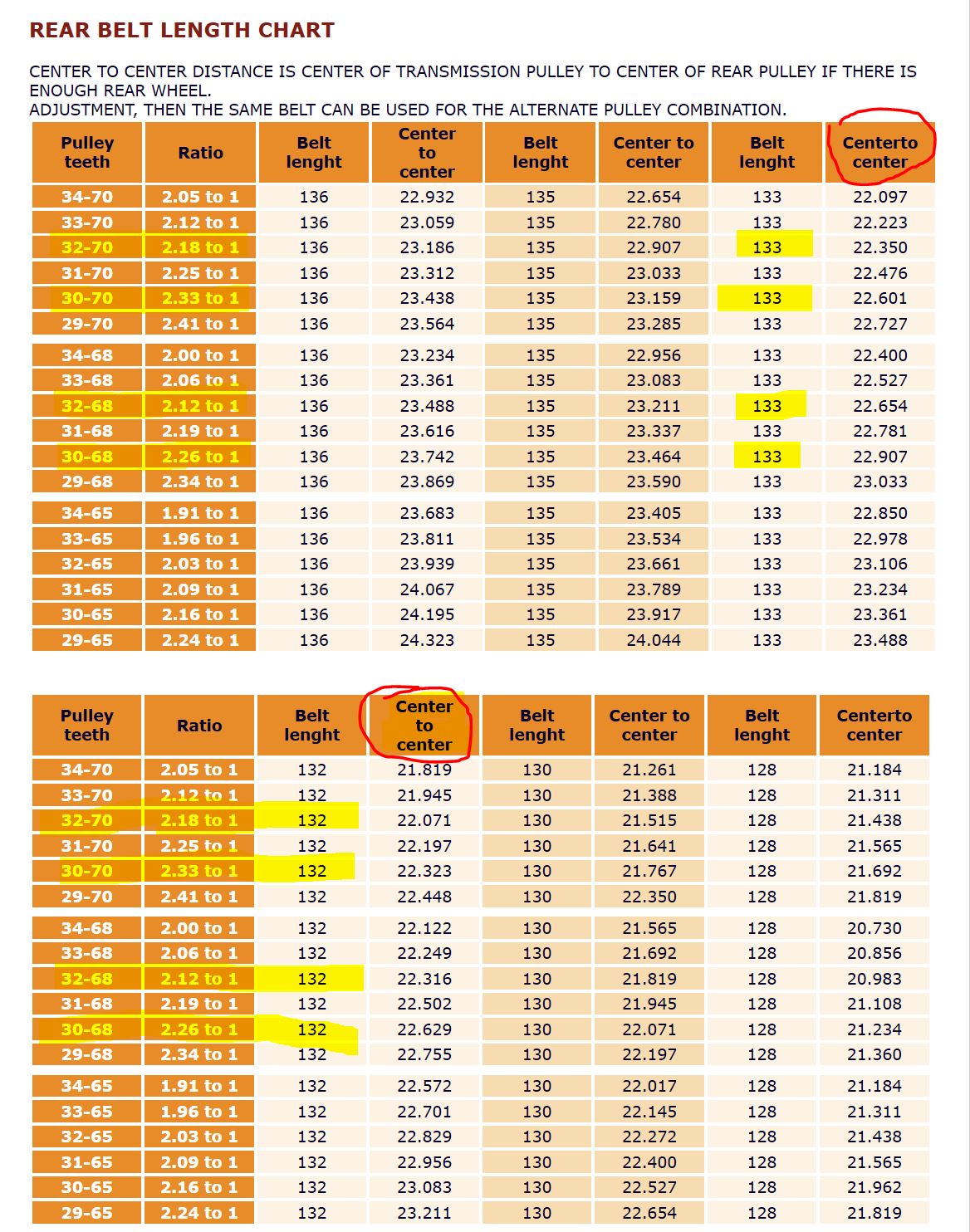

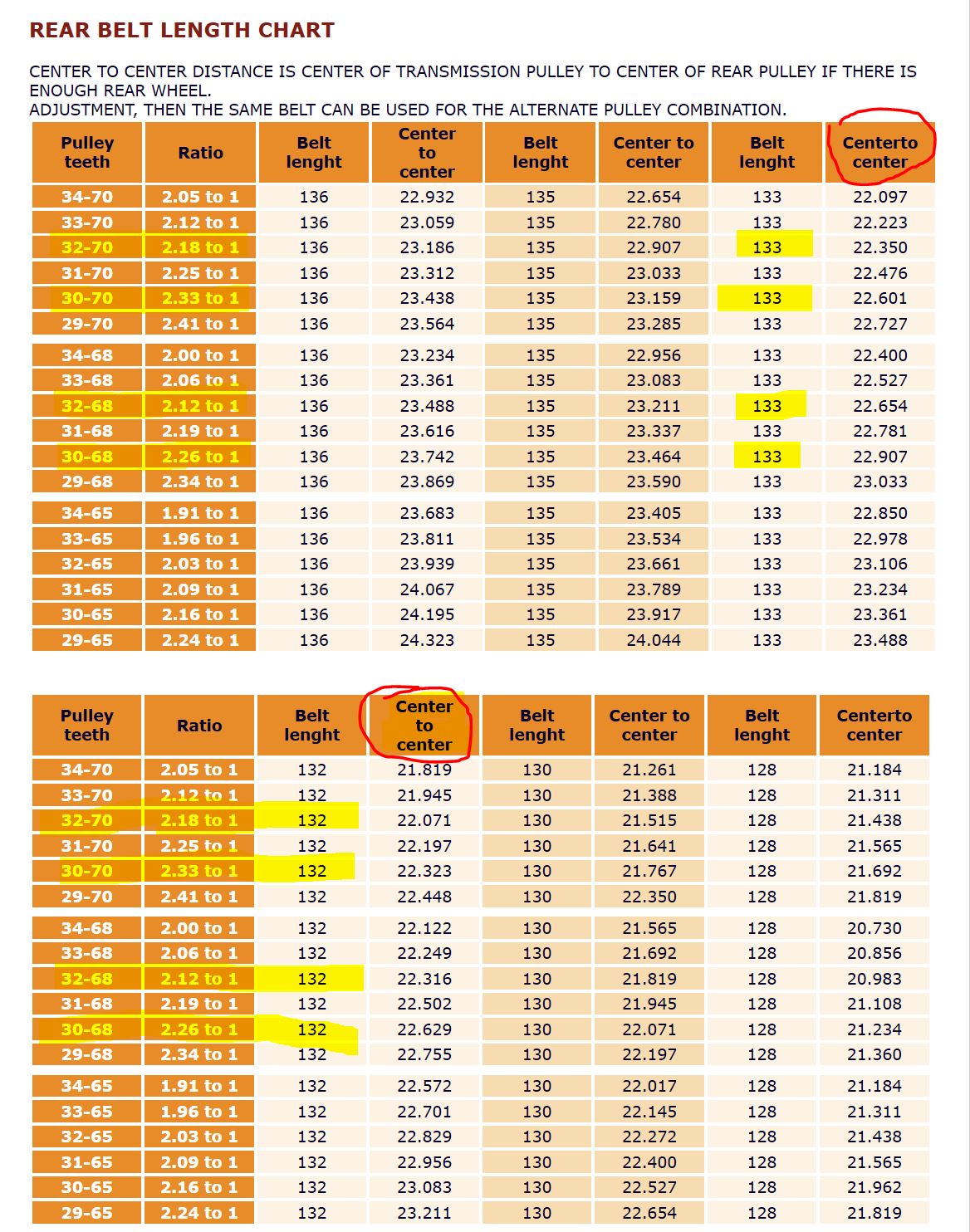

[[[B]EDITED April 18th 2016 - Added belt length chart below for helping to determine your change in belt slot adjustment and also for calculating your speedometer correction.

---------------------------------------------------------------

Below is some info on FINDING YOUR CORRECT NEW VSS NUMBER for speedometer correction after changing pulleys

The TTS MasterTune2-HD software is free to download and install, and it has a "VSS Calculator" built in under the "Tools" menu. Go to the TTS Mastertune website, go to "Downloads", the download the tuning software "MasterTune2-HD.exe". Install software- it will work without the TTS module.

What's IMPORTANT to note here is not just basing the VSS number on the changed gear ratio, but also, the "Tire Rollout" measurement for your bike and installed brand of rear tire. from there you can then calculate the proper VSS speedometer setting. Tire Rollout is slightly smaller than tire diameter based on loading.

The VSS (Speedometer) Calculator

Overview:

The H-D EFI system utilizes a Vehicle Speed Sensor (VSS) device to convey the vehicle's speed to the ECM. The VSS device is mounted on the transmission, and determines road speed by sensing the rate of rotation of a "tone wheel" or gear. This signal is sent to the ECM for processing, then conveyed by the diagnostic bus to the speedometer where it is displayed.

In the ECM, the signal must be "scaled" such that the ECM knows the correct road speed to use in its calculations and to send the correct value to the speedometer. This scaling factor is called the VSS PPU value, and is equal to the number of pulses received from the sensor every 1/25th KM of distance.

The scaling factor can be calculated if one knows the following information:

--

Determining Tire Rollout:

The VSS Calculator utility in TTS MasterTune2-HD software (free to download and install) provides a way to estimate tire rollout by entering a tire size and then calculate the VSS setting based on your vehicle's gearing.

--

Tire rollout is affected by tire construction, wear, inflation pressure, and loading. For this reason, the rollout calculator is only an estimate and may be off 1-2 percent. For the most accurate results, the tire rollout should be measured. This is easily done on any flat surface using the following procedure:

--

Using the VSS Calculator in TTS MasterTune2-HD software:

The VSS calculator is accessed from the main editing form under the "Tools" menu, ."VSS Calculator"

--

First, select the units you want to work in: English or Metric

--

Next, select the vehicle year and model from the drop-down lists. The calculator supports 2001 through current Harley-Davidson vehicles. When a vehicle is selected, the OEM tire and gearing information will populate the form. If this information is not correct, edit it until it matches your vehicle.

--

Calculating Rollout:

To calculate the rollout for a given tire size, select your tire dimensions from the three combo boxes and press Calculate Rollout. This will calculate the following information:

--

Additionally, the Rollout in the VSS section will be updated and the VSS calculation will automatically be run for this combination.

--

Notes:

The Rev/mi and Rollout values are corrected for tire loading, so will not correspond exactly to the mfr's diameter of the tire.

Harley sometimes uses some custom tire sizes on OE tires with no exact "standard" equivalent. Rollout can be estimated using the rolling tape method above.

--

Calculating VSS:

After rollout has been determined, simply enter the transmission and rear sprocket sizes into the form. Press the Calculate VSS button to calculate the VSS value for your vehicle. This value is entered during vehicle programming, refer to Speedometer Calibration for additional information.

--

Examples and common 240 tire sizes: